Polyimide resin as well as preparation method and application thereof

A polyimide resin and reaction technology, applied in the field of polyimide resin and its preparation, can solve the problems of low solid content, difficult molding processing, poor fluidity, etc., and achieve high glass transition temperature and good melt fluidity , the effect of low solution viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

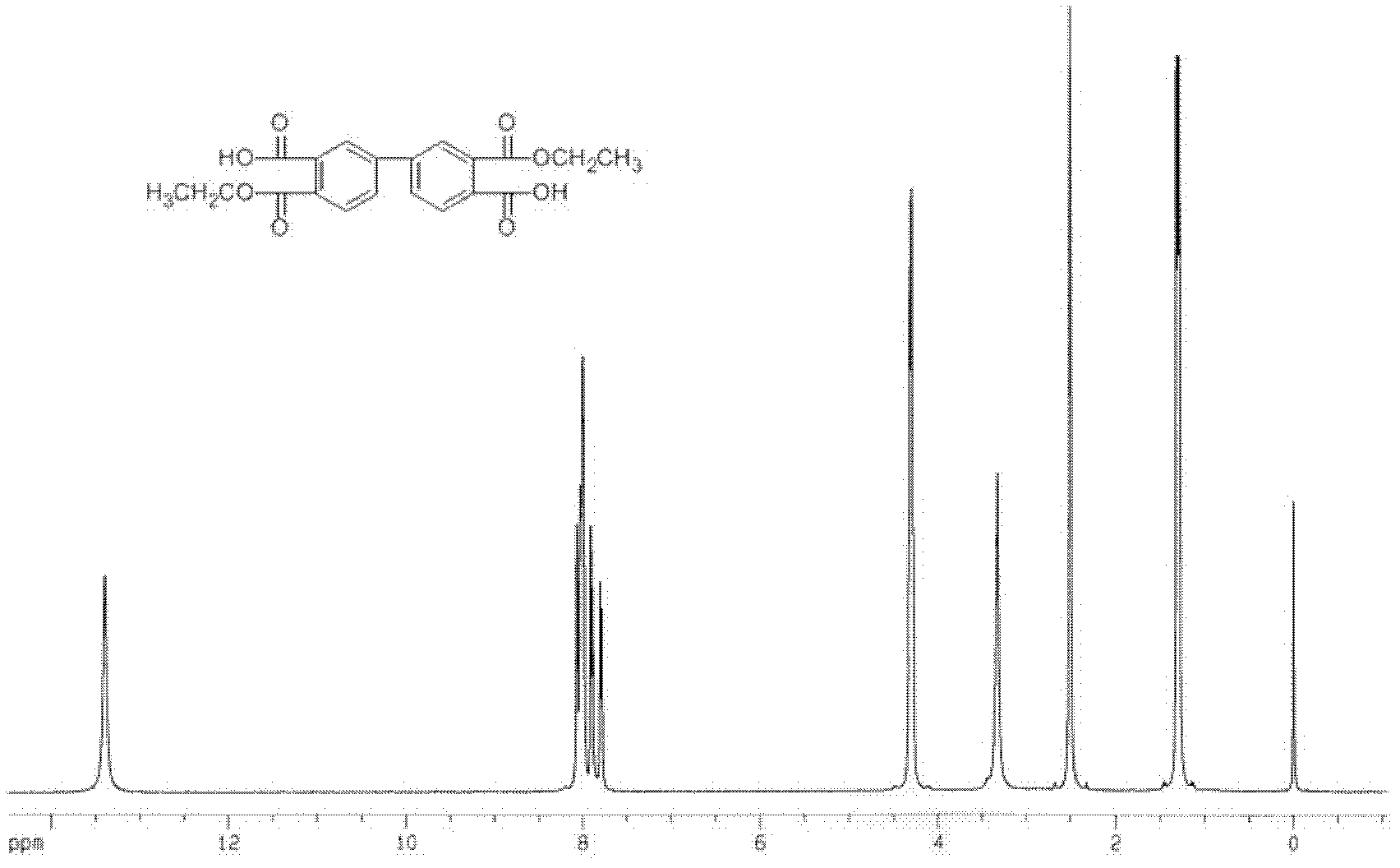

[0035] 1) Add 29.74gs-BPDA (0.1011mol), 35g absolute ethanol, and 7g DMF in a 250ml there-necked flask equipped with a mechanical stirrer, a spherical reflux condenser and a thermometer, and heat to reflux for 6 hours under stirring to obtain light Yellow s-BPDA diacid diethyl ester (s-BPDE) homogeneous solution; attached figure 1 It is the 1HNMR spectrum of s-BPDE. It can be seen that s-BPDA has been esterified to form the corresponding diacid diethyl ester (s-BPDE).

[0036] 2) Add 4.96g (0.02mol) 4-PEPA and 10g of absolute ethanol to a 50ml single-necked bottle equipped with an electromagnetic stirring device and a spherical reflux condenser, and heat, stir and reflux for 2 hours to obtain monoethyl monoformate of 4-PEPA (4-PEPE) homogeneous solution;

[0037] 3) Pour this solution into the solution in step 1), then add 18.90g (0.0944mol) 3,4'-ODA and 4.88g (0.0167mol) 1,3,4-APB, supplement ethanol to the solid content of the solution was 48%, stirred at room temperature ...

Embodiment 2

[0039] 1) Add 29.74gs-BPDA (0.1011mol), 35g of anhydrous methanol, and 7g of DMAc in a 250ml there-necked flask equipped with a mechanical stirrer, a spherical reflux condenser, and a thermometer, and heat to reflux for 4 hours under stirring to obtain light Yellow s-BPDA dioic acid dimethyl ester (s-BPDE) homogeneous solution; 2) Add 4.96g (0.02mol) 4-PEPA, 10g Anhydrous methanol is heated and stirred to reflux for 2 hours to obtain a homogeneous solution of monomethyl monoformate (4-PEPE) of 4-PEPA;

[0040] 3) Pour this solution into the solution in step 1), then add 18.90g (0.0944mol) 3,4'-ODA and 4.88g (0.0167mol) 1,3,4-APB, supplement methanol to the solid content of the solution was 49%, stirred at room temperature for 2 hours to obtain a brown polyimide resin homogeneous solution, and its rotational viscosity at 25° C. was 55-60 mPa.s.

Embodiment 3

[0042] 1) Add 29.74gs-BPDA (0.1011mol), 35g absolute ethanol, and 7g NMP in a 250ml there-necked flask equipped with a mechanical stirrer, a spherical reflux condenser and a thermometer, and heat to reflux for 4.5 hours under stirring to obtain a light Yellow s-BPDA diacid diethyl ester (s-BPDE) homogeneous solution;

[0043] 2) Add 4.96g (0.02mol) 4-PEPA and 10g of absolute ethanol to a 50ml single-necked bottle equipped with an electromagnetic stirring device and a spherical reflux condenser, and heat, stir and reflux for 2 hours to obtain monoethyl monoformate of 4-PEPA (4-PEPE) homogeneous solution;

[0044] 3) Pour this solution into the solution in step 1), then add 18.90g (0.0944mol) 3,4'-ODA and 4.88g (0.0167mol) 1,3,4-APB, supplement ethanol to the solid of the solution The content is 47%, stirring at room temperature for 2 hours to obtain a brown polyimide resin homogeneous solution, and its rotational viscosity at 25° C. is 50-56 mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com