Curing process method for radioactive nuclide polluted sandy soil

A technology of radionuclide and solidification treatment, applied in the field of radioactive waste treatment, can solve the problems of unsuitable large-scale engineering application, unrealistic, small processing capacity, etc., to improve stability, increase glass phase content, increase resistance Effect of Alteration Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

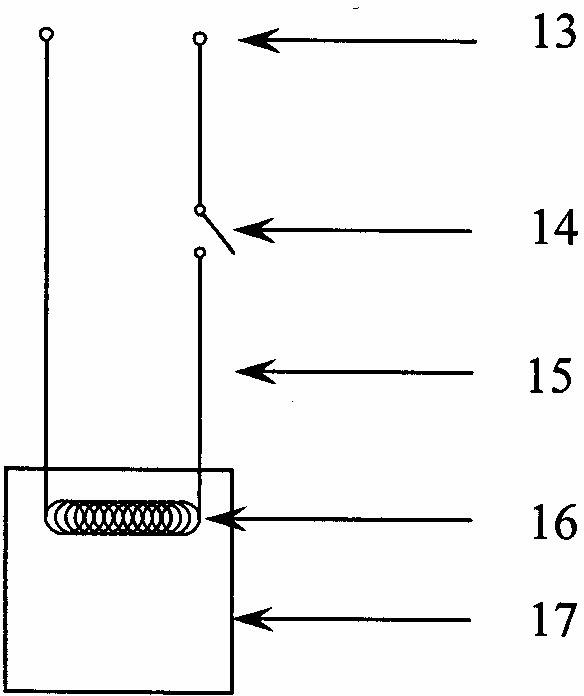

[0032] Aluminum powder, iron oxide powder, CaO 2 , SiCa is weighed according to the mass ratio of 0.5: 1.5: 0.03: 0.04, placed in the mixer in turn, stirred at 60 rpm for 40 minutes at room temperature and pressure, and mixed evenly; then mixed with sand, TiO 2 and three simulated radionuclides SrO, Er 2 o 3 , CeO 2 Weigh it according to the mass ratio of 2.07:1:0.01:0.01:0.01:0.01, put it in the mixer in turn, and stir it at 45 rpm for 90 minutes at room temperature and pressure, and mix evenly; In a cement pool with a height of 2m and a height of 2m, install an electric ignition device, fill 35cm of dry sand around the pool, cover the top with 80cm of dry sand, and then install a cover plate; after the ignition reaction, take the solidified body for analysis. The contents of , erbium and cerium are basically the same as the addition amount, and the 28-day average leaching rate of Ce is 1.9×10 -5 g / (m 2 d), Sr is 2.0×10 -3 g / (m 2 d), Er is 1.8×10 -5 g / (m 2 d).

