Piston ring of chrome-base ceramic composite plating layer

A ceramic composite and piston ring technology, which is applied to piston rings, engine components, machines/engines, etc., can solve the problems of abrasive wear of piston rings, and achieve the effects of ensuring processing performance, low emissions, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

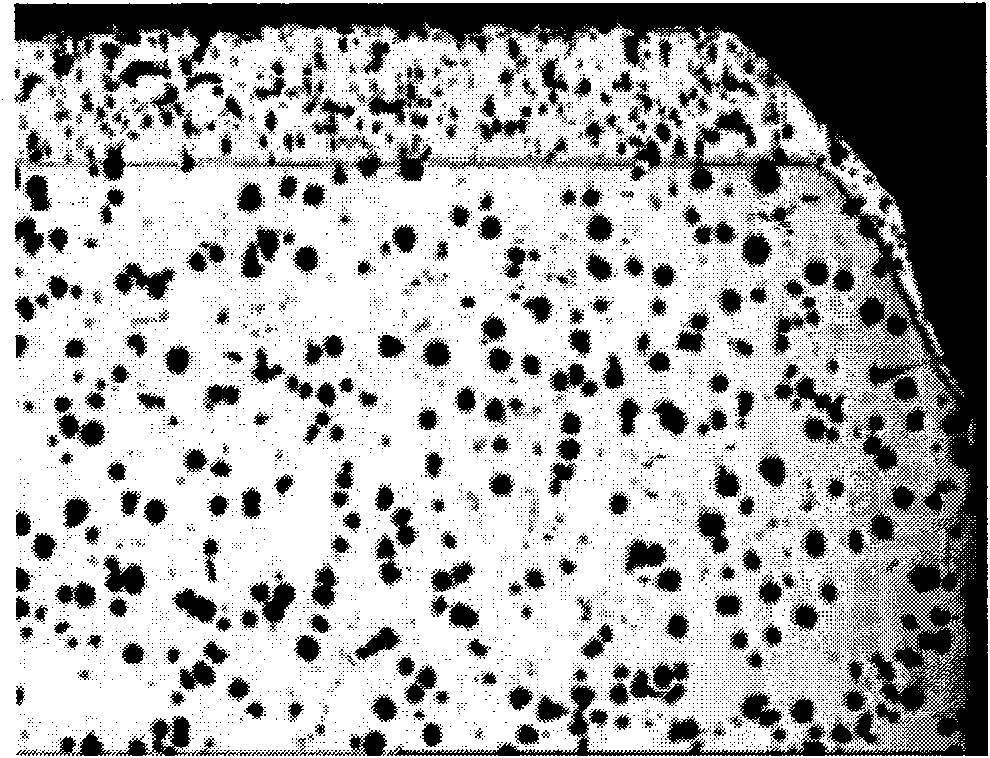

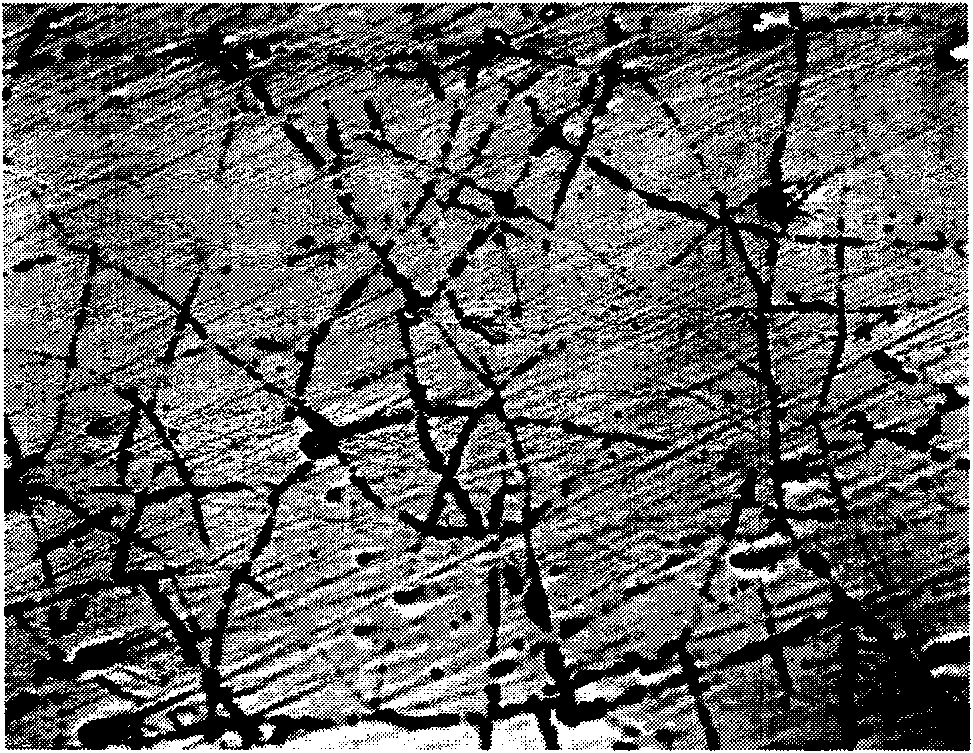

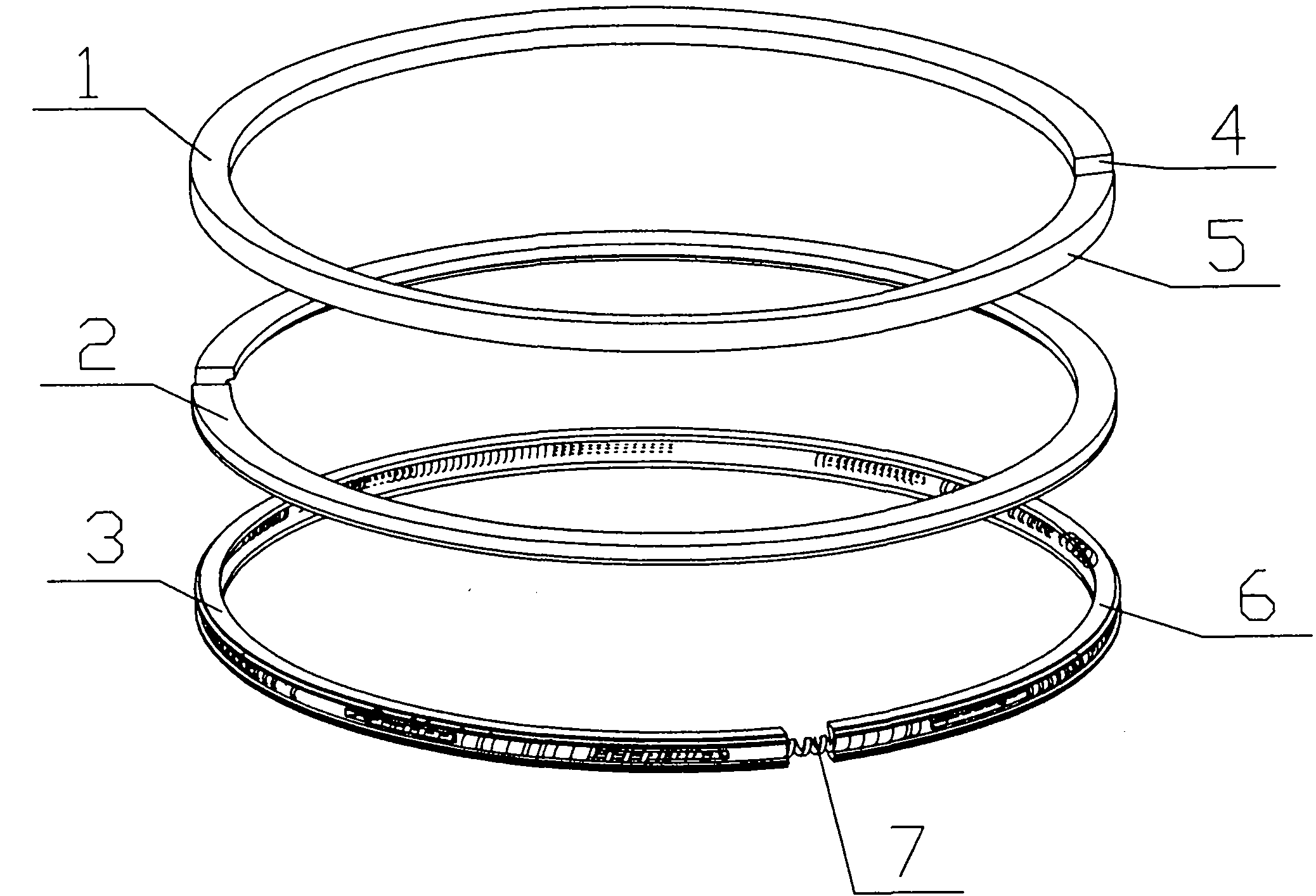

[0026] See attached Figure 1-4 , This embodiment is a ¢93mm piston ring, including the first gas ring 1, the second gas ring 2, and the oil ring fitting 3, wherein the oil ring fitting 3 is composed of the oil ring body 6 and the spring 7. The three piston rings are assembled in the piston ring groove in parallel. The opening angle between the first air ring 1 and the second air ring 2 is 180°. When the oil ring assembly is installed, the angle between the oil ring body and the opening of the spring is 180°. In case the openings overlap, the mixed gas will flow into the crankcase from the openings, which will affect the power of the engine and the quality of the lubricating oil. The first gas ring adopts a trapezoidal semi-inlaid partial barrel surface structure. The cross section 4 of the ring is trapezoidal, and 5 parts of the outer circular surface are inlaid with ceramic particles of 2 to 4 microns; the second gas ring adopts an anti-twisted conical ring structure. The r...

Embodiment 2

[0031] The opening angle between the first gas ring 1 and the second gas ring 2 is 120°, the outer circular surface 5 of the first gas ring is inlaid with 2-6 micron ceramic particles, and the other structures are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com