Synthesis technique of {001}-surface-exposed visible light titanium dioxide nanosheet with oxygen vacancy

A technology of titanium dioxide and synthesis process, which is applied in the field of synthesis process of visible light titanium dioxide nanosheets, which can solve the problems of limiting the application of photocatalysts and complicated processes, and achieve the effects of simple preparation process, good crystallinity, and strong controllability of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve butyl titanate and titanium tetrafluoride with a molar ratio of 1:2 in a mixed solution of 1.25mL 20wt% nitric acid aqueous solution and 25mL ethanol, age at 40°C for 48h to form a gel, and then put it into a In a supercritical reactor with 250mL of ethanol, age at 10MPa and 260°C for 2h for extraction, and finally collect the sample directly after the extraction cools down.

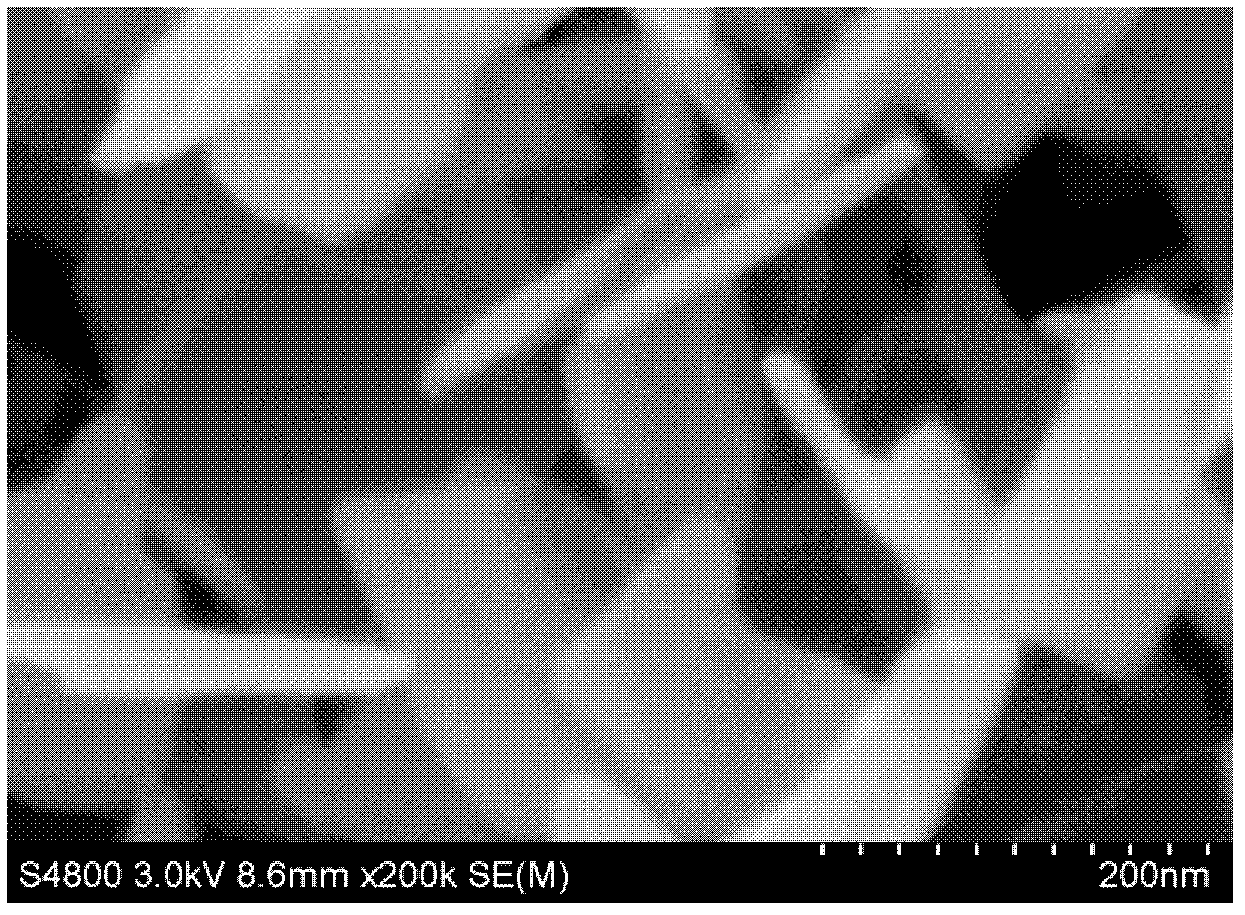

[0023] figure 1 This is the FESEM spectrum of the morphology of visible light titanium dioxide nanosheets with oxygen defects exposed on the {001} plane obtained in this example. It can be seen from the figure that the sample is a single crystal nanosheet.

