Metal wire mesh reinforced heat-conducting plastic with high strength, high corrosion resistance and high heat conductivity

A heat-conducting plastic and wire mesh technology, applied in metal layered products, layered products, synthetic resin layered products, etc., to achieve the effect of high thermal conductivity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

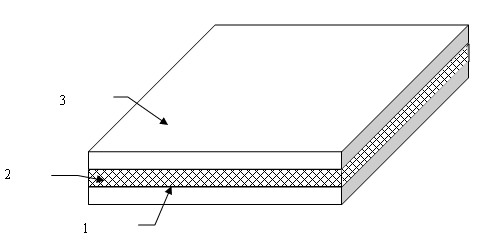

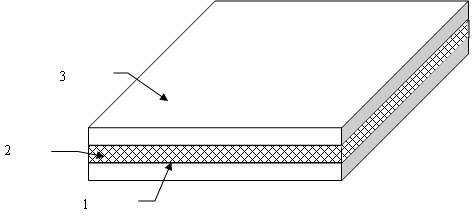

[0023] By weight, 95 parts of polyethylene, 5 parts of polyethylene grafted maleic anhydride, 1 part of ethylene-vinyl acetate copolymer, 200 parts of thermally conductive filler flake graphite, 5 parts of titanate coupling agent, and 10 parts of polyethylene wax The parts are mixed with a high-speed mixer, and then extruded and granulated with a twin-screw extruder. First use the method of co-extrusion to prepare a sheet or plate whose lower layer is a thermally conductive plastic layer, the core layer is a reinforced layer formed by conductive plastic and a layer of stainless steel mesh, and the upper layer is a thermally conductive plastic layer. Cool to set. The thickness of the lower layer of thermally conductive plastic is 0.1mm, and the thickness of the stainless steel mesh reinforcement layer is 0.1mm; the thickness of the upper layer of thermally conductive plastic is 0.6mm. The mesh number of this stainless steel is 50 orders, and the diameter of steel wire is 0.1 m...

Embodiment 2

[0025] By weight, 100 parts of polyethylene, 10 parts of polyethylene grafted maleic anhydride, 10 parts of ethylene-vinyl acetate copolymer, 100 parts of thermal conductive filler flake graphite, 5 parts of aluminate coupling agent, 10 parts of polyethylene wax The parts are mixed with a high-speed mixer, and then extruded and granulated with a twin-screw extruder. First use the method of co-extrusion to prepare a sheet or plate with the lower layer as the thermally conductive plastic layer, the core layer as the reinforcement layer formed by conductive plastic and two layers of wire mesh, and the upper layer as the thermally conductive plastic layer, and then cut and heat press in the mold and cooling molding. The thickness of the lower layer of thermally conductive plastic is 0.2 mm, and the thickness of the wire mesh reinforcement layer is 0.2 mm; the thickness of the upper layer of thermally conductive plastic is 0.5 mm. The mesh number of the stainless steel is 800 mesh...

Embodiment 3

[0027] By weight, 100 parts of homopolypropylene (extrusion grade), 5 parts of ethylene-octene copolymer, 30 parts of maleic anhydride grafted polypropylene, 50 parts of thermally conductive filler expanded graphite, and titanate coupling agent 2 The parts are mixed with a high-speed mixer, and then extruded and granulated with a twin-screw extruder. First use the method of co-extrusion to prepare a sheet or plate whose lower layer is a thermally conductive plastic layer, the core layer is a reinforced layer formed by conductive plastic and four-layer copper mesh, and the upper layer is a thermally conductive plastic layer. Cool and shape. The thickness of the lower layer of thermally conductive plastic is 0.1 mm, and the copper mesh reinforcement layer is about 0.5 mm; the thickness of the upper layer of thermally conductive plastic is 0.1 mm. The mesh number of this copper is 800 meshes, and the diameter of copper wire is 0.1 millimeter. The copper mesh reinforced thermall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com