Method for preparing water surface floating oil scavenging agent

A technology for oil slicks and surface loads on water surfaces, applied in separation methods, chemical instruments and methods, grease/oily substances/suspton removal devices, etc. Limited surface area and other issues, to achieve high stability and reuse rate, improve the adsorption capacity of floating oil, and the effect of large oil pollution adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

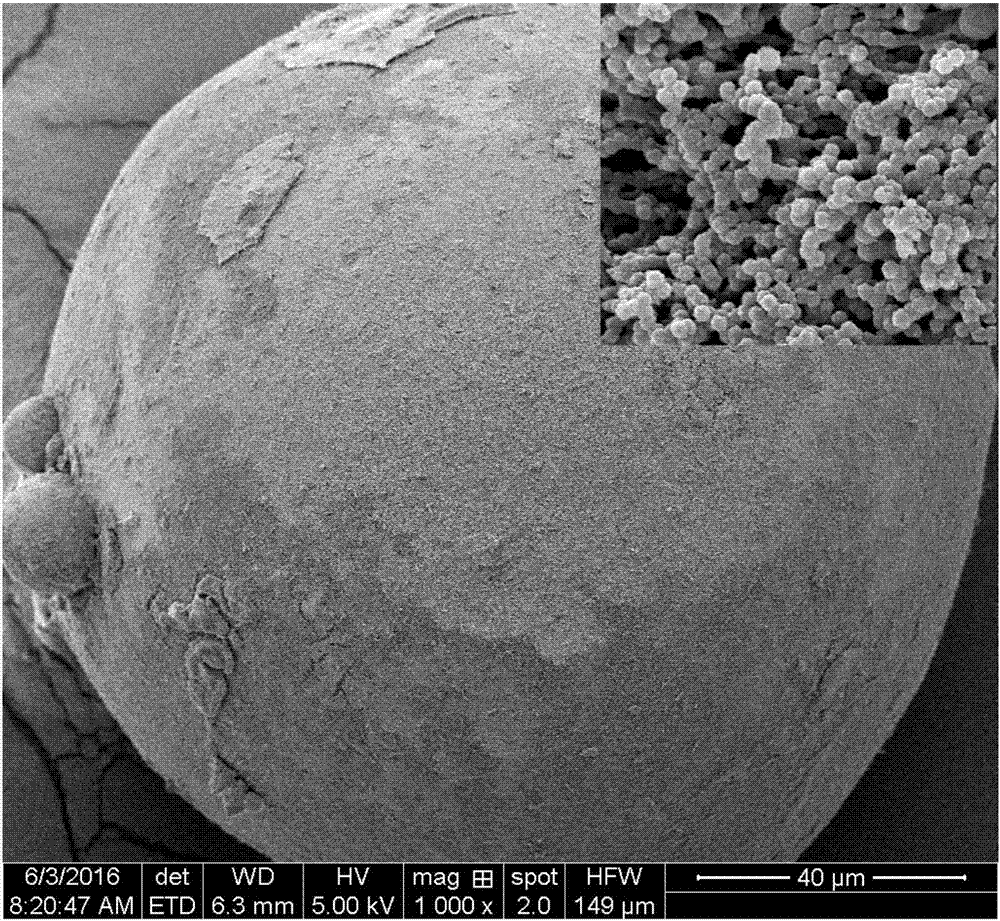

[0029] Taking fly ash as carrier, PSt and KH171 as intermediates to prepare water surface oil slick remover, its preparation method is as follows:

[0030] (1) Disperse 50g of fly ash particles in 500mL of 0.5% vinyltrimethoxysilane (KH171) ethanol solution, fully stir and mix and filter to obtain fly ash particles with KH171 adsorbed on the surface, and dry at 50°C;

[0031] (2) Dilute the polystyrene (PSt) emulsion obtained by copolymerization of styrene (St), methacrylic acid (MAA), and α-olefin sulfonate sodium (AOS) to 5% with water, and add the particles obtained in step (1) , after fully stirring and mixing, let stand, separate, and dry to obtain the fly ash particle Fly-ash / PSt with PSt on the surface;

[0032] (3) Add an appropriate amount of KH171 to the KH171 ethanol solution obtained by filtering in step (1), then add a small amount of water, stir evenly, add the Fly-ash / PSt composite particles obtained in step (2), and mix thoroughly. Dilute 20mL of tetrabutyl ti...

Embodiment 2

[0036] Taking fly ash as carrier, PSt and KH171 as intermediates to prepare water surface oil slick remover, its preparation method is as follows:

[0037] (1) Disperse 50g of fly ash particles in 500mL of 0.5% vinyltrimethoxysilane (KH171) ethanol solution, fully stir and mix and filter to obtain fly ash particles with KH171 adsorbed on the surface, and dry at 50°C;

[0038] (2) Dilute the polystyrene (PSt) emulsion obtained by copolymerization of styrene (St), methacrylic acid (MAA), and α-olefin sulfonate sodium (AOS) to 5% with water, and add the particles obtained in step (1) , after fully stirring and mixing, let stand, separate, and dry to obtain the fly ash particle Fly-ash / PSt with PSt on the surface;

[0039] (3) Add an appropriate amount of KH171 to the KH171 ethanol solution obtained by filtering in step (1), then add a small amount of water, stir evenly, add the Fly-ash / PSt composite particles obtained in step (2), and mix thoroughly. Dilute 20mL of tetrabutyl ti...

Embodiment 3

[0043] With closed-cell perlite as carrier, PSt and KH171 as intermediates to prepare water surface oil slick remover, its preparation method is as follows:

[0044] (1) Disperse 50g of perlite particles in 500mL of 0.5% vinyltrimethoxysilane (KH171) ethanol solution, stir and mix thoroughly, then filter to obtain perlite particles with KH171 adsorbed on the surface, and dry at 50°C;

[0045] (2) Dilute the polystyrene (PSt) emulsion obtained by copolymerization of styrene (St), methacrylic acid (MAA), and α-olefin sulfonate sodium (AOS) to 5% with water, and add the particles obtained in step (1) , after fully stirring and mixing, let stand, separate, and dry to obtain perlite particles Per / PSt with PSt on the surface;

[0046] (3) Add an appropriate amount of KH171 to the KH171 ethanol solution obtained by filtering in step (1), then add a small amount of water, stir evenly, add the Per / PSt composite particles obtained in step (2), and mix thoroughly. Dilute 20mL of tetrabu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com