Electrocardiogram cable and manufacturing method thereof

A production method and connection technology, which is applied in the direction of cable/conductor manufacturing, conductors, circuits, etc., can solve the problems that lead wires cannot completely shield external signals, affect the accuracy of measurement results, and lead wires have no indicator lights, etc., to achieve Effects of avoiding lead contamination, improving accuracy and stability, and improving signal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

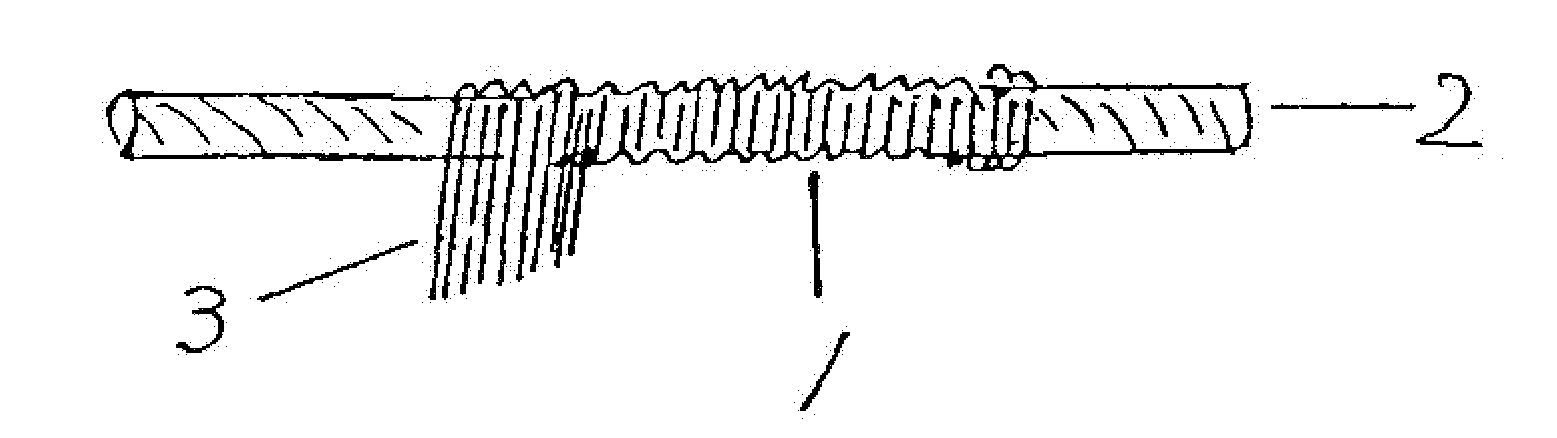

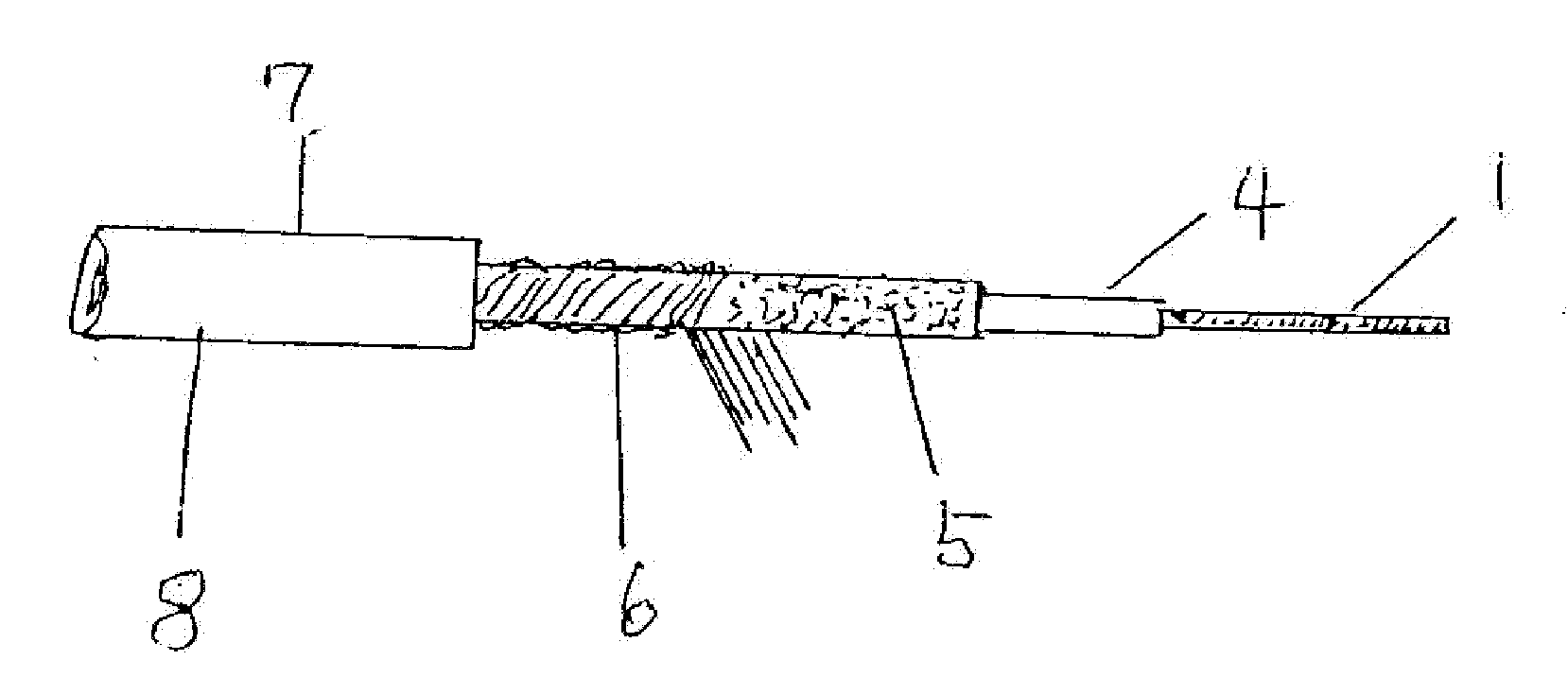

[0054] Such as figure 1 As shown, the core of the electrocardiographic lead wire of the present invention is the electrocardiographic conductor 1 that conducts the human heart electric wave to the electrocardiograph. Simultaneously