Alpha-hydroxy acid deracemisation method and strain

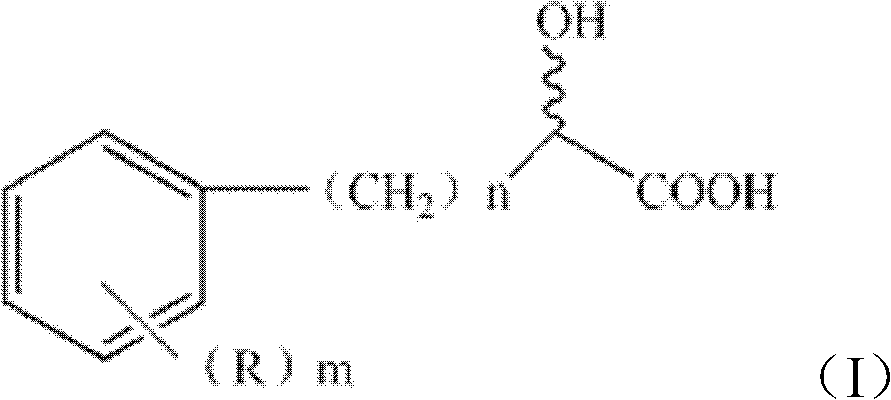

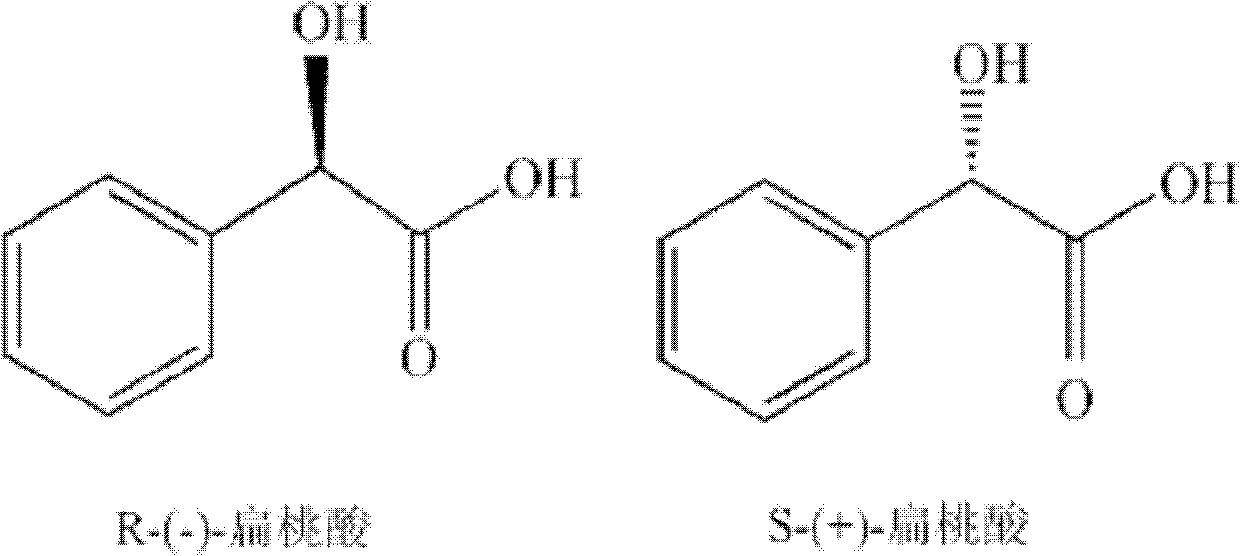

The technology of hydroxy acid and hydroxy acid dehydrogenase is applied in the field of double bacteria coupling catalysis of racemic α-hydroxy acid to produce chiral α-hydroxy acid, which can solve the problems of high cost, small processing capacity, high price and the like, To achieve the effect of less environmental pollution, mild reaction conditions, and reduction of extraction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the fermentation culture of Pseudomonas aeruginosa CCTCC M 2011394

[0036] Fermentation medium: mannitol 10g / L, yeast extract powder 10g / L, K 2 HPO 4 2.5g / L, KH 2 PO 4 2.5g / L, CuCl 2 0.01g / L, NaCl 1g / L, inducer o-chloromandelic acid 2.5g / L, prepared with tap water, pH 7.0, sterilized at 121°C for 20min. After sterilization, cool down and inoculate. Fill a 250mL Erlenmeyer shaker flask with 20% liquid, inoculate a ring of Pseudomonas aeruginosa CCTCC M 2011394, culture at 30°C and 150rpm for 48 hours, centrifuge the fermentation broth and wash twice with normal saline, and collect wet cells after centrifugation ,spare.

Embodiment 2

[0037] Embodiment 2: the fermentation culture of Sinorhizobium CCTCC No: M 2011391

[0038] Fermentation medium: glucose 10g / L, yeast extract 10g / L, K 2 HPO 4 2.5g / L, KH 2 PO 4 2.5g / L, MgSO 4 0.2g / L, FeSO 4 0.03g / L, NaCl 1g / L, inducer mandelic acid 2g / L, prepared in tap water, pH 7.0, sterilized at 121°C for 20min. After sterilization, cool down and inoculate. In a 250mL Erlenmeyer shaker flask with 20% liquid, inoculate a ring of Sinorhizobium CCTCC No: M 2011391, culture at 30°C, 150rpm for 48 hours, centrifuge the fermentation broth and wash twice with normal saline, and collect the wet cells after centrifugation ,spare.

Embodiment 3

[0039] Example 3: Fermentation of Saccharomyces cerevisiae CCTCC No: M 2011393

[0040] Fermentation medium: glucose 20g / L, yeast extract 15g / L, K2HPO4 2.5g / L, KH2PO4 2.5g / L, MgSO 4 0.2g / L, FeSO4 0.03g / L, NaCl 1g / L, prepared with tap water, adjusted pH to 7.0. 250mL Erlenmeyer shaker flask with 20% liquid volume, inoculated with a ring of Saccharomyces cerevisiae CCTCC No: M 2011393, 30°C, 150rpm culture Two days later, the fermented broth was centrifuged and washed twice with physiological saline after the culture was completed, and the wet bacterial cells were collected after centrifugation for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com