Metal oxide thin film transistor with top gate structure and manufacturing method thereof

A technology of oxide thin film and oxide film layer, which is applied in the direction of transistors, semiconductor devices, electrical components, etc., can solve the problems of insufficient device characteristics, uniformity and stability, improve the annealing process and environment, and increase electron mobility , to reduce the effect of charge defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Sputtering 20nm oxygen-deficient IGZO (made in a single-component Ar atmosphere) on the alkali-free glass, and then sputtering 5nm oxygen-enriched IGZO (made in a single-component oxygen atmosphere) with the same target; then wet etching Eclipse, graphical IGZO;

[0042] (2) Anneal in a dry oxygen atmosphere at 300°C for one hour;

[0043] (3) Sputtering 20nm silicon dioxide and 300nm silicon nitride on the composite active layer as the insulating layer;

[0044] (4) Anneal in air at 200°C for one hour;

[0045] (5) Sputtering 100nm metal molybdenum as the gate electrode;

[0046] (6) Sputtering 100nm metal molybdenum as source / drain electrodes.

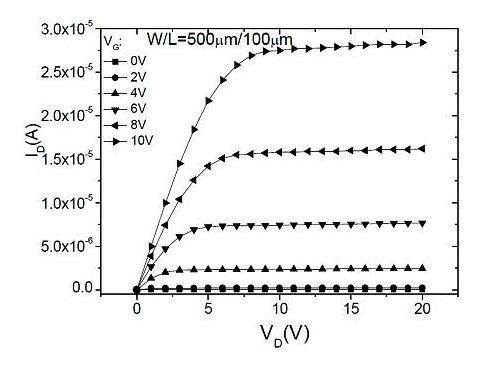

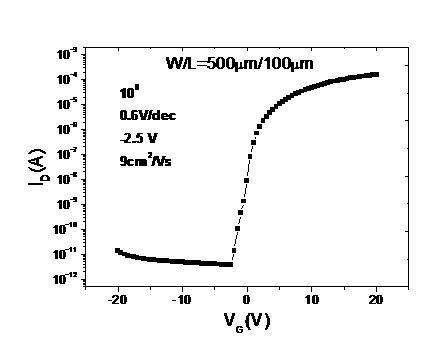

[0047] In addition, in this embodiment 1, please refer to the output characteristic curve figure 2 , please refer to the transfer characteristic curve image 3 .

Embodiment 2

[0049] In this implementation, a thin film transistor was fabricated according to a method and conditions similar to those of Example 1. The difference is that the following two steps are added between (5) and (6):

[0050] (6) Sputtering 5nm metal aluminum for metallizing the active layer;

[0051] (7) Anneal in a dry oxygen atmosphere at 300°C for one hour.

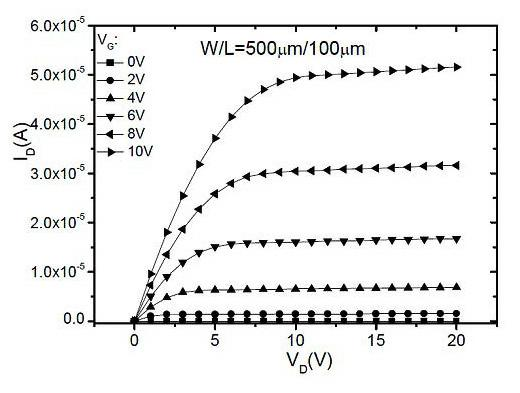

[0052] In addition, in this Example 2, please refer to the output characteristic curve Figure 4 , please refer to the transfer characteristic curve Figure 5 .

Embodiment 3

[0054] In this example, a thin film transistor was fabricated according to a method and conditions similar to those of Example 2. The difference is that the insulating layer annealing in step (4) is cancelled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com