Preparation method of graphite-bi-selenylation niobium nanocomposite

A nanocomposite material, niobium diselenide technology, applied in the direction of conductive materials, conductive materials, base materials, etc., can solve the problems that are difficult to meet the market demand, have many problems, affect production efficiency, etc., and achieve a wide range of industrial applications, The effect of small size and excellent tribological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

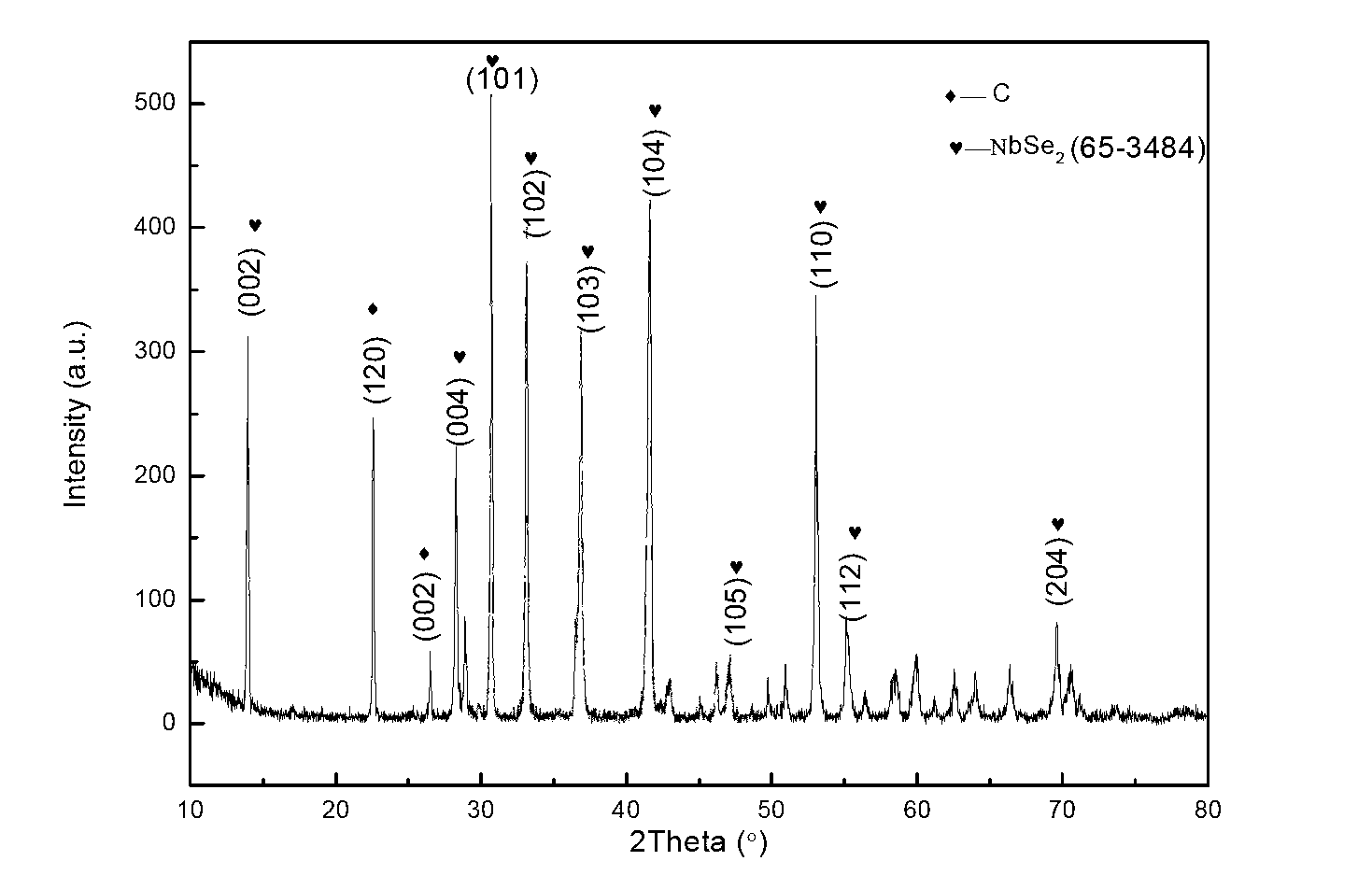

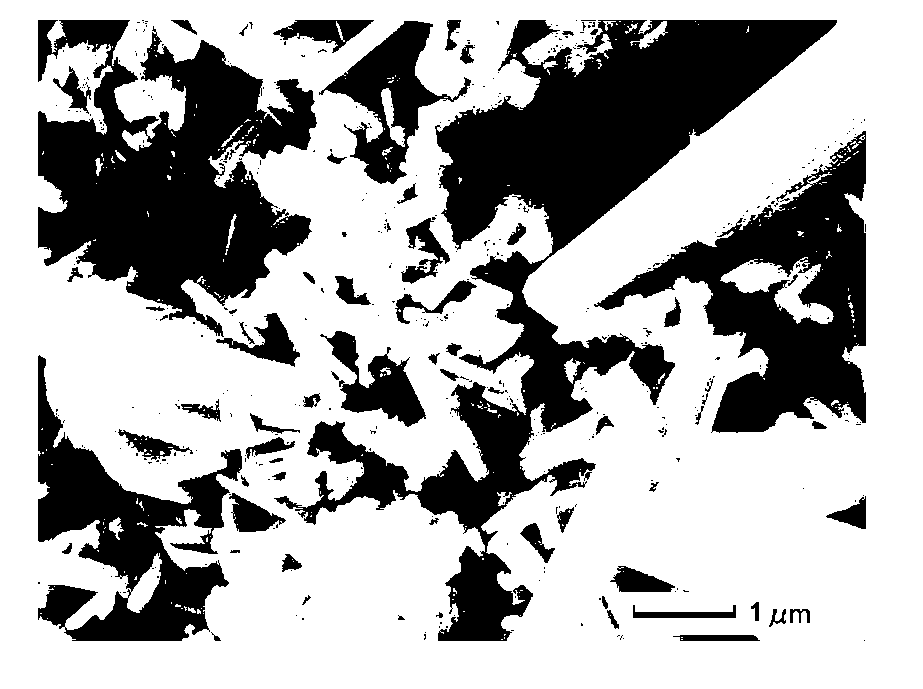

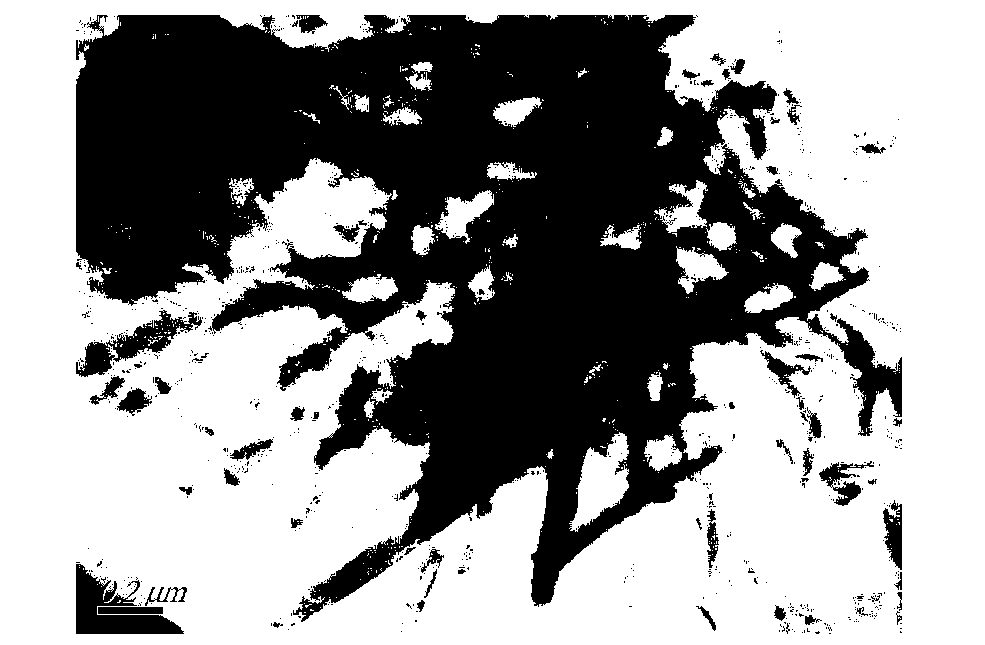

Embodiment 1

[0030] Add 0.60736g of niobium powder, 1.39264g of selenium powder, and 0.45552g of graphite powder into a beaker with 50ml of absolute ethanol, stir magnetically for 2 hours, mix well, let stand, pour out the supernatant, and dry the remaining anhydrous at 75°C Ethanol, put the evenly mixed powder into a self-made reaction kettle, put it into a tubular reaction furnace, raise the temperature to 650°C at a rate of 10°C / min, keep it warm for 2h, and take out the sample after cooling to room temperature with the furnace, and the obtained powder is Graphite-Niobium Diselenide Nanocomposites.

Embodiment 2

[0032] Add 0.60736g of niobium powder, 1.39264g of selenium powder, and 0.45552g of graphite powder into a beaker with 50ml of absolute ethanol, stir magnetically for 2 hours, mix well, let stand, pour out the supernatant, and dry the remaining anhydrous at 75°C Ethanol, put the evenly mixed powder into a self-made reaction kettle, put it into a tubular reaction furnace, raise the temperature to 750°C at a rate of 10°C / min, keep it warm for 2 hours, and take out the sample after cooling to room temperature with the furnace, and the obtained powder is Graphite-Niobium Diselenide Nanocomposites.

Embodiment 3

[0034] Add 0.60736g of niobium powder, 1.39264g of selenium powder, and 0.45552g of graphite powder into a beaker with 50ml of absolute ethanol, stir magnetically for 2 hours, mix well, let stand, pour out the supernatant, and dry the remaining anhydrous at 75°C Ethanol, put the evenly mixed powder into a self-made reaction kettle, put it into a tubular reaction furnace, raise the temperature to 850°C at a rate of 10°C / min, keep it warm for 2 hours, and take out the sample after cooling to room temperature with the furnace, and the obtained powder is Graphite-Niobium Diselenide Nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com