Process method for producing high-purity aluminum oxide and silicate by using pulverized fuel ash

A technology of high-purity alumina and process method, which is applied in the field of producing high-purity alumina and silicate, can solve the problems of high container requirements, waste of resources, and high comprehensive cost, shortening the leaching time period and reducing solid waste. The effect of improving the leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Extraction of alumina and silica from high alumina fly ash

[0025] The chemical composition of high-alumina fly ash samples from a thermal power plant in Inner Mongolia is shown in Table 1.

[0026] Table 1 Chemical composition of high alumina fly ash samples

[0027] Element

Al 2 o 3

SiO 2

total iron oxide

TiO 2

CaO

the sum

Content (%)

48.45

34.99

1.92

1.54

3.64

1.31

91.85

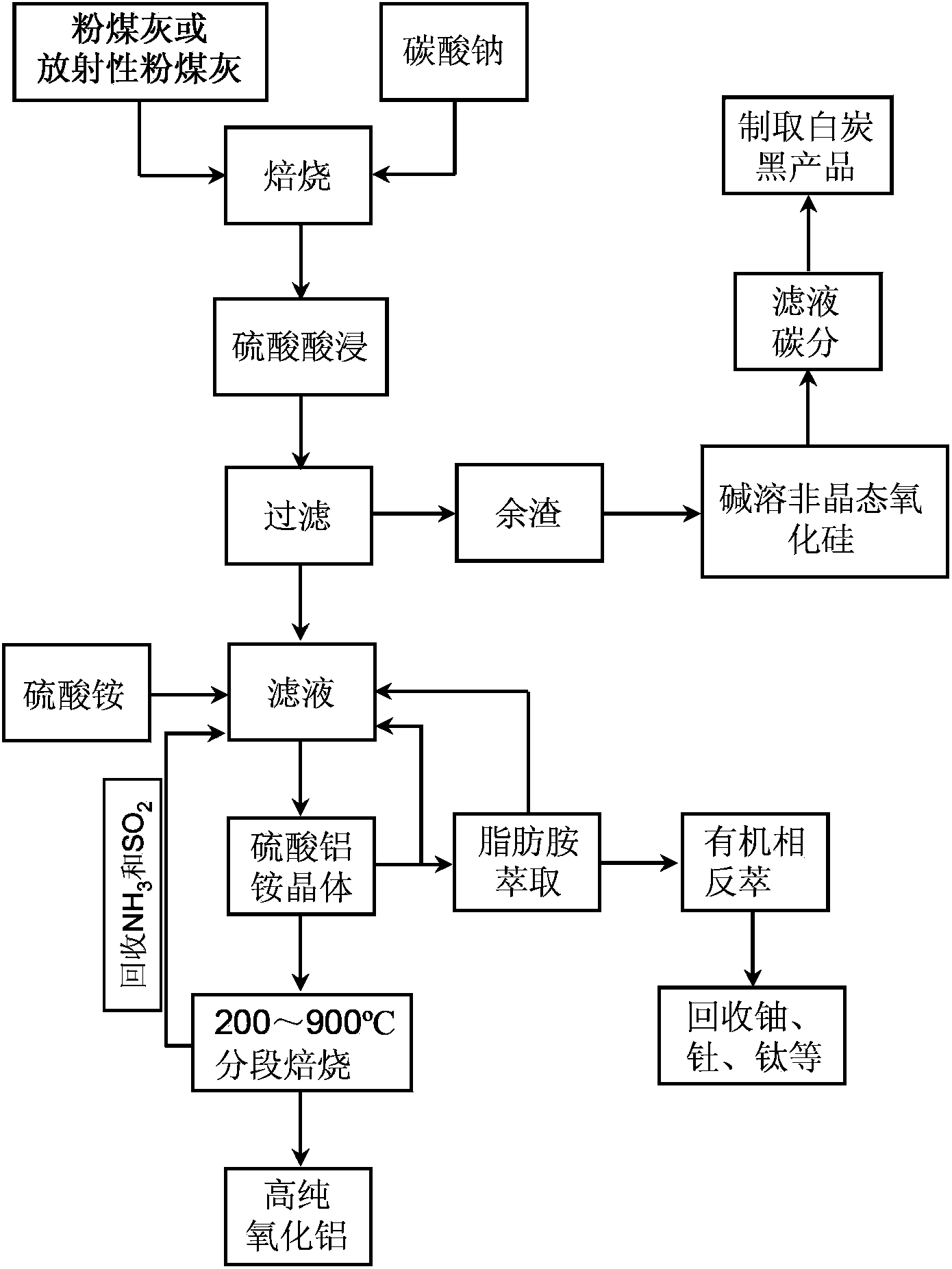

[0028] use figure 1 As shown in the process flow, take 20 grams of high-alumina fly ash ball-milled to -200 mesh, add 7.2 grams of sodium carbonate (Na 2 O-Al 2 o 3 -SiO 2 Na in the ternary system 2 O mass percentage is 20%), mechanically mixed, added 5.4 mL of water to make a slurry, then transferred to a 50 mL corundum crucible, and baked at 900oC for 3 hours. Take it out, cool to room temperature, and wash with 50 mL of water. The filter residue was leached with 100 mL of 4...

Embodiment 2

[0030] Example 2 Extracting alumina from high aluminum fly ash