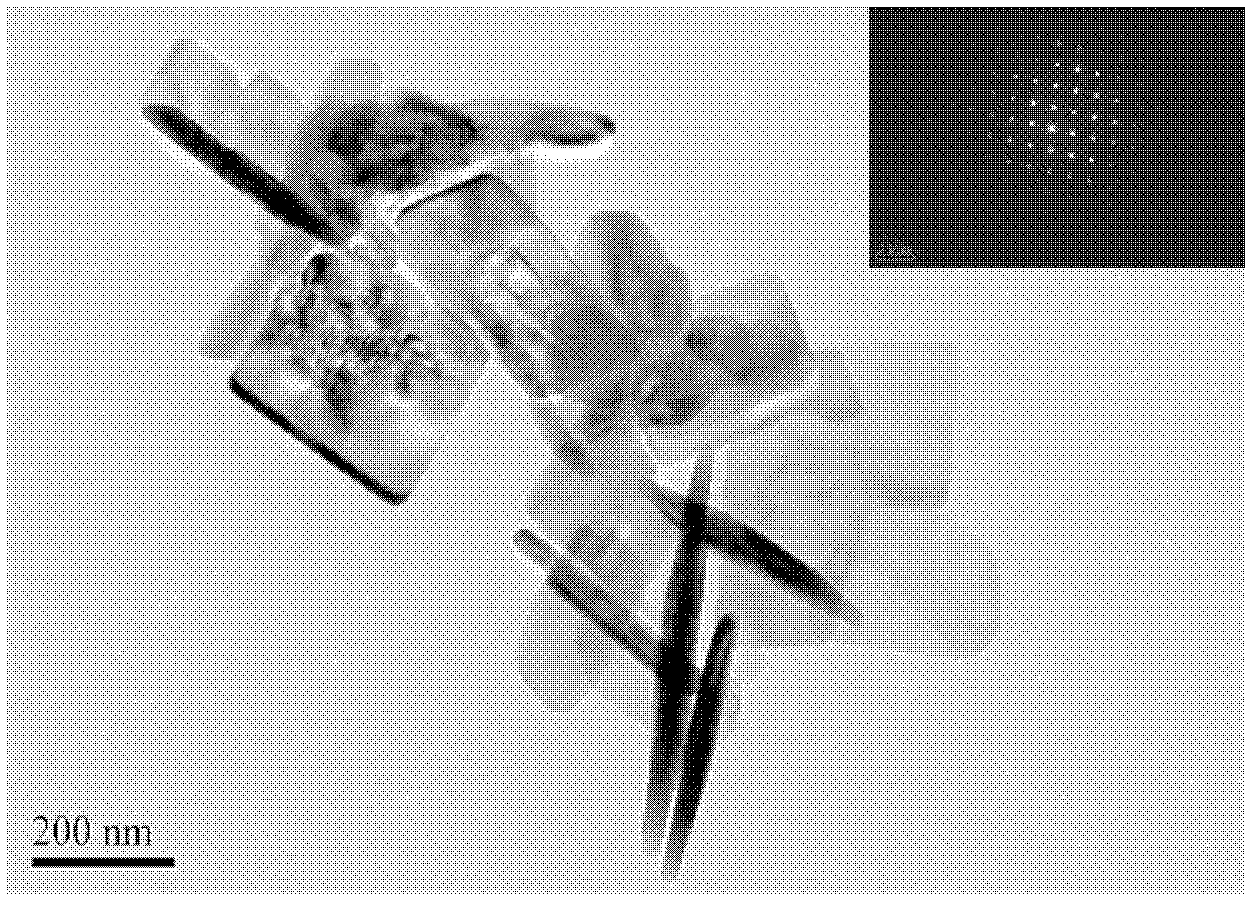

[0024] figure 2 This is the TEM image of visible light titania nanosheets with oxygen defects exposed on the {001} surface obtained in this example. The size is about 200 nm and the thickness is about 10 nm. The electron diffraction of the sample shows that it has a single crystal structure.