Embodiment 2

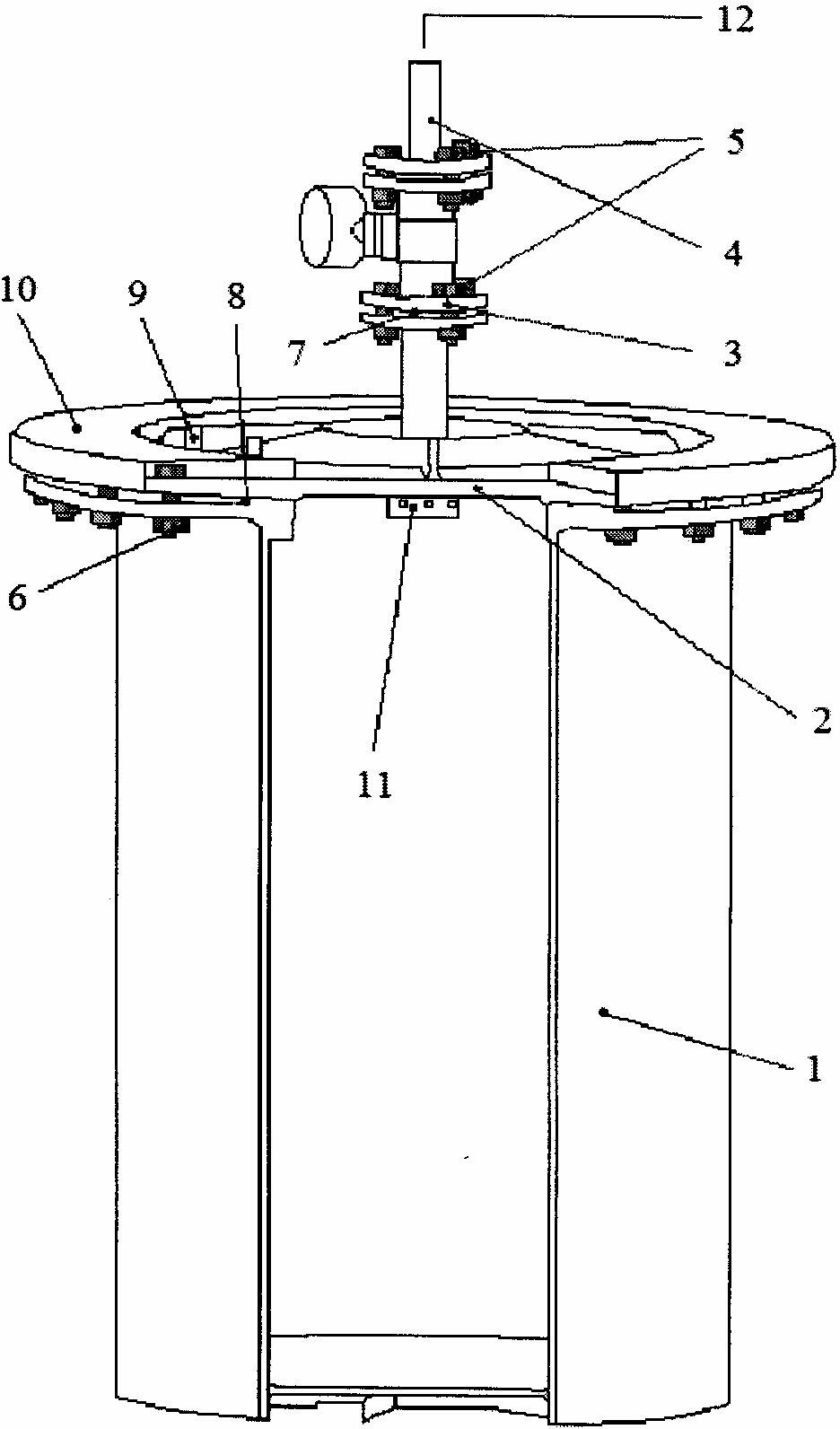

[0034] Aluminum powder, iron oxide powder, KMnO 4 、Na 2 B 4 o 7 10H 2 O was weighed according to the mass ratio of 0.46:1.39:0.14:0.03, placed in the mixer in turn, stirred at 90 rpm for 50 minutes at room temperature and pressure, and mixed evenly; then mixed with sand, ZrO 2 , Y 2 o 3 , CeO 2Weigh it according to the mass ratio of 2.02:1:0.01:0.01:0.03, put it in the mixer in turn, stir at 60 rpm for 100 minutes at room temperature and pressure, and mix evenly; In a self-made cylindrical steel container with a height of 1m, install an electric ignition device, fill the surrounding area with 25cm of dry sand, cover the top with 78cm of dry sand, and then install a cover plate; after the ignition reaction, take the solidified body for analysis, and get , the 28-day average leaching rate of the simulated radionuclide Ce was 1.0–1.8×10 -5 g / (m 2 d).

Embodiment 3

[0036] Aluminum powder, iron oxide powder, CrO 3 、MoO 3 Weigh it according to the mass ratio of 0.53:1.58:0.1:0.1, put it in the mixer in turn, and stir it at 120 rpm for 30 minutes at room temperature and pressure, and mix it evenly; then mix it with sand, TiO 2 , ZrO 2 , CeO 2 Weigh it according to the mass ratio of 2.31: 1: 0.18: 0.14: 0.18, place it in the mixer in turn, stir at 45 rpm for 120 minutes at room temperature and pressure, and mix evenly; In a self-made cylindrical steel container with a height of 1m, install the electric ignition device, fill the surrounding area with 40cm of dry sand, cover the top with 90cm of dry sand, and then install a cover plate; after the ignition reaction, take the solidified body for analysis, and get , the 28-day average leaching rate of the simulated radionuclide Ce was 4.3×10 -6 g / (m 2 d).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com