A kind of preparation method and application of polymer microsphere

A technology of polymer microspheres and base spheres, applied in ion exchange, ion exchange regeneration, ion exchange treatment devices, etc., can solve the problems of weak retention capacity, unsuitable for large-scale preparation and separation of fullerenes, etc., and achieve high crosslinking degree , easy to control and repeat, and improve the effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

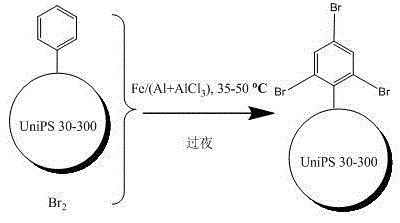

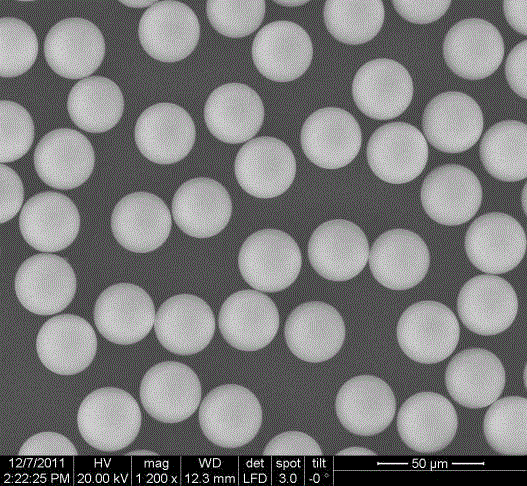

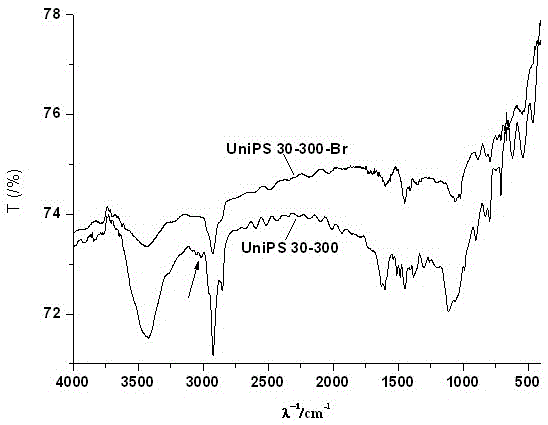

[0022] According to the technical scheme disclosed in Chinese invention patent CN101186661, polystyrene microspheres are prepared, which are denoted as UniPS30-300. Weigh 40.00g of polystyrene microspheres (UniPS30-300 microspheres, about 30μm in diameter) as the base ball and 2.00g of iron powder in a dry 500mL three-necked bottle, and then fill the three-necked bottle in turn Stirrer, serpentine condenser and constant pressure funnel, the upper port of the serpentine condenser is connected to the tail gas absorption device, and the absorption liquid is sodium bisulfite solution. First add 300mL of dichloroethane solvent into the three-necked flask, and stir the microspheres evenly, then slowly drop 50mL of bromine into the above suspension solution, the dropwise addition is completed in about 30 minutes, and the three-necked flask is immersed in an ice bath to prevent reaction too violent. During the reaction process of the three-necked bottle, attention should be paid to a...

Embodiment 2

[0028] The reaction device and tail gas absorption are the same as in Embodiment 1. 10.00 g of polystyrene UniPS30-300 microspheres, 0.75 g of anhydrous aluminum chloride and 0.40 g of aluminum powder were weighed in advance in a dry 250 mL three-necked bottle. Add 75mL of carbon tetrachloride solvent to the three-necked flask, and stir the UniPS30-300 microspheres evenly. Finally, 25 mL of bromine chloride was slowly added dropwise to the suspension solution, and the dropwise addition was completed in about 30 minutes. Reaction control and ball washing steps are the same as in Example 1. 20.60 g of dry polymer microspheres were obtained, and the bromine content was 51.46%.

Embodiment 3

[0030] The reaction device and tail gas absorption are the same as in Example 1. In a dry 250mL there-necked bottle, weigh 10.00g of polystyrene UniPS30-300 microspheres, 0.40g of anhydrous aluminum chloride, 0.20g of aluminum powder and 0.50g of anhydrous Phosphorus pentoxide. First add 50mL of chloroform solvent into the three-necked flask, and stir the microspheres evenly. Slowly add 50 mL of bromine to the above suspension solution dropwise, and the dropwise addition is completed in about 30 minutes. Slowly raise the temperature to 35° C. to ensure a stable reaction, and react overnight. The ball washing step is also the same as in Example 1. 21.35 g of dry polymer microspheres were obtained, and the bromine content was 53.16%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com