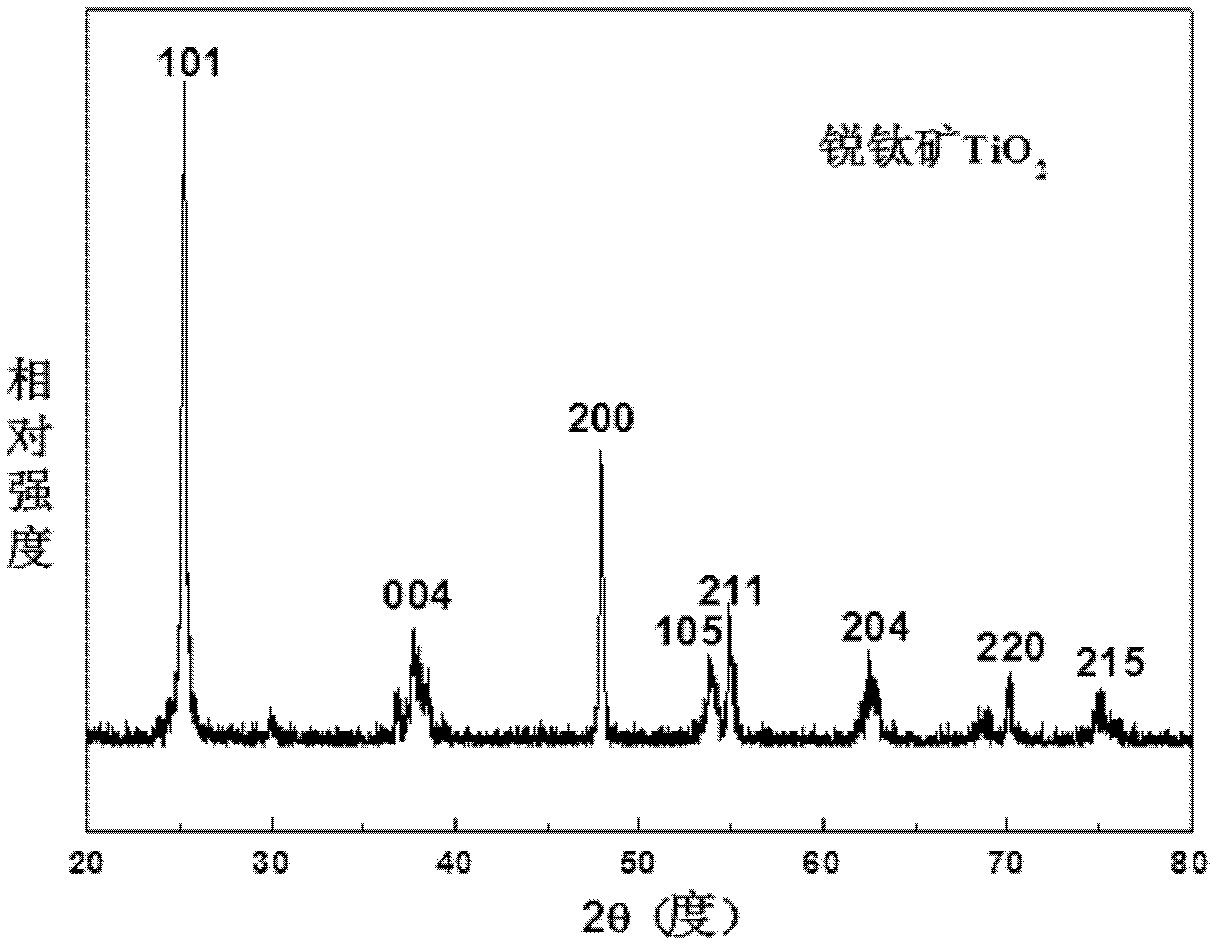

[0025] image 3 The XRD pattern of vi...

Embodiment 2

[0028] The operation steps of Example 1 were repeated, except that in a supercritical reactor, aging was carried out at 270° C. for 2 h for extraction. The result was similar to that of Example 1, but the nanosheets became larger and thinner. The microstructure of the sample is consistent with that of Example 1, the crystallinity is consistent with that of Example 1, and the diffuse reflectance results show that the sample has a visible light response.

Embodiment 3

[0030] The operation steps of Example 1 were repeated, except that in a supercritical reactor, aging was carried out at 280° C. for 2 h for extraction. The result was similar to that of Example 1, but the nanosheets became relatively larger and thinner. The microstructure of the sample is consistent with that of Example 1, the crystallinity is consistent with that of Example 1, and the diffuse reflectance results show that the sample has a visible light response.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com