Polyethylene glycol dendritic polymers and preparation method thereof

A technology based on polyethylene glycol and polyethylene glycol, which is applied in the chemical industry, can solve the problems of limited combined use, waste of package load function, and non-utilization of hydrophobic space, and achieves the effect of mild reaction conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

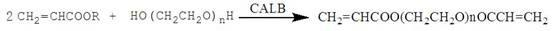

Method used

Image

Examples

Embodiment 1

[0038] Using PEG200, ethyl acrylate (abbreviation: EA) and ethylenediamine as raw materials, methanol as the catalyst and solvent for the addition reaction to prepare PEG dendrimers, the preparation method is as follows:

[0039] (1) Preparation of branch unit: Dissolve 2.00g of PEG200 in 20mL of tetrahydrofuran (abbreviation: THF), add 6.00g of EA, after stirring evenly, add 100mg of Novozyme 435, and react for 48h under stirring at 50°C. After the reaction, filter The enzyme was removed, the filtrate was distilled under reduced pressure to remove the solvent, excess EA and by-product ethanol, the remaining liquid was separated by column chromatography, and the eluent of petroleum ether / ethyl acetate was eluted to obtain the product as PEG200 diacrylate, pale yellow and transparent Liquid, the average molecular weight is 308g / mol;

[0040](2) Preparation of the first generation polyethylene glycol dendrimer (G1): Dissolve 3.08 g of PEG200 diacrylate in 10 mL of methanol, diss...

Embodiment 2

[0050] Using PEG400, methyl acrylate (referred to as: MA) and 1,3-propanediamine (hereinafter referred to as: propylene diamine) as raw materials, potassium tert-butoxide as the catalyst for the addition reaction to prepare PEG dendrimers, the preparation method is as follows :

[0051] (1) Preparation of branch unit: Dissolve 4.00g PEG400 in 25mL THF, add 5.16g MA, stir evenly, add 250mg Novozyme 435, and react at 50°C for 48h under stirring conditions. After the reaction, the enzyme is removed by filtration, and the filtrate is reduced The solvent, excess MA and by-product methanol were removed by pressure distillation, the remaining liquid was separated by column chromatography, and the eluent of petroleum ether / ethyl acetate was eluted to obtain the product PEG400 diacrylate, pale yellow transparent liquid, and the average molecular weight was 508g / mol;

[0052] (2) Preparation of the first generation polyethylene glycol dendrimer (G1): Dissolve 5.08g PEG400 diacrylate in...

Embodiment 3

[0062] Using PEG600, vinyl acrylate (abbreviation: VA) and 1,4-butanediamine (hereinafter referred to as: butanediamine) as raw materials, triethylamine as the catalyst for the addition reaction to prepare PEG dendrimers, the preparation method is as follows:

[0063](1) Preparation of branch unit: Dissolve 6.00g PEG600 in 25mL THF, add 5.88g VA, stir evenly, add 250mg Novozyme 435, and react at 50°C for 48h. The solvent, excess VA and by-product acetaldehyde were distilled off, the remaining liquid was separated by column chromatography, and the eluent of petroleum ether / ethyl acetate was eluted to obtain the product PEG600 diacrylate, pale yellow transparent liquid with an average molecular weight is 708g / mol;

[0064] (2) Preparation of the first generation polyethylene glycol dendrimer (G1): Dissolve 7.08g PEG600 diacrylate in 10mL THF, take 0.088g butanediamine and 0.404g triethylamine and dissolve in 1mL THF, stirring conditions The THF solution of butanediamine was slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com