Flux-cored wire for gas-shielded welding of high-chromium-nickel all-austenitic stainless steel

A fully austenitic, flux-cored welding wire technology, applied in the direction of welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of poor welding process performance, limited, difficult to meet high requirements, high-quality stainless steel welding, etc. problems, to achieve the effect of excellent welding process performance and good weld forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

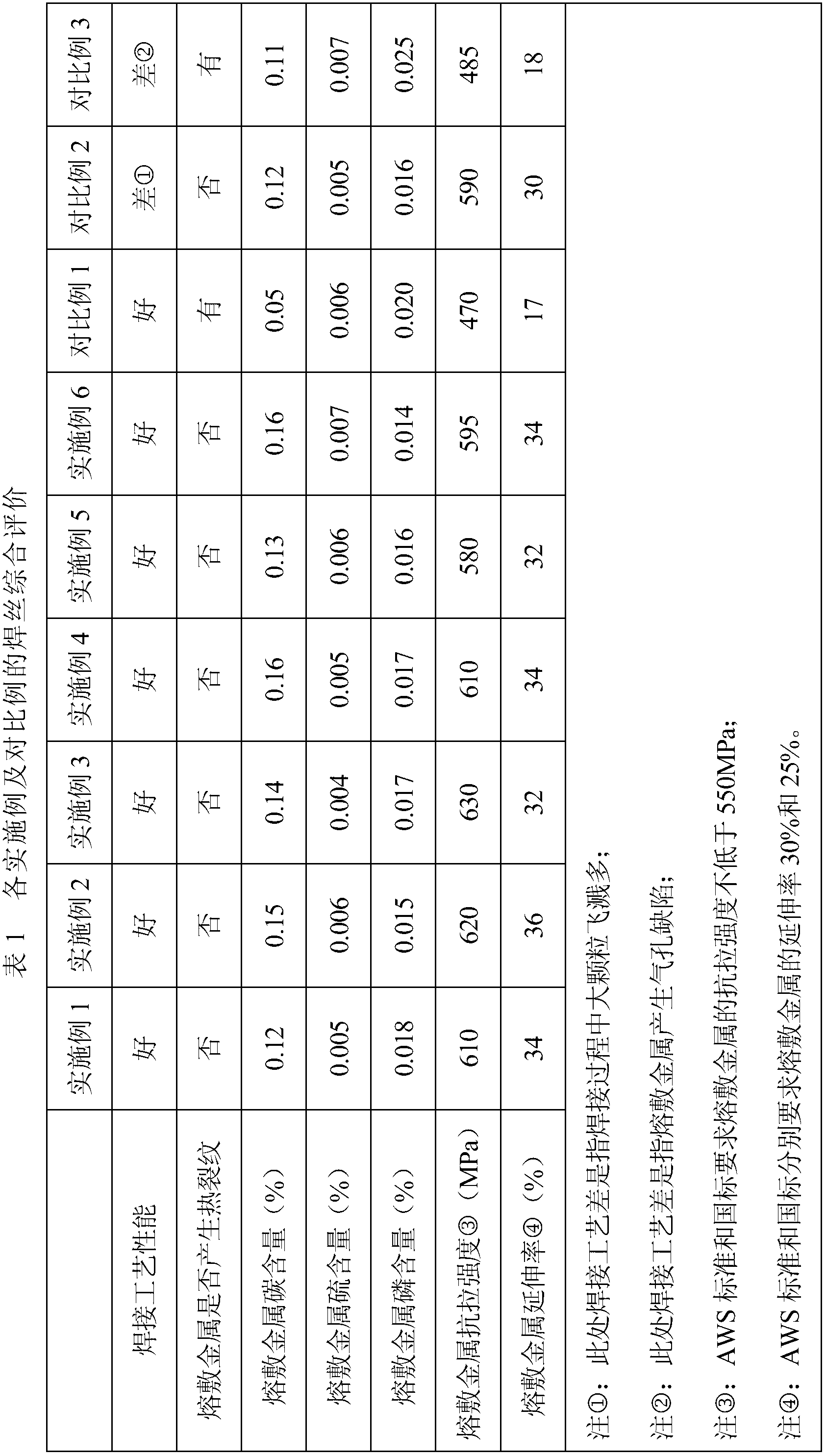

Examples

Embodiment 1

[0046] Select a 309 austenitic stainless steel strip with a thickness of 0.4mm, a width of 10mm, and a weight of 2571g, and roll it into a U shape, 250g of metal chromium powder, 290g of metal nickel powder, 40g of electrolytic metal manganese, 20g of high-carbon ferrochrome, and 180g of rutile , 10g of quartz, 10g of zircon sand, 10g of feldspar, 5g of fluorite, 5g of barium carbonate, 5g of calcium carbonate, 175g of iron powder, a total of 1000g of powder, mixed evenly and added to the U-shaped tank, the filling rate is 28%, after closing After several times of rolling and reducing, the diameter of the final finished welding wire is 1.2mm.

Embodiment 2

[0048] Select a 309 austenitic stainless steel strip with a thickness of 0.4mm, a width of 10mm, and a weight of 2571g, and roll it into a U shape. 280g of metal chromium powder, 320g of metal nickel powder, 50g of electrolytic metal manganese, 40g of high-carbon ferrochrome, and 200g of rutile , 20g of quartz, 20g of zircon sand, 30g of feldspar, 10g of fluorite, 15g of barium carbonate, 10g of calcium carbonate, 5g of iron powder, a total of 1000g of powder, mixed evenly and added to the U-shaped tank, the filling rate is 28%, after closing After several times of rolling and reducing, the diameter of the final finished welding wire is 1.2mm.

Embodiment 3

[0050] Select a 309 austenitic stainless steel strip with a thickness of 0.4mm, a width of 10mm, and a weight of 3448g, and roll it into a U shape, 270g of metal chromium powder, 300g of metal nickel powder, 45g of electrolytic metal manganese, 30g of high-carbon ferrochrome, and 190g of rutile , 15g of quartz, 15g of zircon sand, 30g of feldspar, 8g of fluorite, 8g of barium carbonate, 10g of calcium carbonate, 79g of iron powder, a total of 1000g of powder, mixed evenly and added to the U-shaped tank, the filling rate is 29%, after closing After several times of rolling and reducing, the diameter of the final finished welding wire is 1.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com