MgZnO/N-propyl bromide (NPB) ultraviolet light detector and producing method thereof

A detector and ultraviolet light technology, applied in the field of optoelectronic information, can solve the problems of low organic electron mobility, p-type doping of inorganic wide bandgap semiconductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

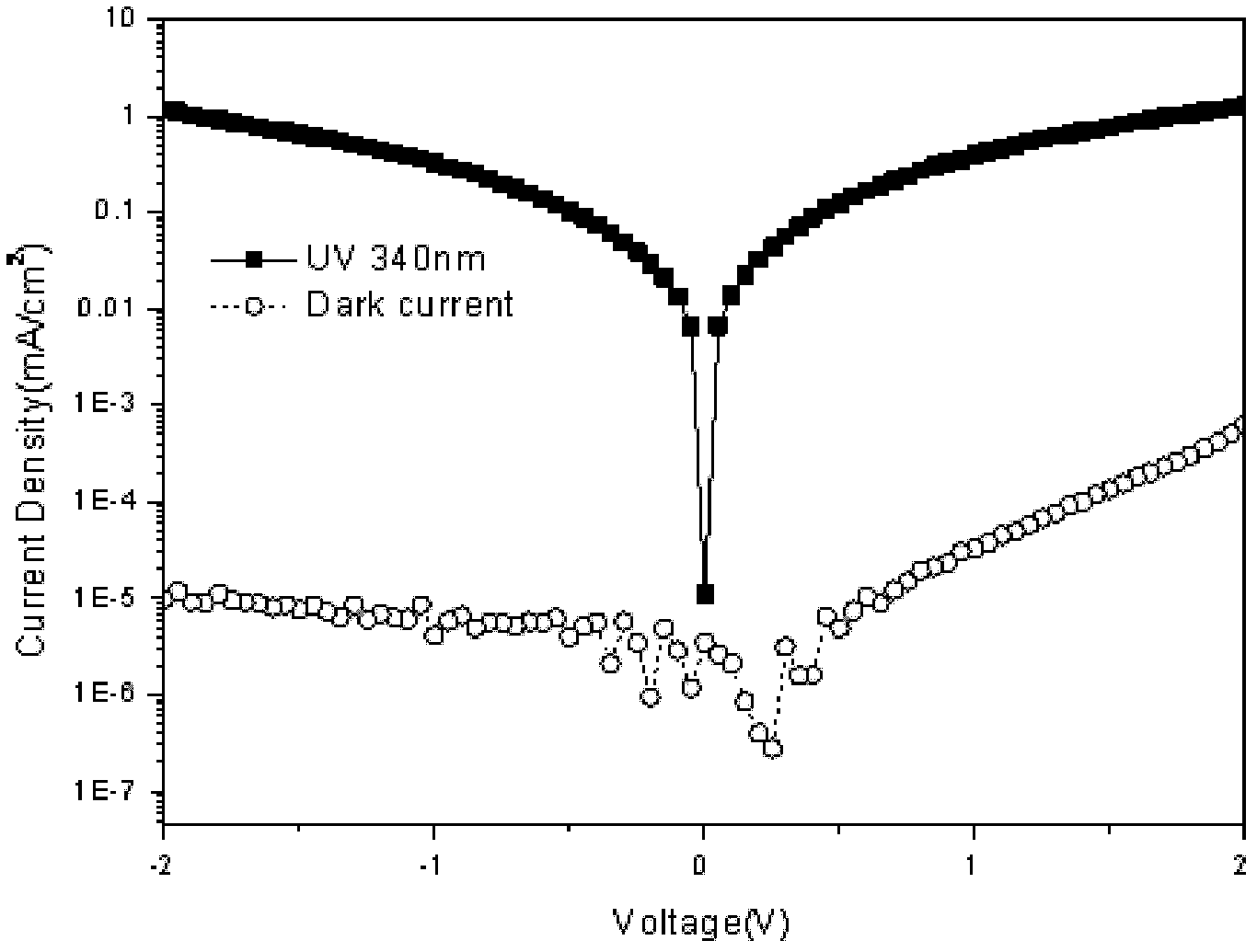

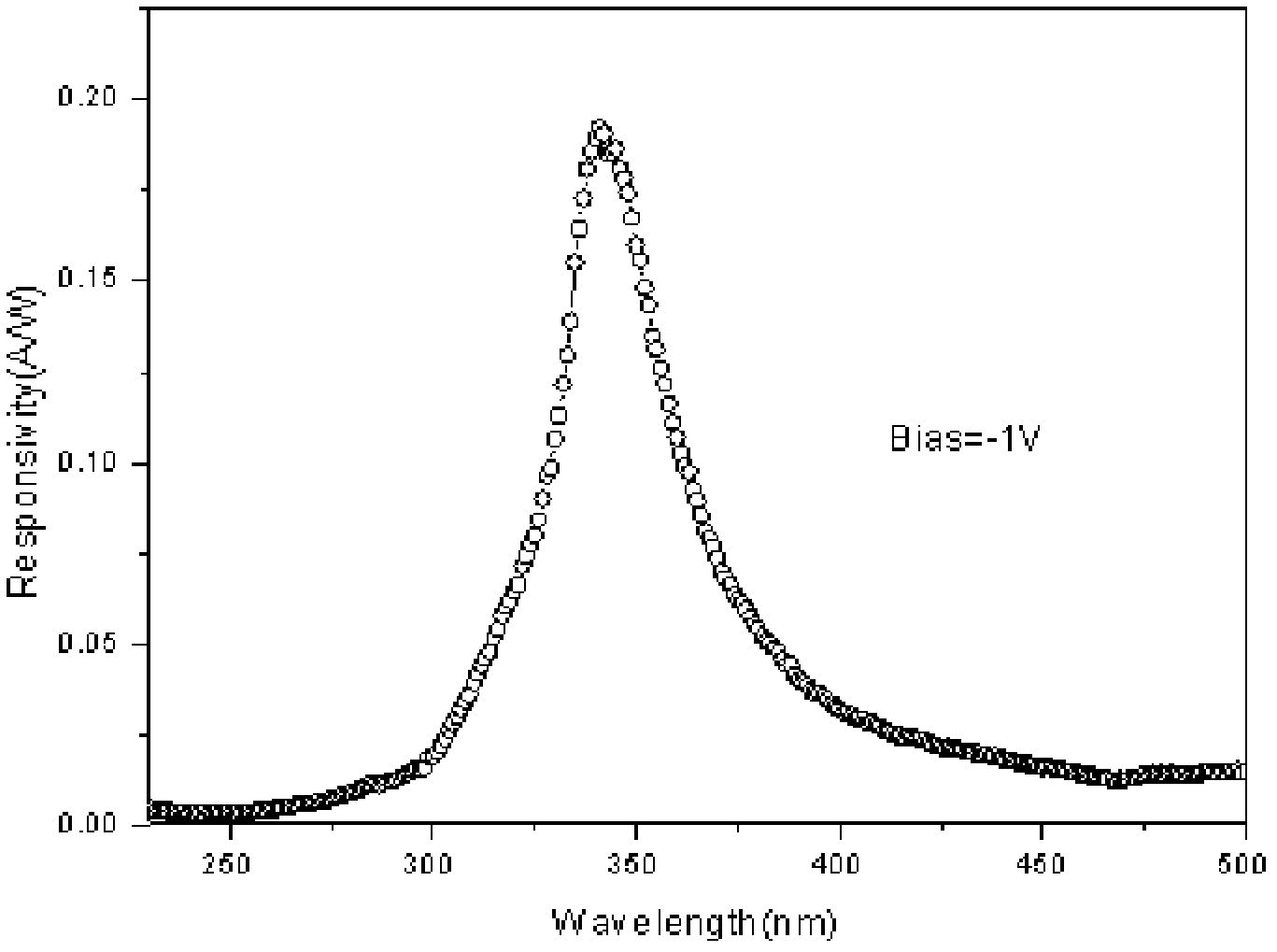

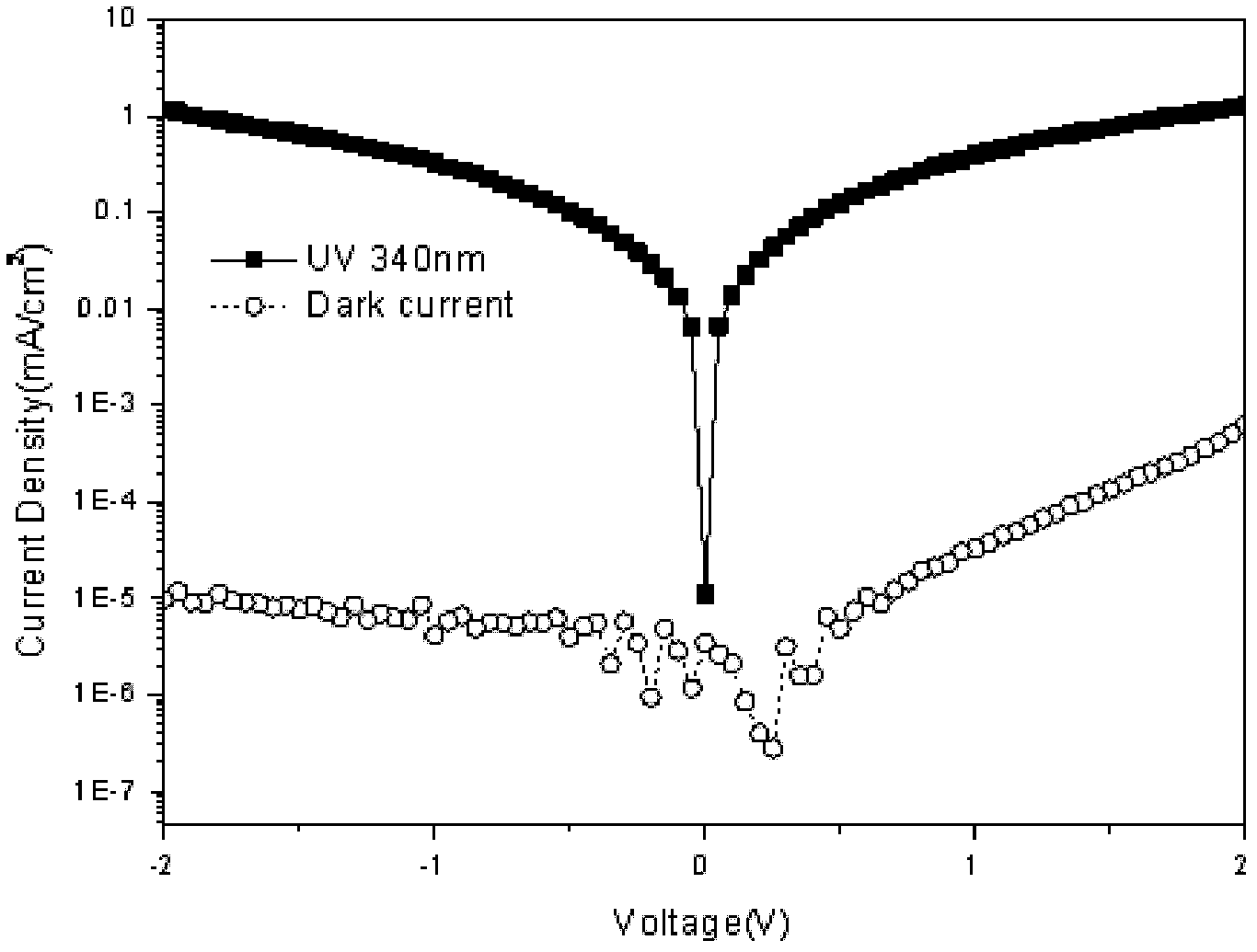

[0018] A MgZnO / NPB ultraviolet light detector, the ultraviolet light detector is a single-phase Mg grown on a quartz ITO substrate x Zn 1-x O thin film, NPB thin film, LiF thin film and electrode. The single-phase Mg x Zn 1-x In O, X=0.1-0.4, and the thickness is 200-350nm; the thickness of the NPB film is 50-120nm; the thickness of the LiF film is 0.5-2nm.

[0019] A kind of MgZnO / NPB ultraviolet photodetector manufacture method one, the step of this method comprises:

[0020] Step 1 imports the cleaned quartz ITO substrate into the pre-growth chamber of MBE;

[0021] Step 2: Treat in the pre-growth chamber at 750°C for 30 minutes;

[0022] Step 3. The quartz ITO substrate processed in step 2 is introduced into the growth chamber of MBE, and at a growth temperature of 400°C, Mg with a thickness of 200nm is grown. x Zn 1-x O film, where X=0.1;

[0023] Step 4 will Mg x Zn 1-x The O thin film is introduced into the thermal evaporation, and the Mg x Zn 1-x On the O f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com