Preparation method of copper and copper alloy oval tube

A copper alloy and elliptical tube technology is applied in the field of preparation of copper and copper alloy elliptical tubes to achieve the effect of reducing production costs and saving non-ferrous metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

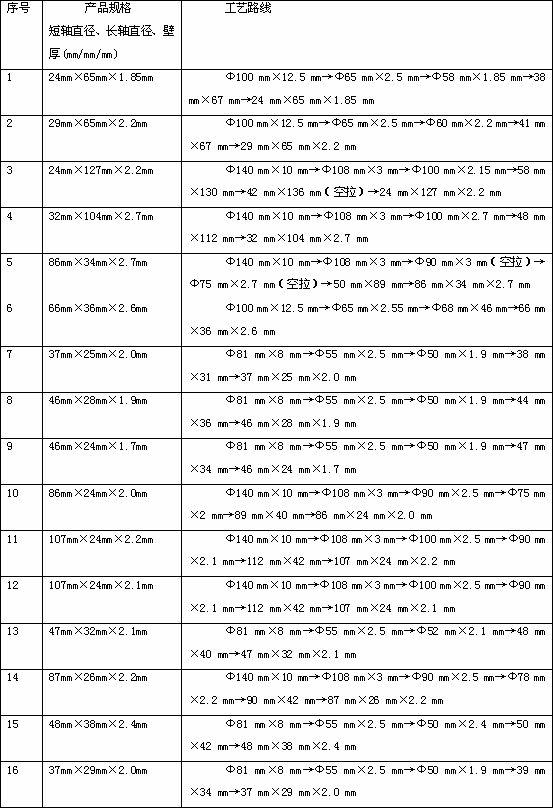

[0014] The production technology of oval tube of the present invention is as follows:

[0015] ⑴Smelting and casting of T2 red copper ingots: using standard cathode copper as raw material, using industrial frequency induction furnace for melting, adopting vertical semi-continuous casting process or horizontal continuous casting process to produce T2Φ260mm, T2Φ310mm ingot melting process using calcined charcoal as cover As a deoxidizer, a trace amount of Mg or Mn compounded with a trace rare earth (Ce or CeO) can be added as a deoxidizer (the deoxidation effect of titanium or phosphorus is good, but it has a great influence on the conductivity). Under the protection of gas or nitrogen, the melt transfer and casting operations can also be covered with carbon powder to obtain T2Φ260mm and T2Φ310mm ingots. Perform surface quality inspection on the ingot, and cut to length on the automatic sawing unit to obtain short extruded ingots of T2Φ260 mm×520mm or T2Φ310 mm×600mm.

[0016] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com