Method for producing butanol by mixed fermentation of bagasse and molasses serving as raw materials

A technology of mixed fermentation and bagasse, which is applied in the field of bioengineering to achieve high yield and conversion rate and reduce the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The method for producing butanol by mixed fermentation of raw materials with bagasse and molasses of the present invention comprises the steps:

[0020] Step 1, the preparation of bagasse hydrolyzate

[0021] The bagasse is dried at 60°C, crushed and passed through a 40-80 mesh sieve. Hydrolyze with 0.25-3 w / v % dilute sulfuric acid, wherein the solid-liquid ratio of bagasse to dilute sulfuric acid is 8 w / w %, the hydrolysis temperature is 121°C, and the hydrolysis time is 60 minutes. After hydrolysis, neutralize with sodium hydroxide. Then filter the polysaccharide hydrolyzate. DNS method was used to measure the total sugar, and liquid chromatography was used to detect the content of xylose and glucose in the hydrolyzed solution. The results of hydrolysis are shown in Table 1.

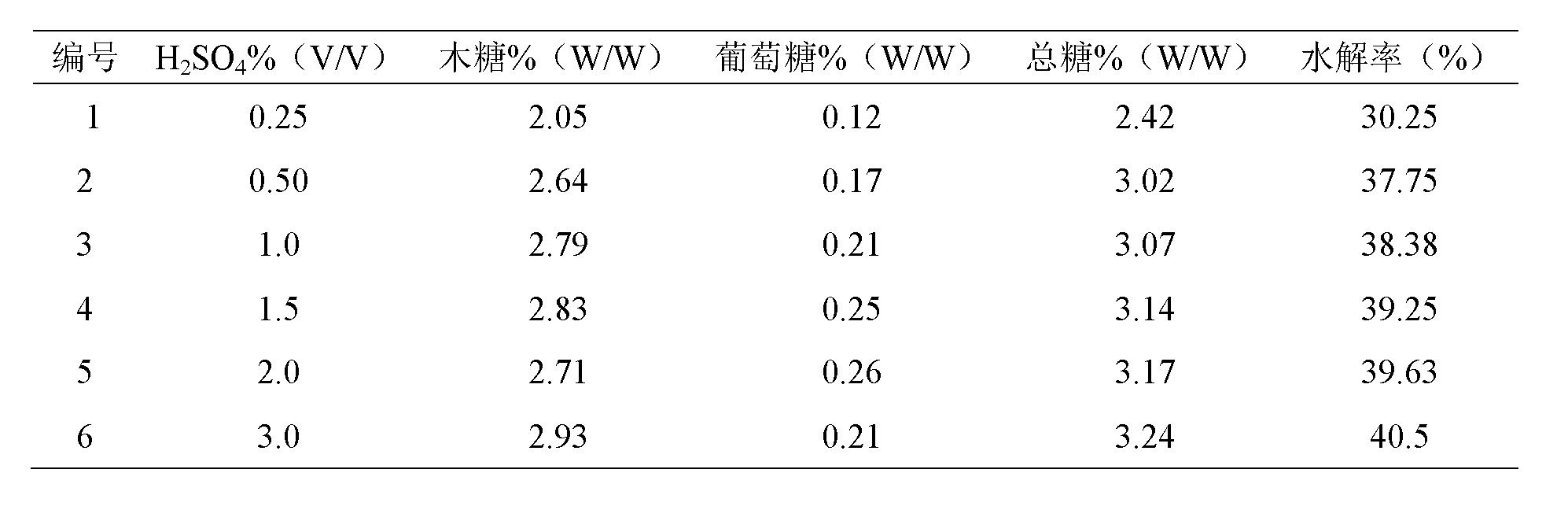

[0022] Table 1 Components and hydrolysis rate of hydrolyzate obtained by hydrolysis of 8% (material-to-water ratio) bagasse with different dilute acid concentrations at 121°C for 1 h

[0023...

Embodiment 2

[0034] Step 1 is the same as in Example 1. Plate culture medium and seed culture medium are the same as embodiment 1.

[0035] Step 2. Clostridium beijerinckii gxas.28 uses bagasse hydrolyzate and molasses as raw materials to produce butanol through mixed fermentation

[0036] Fermentation medium Ⅰ: 80 sag molasses 50g, yeast powder 5g, calcium carbonate 3.0g, superphosphate 0.7g, ammonium sulfate 3.0g, bagasse hydrolyzate prepared by 0.5% volume dilute sulfuric acid to 1000mL, pH 6.2~6.5 . Mix the above ingredients evenly, divide them into 250 mL Erlenmeyer flasks, fill each Erlenmeyer flask with 200 mL, seal with rubber stoppers, and autoclave at 115°C for 15 minutes.

[0037] Fermentation medium Ⅱ: 60g of 80% molasses, 5g of yeast powder, 3.0g of calcium carbonate, 0.7g of superphosphate, 3.0g of ammonium sulfate, dilute sulfuric acid with 0.5% volume of bagasse hydrolyzate to 1000mL, pH 6.2~6.5 . Mix the above ingredients evenly, divide them into 250 mL Erlenmeyer flas...

Embodiment 3

[0044] Plate culture medium and seed culture medium are the same as embodiment 1.

[0045] Clostridium beijerinckii (Clostridium beijerinckii) gxas.28 fermented butanol from glucose, xylose and mixtures.

[0046] Fermentation medium Ⅰ: glucose 60g, beef extract 2g, yeast powder 2g, peptone 6g, ammonium acetate 3g, KH 2 PO 4 0.5g, MgSO 4 ·7H 2 O 0.2g, FeSO 4 ·7H 2 O 0.01 g, agar 20 g, distilled water to 1000mL. Mix the above ingredients evenly, divide them into 250 mL Erlenmeyer flasks, fill each Erlenmeyer flask with 200 mL, seal with rubber stoppers, and autoclave at 115°C for 15 minutes.

[0047] Fermentation medium Ⅱ: xylose 60g, beef extract 2g, yeast powder 2g, peptone 6g, ammonium acetate 3g, KH 2 PO 4 0.5g, MgSO 4 ·7H 2 O 0.2g, FeSO 4 ·7H 2 O 0.01 g, agar 20 g, distilled water to 1000mL. Mix the above ingredients evenly, divide them into 250 mL Erlenmeyer flasks, fill each Erlenmeyer flask with 200 mL, seal with rubber stoppers, and autoclave at 115°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com