Cyanogen-free Au-Sn alloy electroplating liquid

An alloy electroplating solution, au-sn technology, applied in the field of electroplating, can solve the problems of low current density, low peak current density, slow Sn alloy plating speed, etc., and achieve the effect of smooth coating, good bonding force and increased plating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

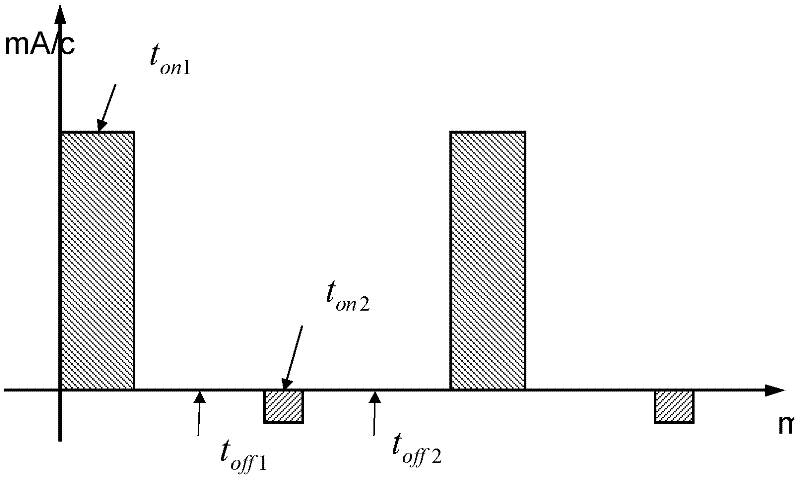

[0048] Electroplating Au-30at.%Sn eutectic coating with reversing pulse, variable amplitude pulse and plating solution of the present invention

[0049] (1) Preparation of Au-Sn alloy electroplating solution

[0050] 1. The composition and content of the plating solution are as follows:

[0051]

[0052] During the electroplating process, the temperature of the plating solution is 45°C, and a pure gold anode is used.

[0053] 2. The preparation steps are as follows:

[0054] 1) To prepare 100ml of gold-tin alloy electroplating solution. Take 40ml of deionized water in a beaker, add 0.012mol of potassium pyrophosphate, 0.001mol of stannous sulfate, 1.5g of hydroquinone, 3g of disodium hydrogen phosphate and 0.05g of cobalt sulfate into the beaker in sequence, and stir evenly.

[0055] 2) Take 40ml of deionized water in a beaker, add 0.048mol of ammonium sulfite, 0.009mol of HEDP, and 0.002mol of monobasic sodium gold sulfite to the beaker in turn, and stir evenly.

[005...

Embodiment 2

[0071] Direct electroplating of Au-30at.% Sn eutectic coating with reversing pulse, variable amplitude pulse, and the composition of the plating solution of the present invention, the composition and parameters of the plating solution:

[0072]

[0073] During the electroplating process, the temperature of the plating solution is 55°C, and platinum and titanium mesh anodes are used for electroplating.

[0074] Plating solution preparation steps are the same as in Example 1.

[0075] The relationship between the composition of the coating and the current density, the surface morphology, thickness and crystal structure of the coating are the same as in Example 1.

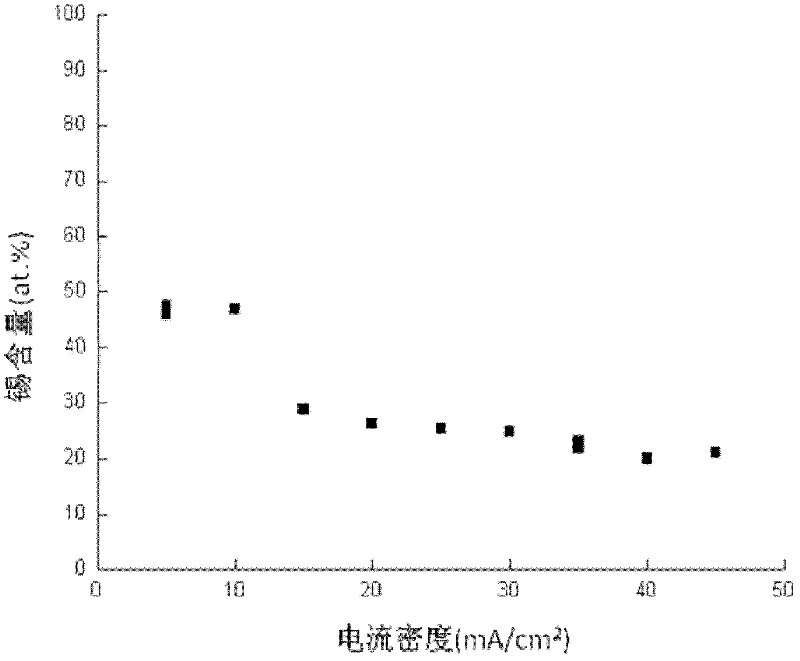

[0076] Measured when the peak current density is lower than 15mA / cm 2 When the tin content of the obtained coating is about 50at.%, it is AuSn phase; when the current density is higher than 35mA / cm 2 When the tin content of the coating is close to 16.5at.%, it is Au 5 Sn phase; when the current density is 23mA / c...

Embodiment 3

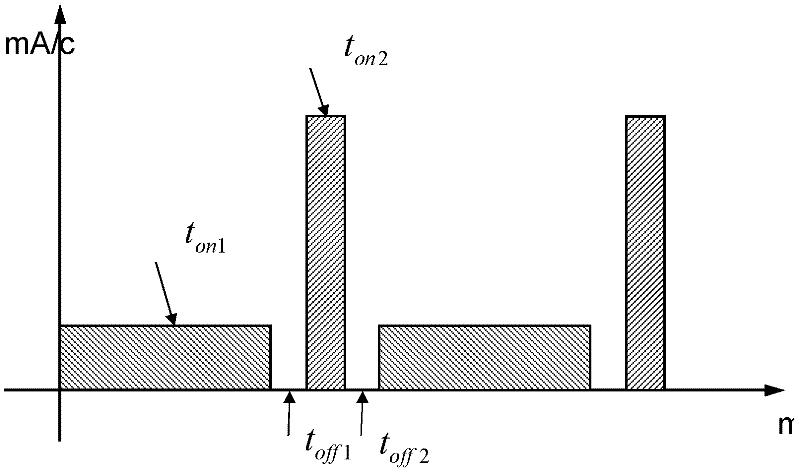

[0083] Au-Sn alloy coatings (Au-30at.%Sn eutectic, Au-25at.%Sn) with different tin contents are prepared by using positive variable amplitude pulse current and plating solution of the present invention

[0084] Bath composition and parameters:

[0085]

[0086] During the electroplating process, the temperature of the plating solution is 25°C, and the electroplating uses stainless steel anodes.

[0087] Plating solution preparation steps are the same as in Example 1.

[0088] The relationship between the composition of the coating and the current density, the surface morphology, thickness and crystal structure of the coating are the same as in Example 1.

[0089] Measured when the peak current density is lower than 6.5mA / cm 2 When the tin content of the obtained coating is about 50at.%, it is AuSn phase; when the current density is higher than 22mA / cm 2 When the tin content of the coating is close to 15at.%, it is Au 5 Sn phase; when the current density is 16mA / cm 2 Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com