Preparation method of horizontal phase change storage irrelevant to photoetching resolution ratio

A technology of phase-change memory and lithographic resolution, applied in the field of preparation of horizontal phase-change memory, can solve the problem of large-area, high-precision, economical and efficient preparation, cannot realize efficient preparation of fine graphics, phase-change memory operation current Oversize and other problems, to achieve the effect of high preparation precision, simple structure, and improved integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

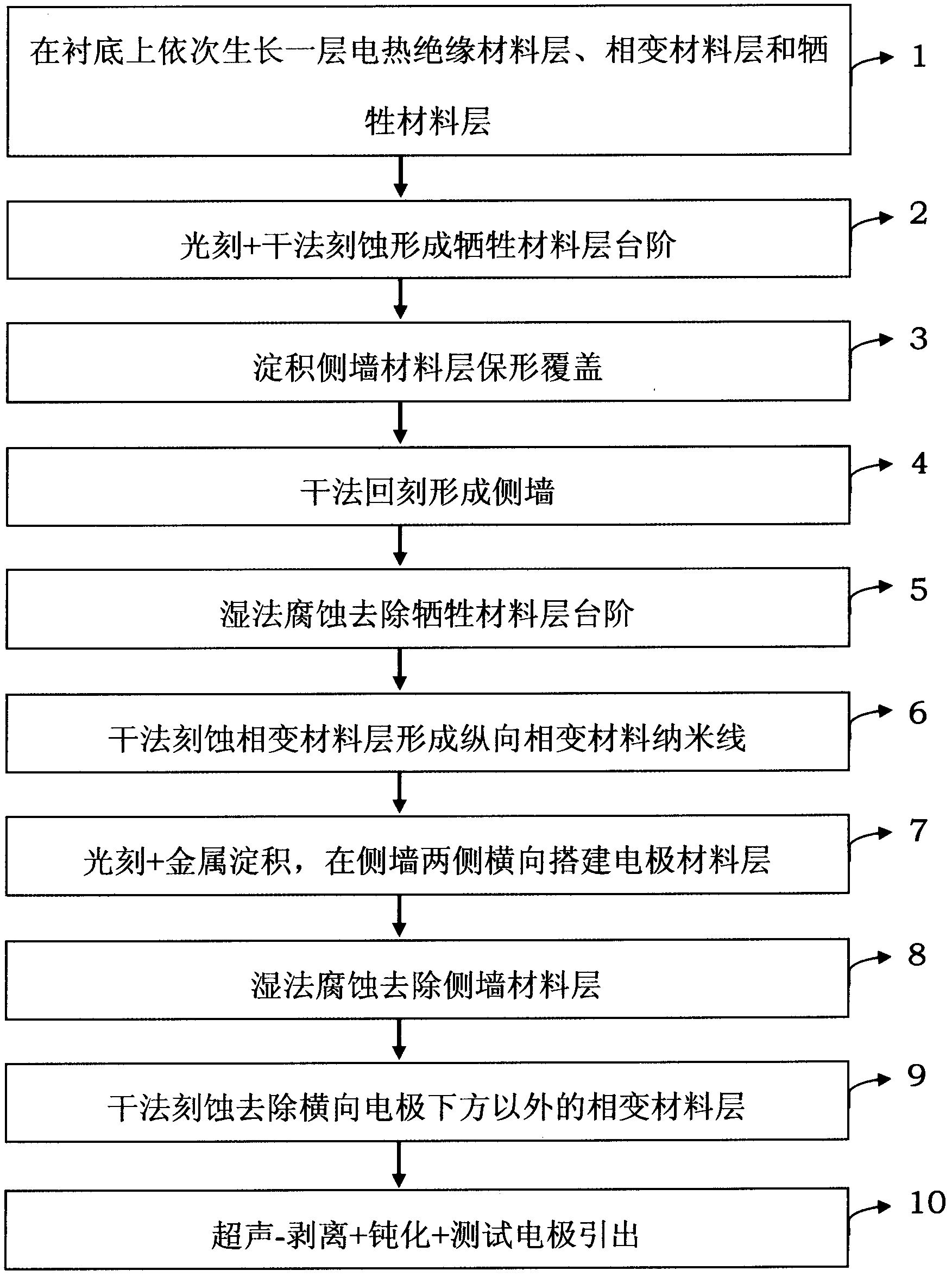

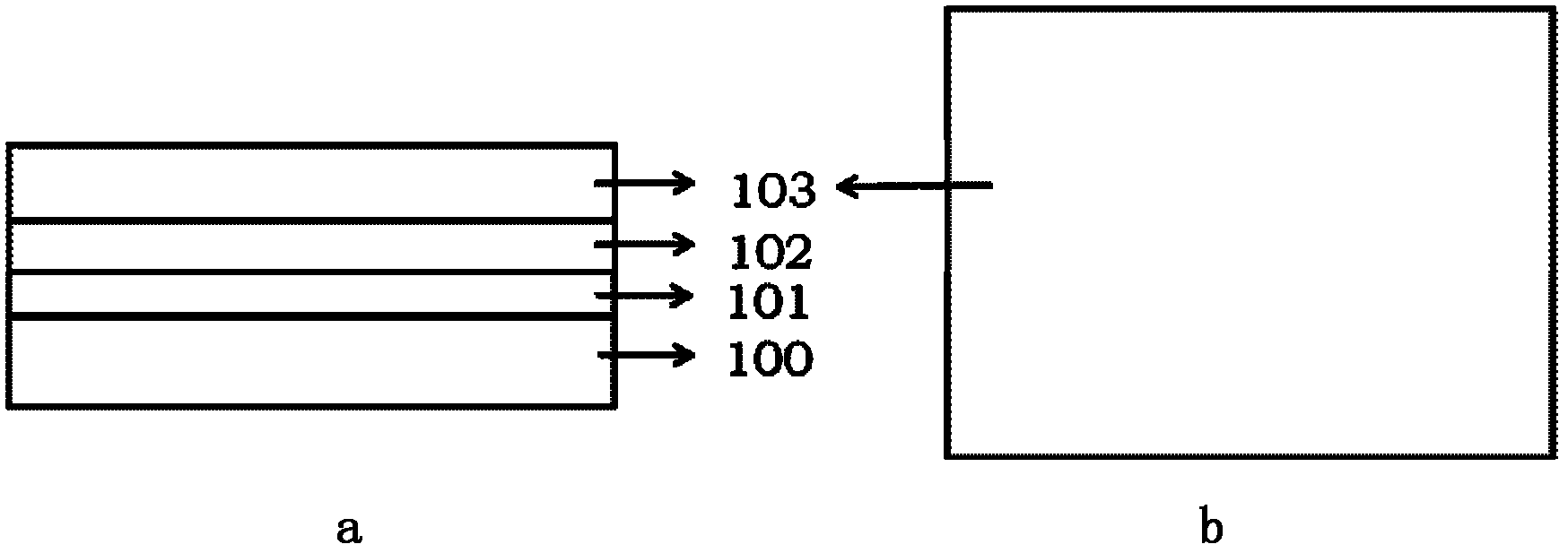

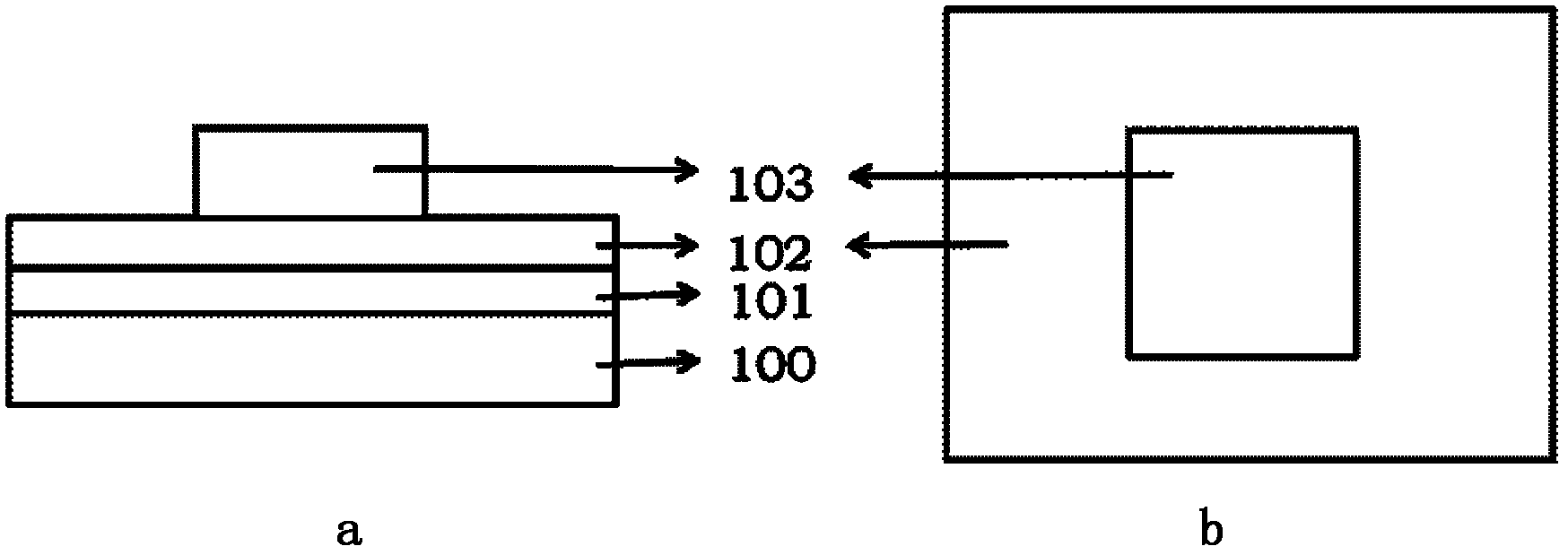

[0022] see figure 1 , see in conjunction with Figure 2 to Figure 11 As shown, the present invention provides a method for preparing a horizontal phase-change memory that has nothing to do with photolithographic resolution, the method comprising:

[0023] Step 1: grow a corrosion-resistant electrothermal insulating material layer 101 on the substrate 100, deposit a phase change material layer 102 on the electrothermal insulating material layer 101, wherein the material of the substrate 100 is silicon, gallium nitride, sapphire , silicon carbide, gallium arsenide or glass and other existing and future substrate materials. The material of the electrical insulation material layer 101 is nitrogen oxide compound, nitride or oxide, or a mixture of these compounds, and the electrical insulation material layer 101 is formed by sputtering, evaporation, chemical vapor deposition deposition method, laser-assisted deposition method, atomic layer deposition method, thermal oxidation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com