[0031] The composition of the high alumina fly ash used in this example is the same as that in Example 1. use figure 1 Shown technological process, get ball milling to-200 purpose embodiment one high aluminum fly ash 20 grams, add ball milling to-200 purpose sodium carbonate 15 grams (Na 2 O-Al 2 o 3 -SiO 2 Na in the ternary system 2O mass percentage is 34.5%), mixed mechanically, added 9 mL of water to make a slurry, then transferred to a 50 mL corundum crucible, and baked at 900oC for 2 hours. Take it out, cool to room temperature, and wash with 100 mL of water. The filter residue was leached with 100 mL of 2M sulfuric acid for 1 hour. filter. The filter cake was washed with 100 mL of water. The washings were filtered and combined with the filtrate. Concentrate the leaching solution to 100 mL under heating, then add 60 g of ammonium sulfate and heat to dissolve. Cool to room temperature, filter, wash...

Embodiment 3

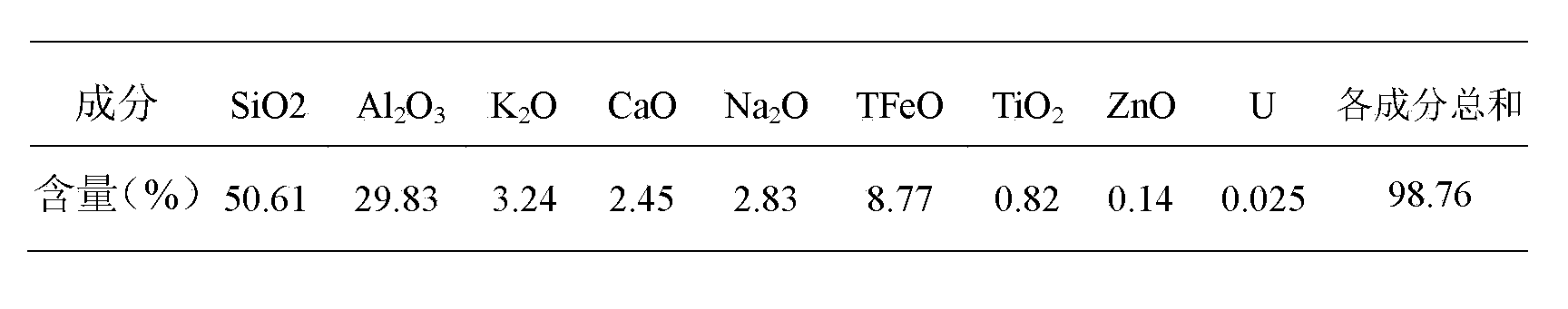

[0032] Example 3 Extraction of alumina and silica from fly ash of thermal power plant

[0033] The chemical composition of the fly ash sample from a thermal power plant in Tianjin is shown in Table 2.

[0034] Table 2 Chemical composition of fly ash samples

[0035] Element

SiO 2

al 2 o 3

K 2 o

CaO

Na 2 o

TFeO

TiO 2

ZnO

sum of ingredients

Content (%)

48.05

37.87

3.16

3.11

2.53

3.34

1.27

0.30

99.63

[0036] use figure 1 As shown in the process flow, take 20 grams of the above fly ash ball milled to -200 mesh and 10 grams of sodium carbonate ball milled to -200 mesh, after mechanical mixing, add 5 mL water to make a slurry, transfer to a 50 mL corundum crucible , baked at 1000oC for 40 minutes. Remove and cool to room temperature. Wash once with 100 mL of water. Then leached with 100mL 6M sulfuric acid for 2 hours. Filter, the filter cake is washed once with 100mL wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com