Method for recovering indium and germanium from zinc leaching residue

A technology of zinc leaching slag and germanium precipitation, applied in the direction of improving process efficiency, etc., can solve the problems of unrecyclable tailings, complicated operation process, high cost, etc., and achieve the effects of stable indicators, short process flow and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

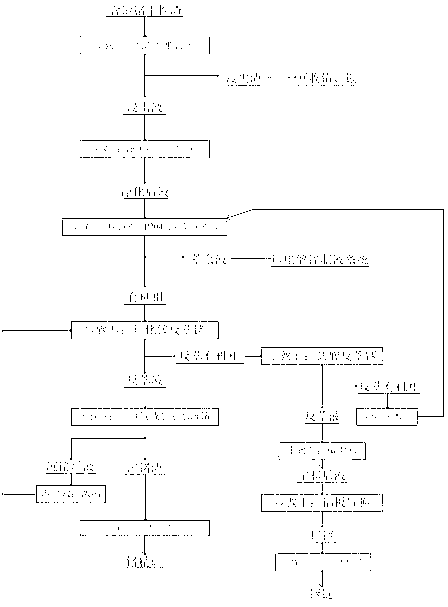

Image

Examples

Embodiment 1

[0061] Use 100 tons of zinc leaching slag from Nandan County, Guangxi, which (containing 0.4% indium and 0.08% germanium) is first added to leaching with 80% concentrated sulfuric acid for 2-3 hours, and the leaching slag is recovered by flotation beneficiation. Lead and silver , the solution is then adjusted according to 0.5~0.6 times w(Fe 3+ ), add iron powder, stir and heat to 55-60°C, react for 1-2h, remove ferric iron, then add 50mg / l industrial gelatin to flocculate and remove silicon, react for 30min, after removing silicon, press water / organic Phase = 4:1 Add hydroxamic acid + P204 kerosene organic phase, synergistically extract indium and germanium at room temperature, and return the raffinate to the electrolytic zinc production system to extract the organic phase for use; the organic phase is based on kerosene: P204 = 8:2, Hydroxamic acid: where P204+kerosene=1-1.25%, extract 99% of indium and germanium, and then add 1mol / l ammonium fluoride to the extracted organic ...

Embodiment 2

[0063] Use 100 tons of zinc leaching slag from Gejiu County, Yunnan Province (containing 0.5% indium and 0.3% germanium) for leaching with 80% concentrated sulfuric acid for 2-3 hours, and use flotation beneficiation to recover lead and silver from the leaching slag. The solution is then adjusted according to 0.5~0.6 times w(Fe 3+ ), add iron powder, stir and heat to 55-60°C, react for 1-2h, remove ferric iron, then add 50mg / l industrial gelatin to flocculate and remove silicon, react for 30min, after removing silicon, press water / organic Phase = 4:1 Add hydroxamic acid + P204 kerosene organic phase, synergistically extract indium and germanium at room temperature, and return the raffinate to the electrolytic zinc production system to extract the organic phase for use; the organic phase is based on kerosene: P204 = 8:2, Hydroxamic acid: where P204+kerosene=1-1.25%; extract 90% of indium and germanium, and then add 1mol / l ammonium fluoride to the extracted organic phase accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com