helically wound (also called obliquely wound) in an S-shape on the reinforcing wire 2 to form the electrocardiographic conductor 1 .

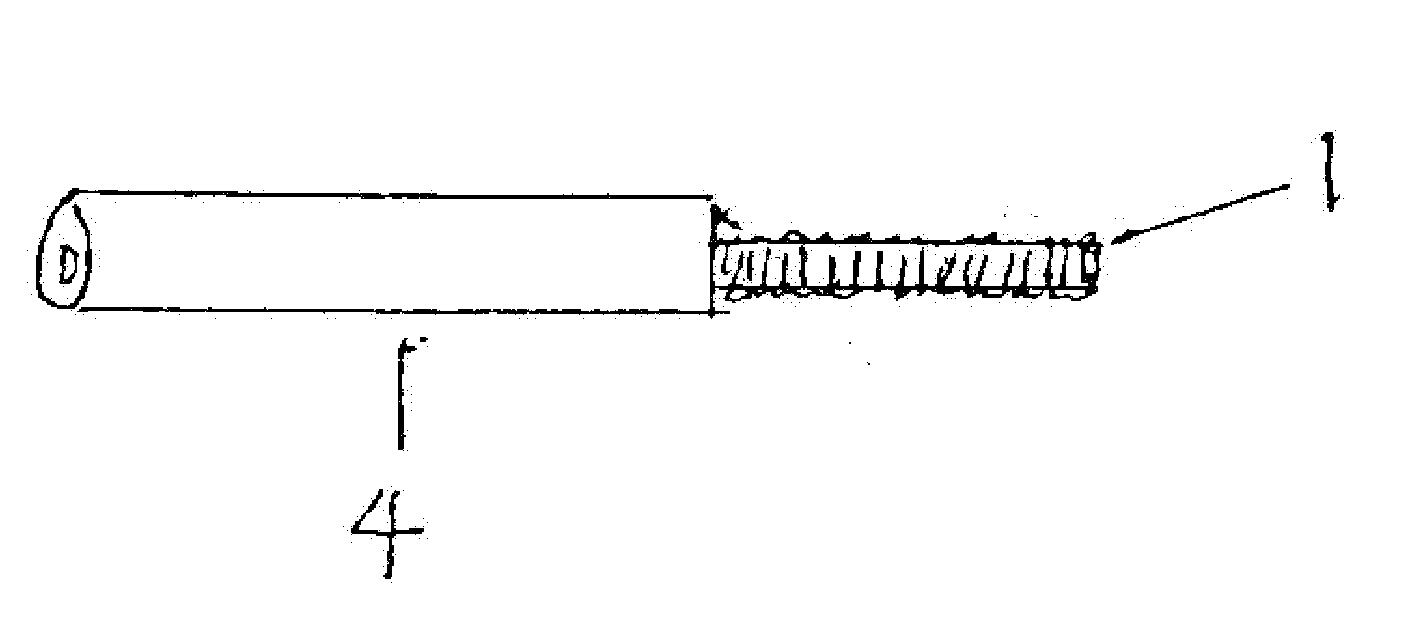

[0055] Such as figure 2 As shown, the electrocardiographic conductor 1 is covered with hard acrylic insulating resin to form the electrocardiographic inducer 4 . The reinforcing wire 2 of the electrocardiographic inducer 4 is twisted with fibers, and the tensile strength can reach more than 20kg. The thin copper wire wound on the reinforcing wire 2 is soft and can withstand strong bending. The ECG lead wire needs to be in direct contact with the human body, so it is not suitable to use a hard wire. The structure of the thin copper wire has obvious advantages in bending resistance and tensile strength, but it is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com