Antistatic master batch and preparation method thereof

A technology of antistatic masterbatch and antistatic agent, applied in the field of antistatic masterbatch for polyester film and its preparation, can solve the problem that the antistatic agent is incompatible with polyester material, the antistatic effect of the film is reduced, and the physical properties of the film are affected. performance and other issues, to achieve the effect of good antistatic effect, easy operation and difficult migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of antistatic masterbatch provided by the invention comprises the steps:

[0050] (1) In terms of parts by mass, the measured polyester chips, nano antistatic agent and antioxidant are added to the twin-screw extruder through a weight loss scale for full mixing, homogenization and devolatilization to obtain molten mixture;

[0051] (2) The molten mixture obtained in step (1) is pressurized by a melt pump, filtered through a filter, and extruded through a die to obtain a strip-shaped molten product; the molten material is cooled by a water tank, and then continuously passed through the The antistatic masterbatch is obtained by drying in a water tank and hot air to remove water, cutting into pellets and packaging.

[0052] The temperature of each zone of the twin-screw extruder is 200-300° C., the rotational speed of the main engine is 200-800 rpm, and the aperture of the filter screen is 20-100 um. The water temperature of the water tank is 5-25°...

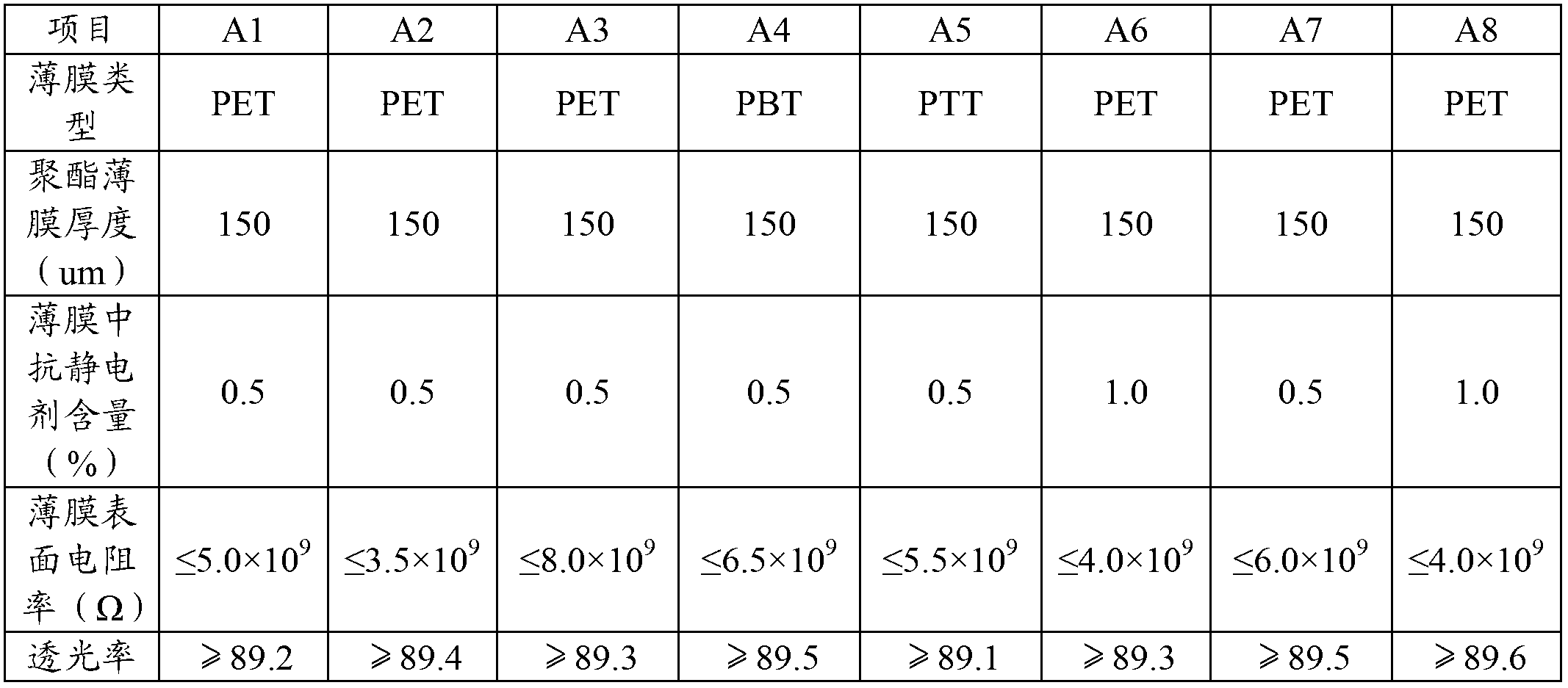

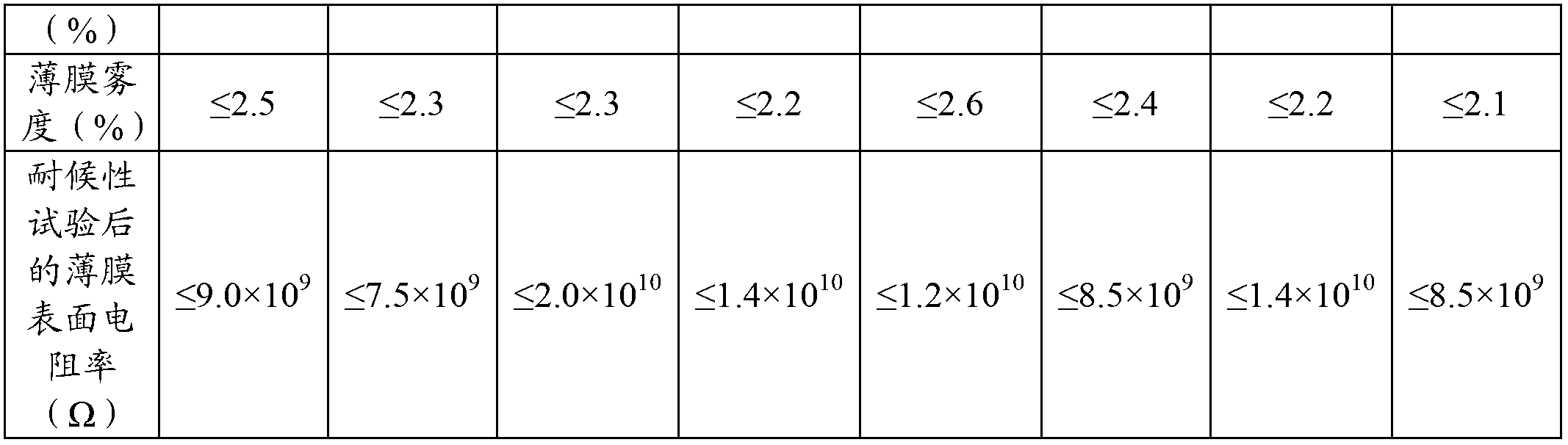

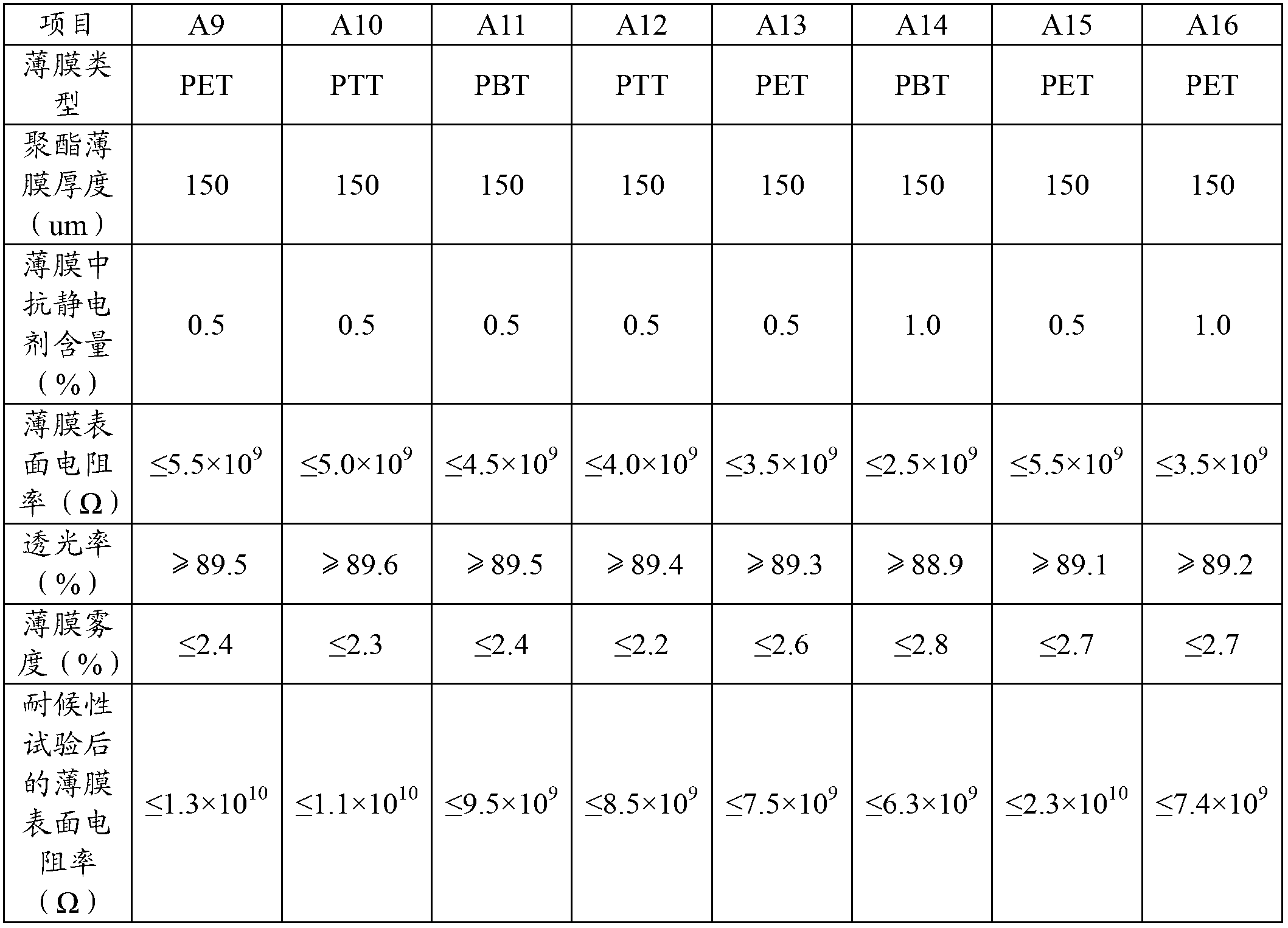

Embodiment 1

[0059] Add 100 parts of PET polyester chips, 30 parts of nano-graphite, 0.1 part of antioxidant 168 and 0.1 part of antioxidant 1010 to the twin-screw extruder through a weight loss scale, prepare antistatic masterbatch according to the above method, and obtain antistatic masterbatch Grain A1.

[0060] The temperature of each zone of the twin-screw extruder is 220-280°C, the speed of the main engine is 600rpm, and the filter screen aperture is 50um.

Embodiment 2

[0062] In terms of parts by mass, 100 parts of PET polyester chips, 40 parts of nano-ATO powder, 0.1 part of antioxidant 168 and 0.1 part of antioxidant 1010 were added to the twin-screw extruder through a weight loss scale, and the antistatic Masterbatch, obtain antistatic masterbatch A2.

[0063] The temperature of each zone of the twin-screw extruder is 220-280°C, the speed of the main engine is 500rpm, and the filter screen aperture is 20um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com