Modified polyurethane water-proof anticorrosive surface treating agent and preparation method as well as application thereof

A polyurethane waterproof and surface treatment agent technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of difficulty in achieving durability, heavy-duty anti-corrosion, and single performance, and achieve good surface energy , Improve crosslinking strength and durability, simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

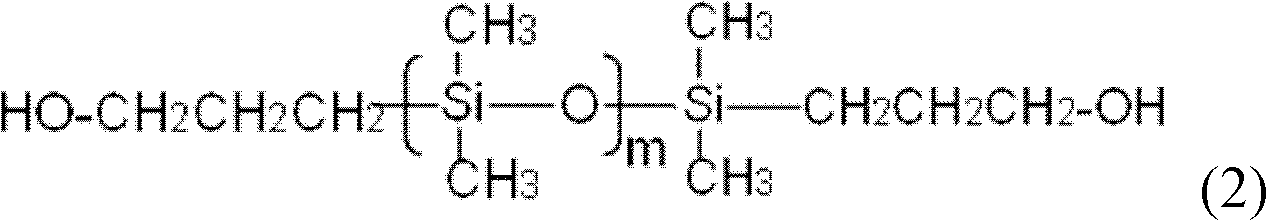

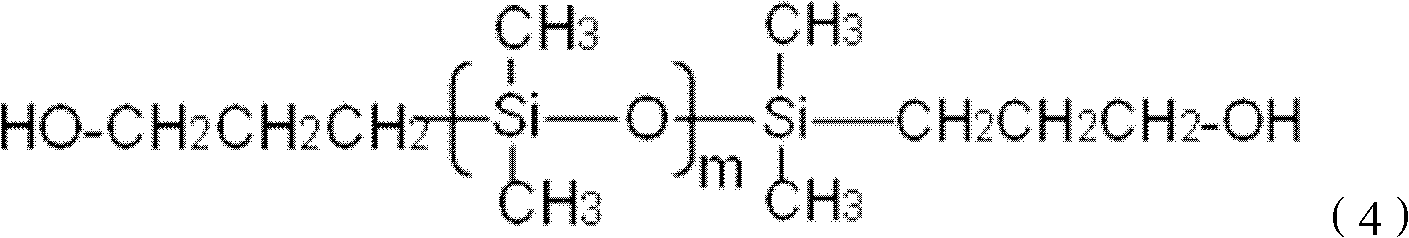

[0047] In a stainless steel reaction kettle equipped with a stirring blade, a condenser tube, a thermometer and a nitrogen purge tube, add 111 grams (0.5 mol) of isophorone diisocyanate (IPDI) with a weight average molecular weight of 2000 dihydroxyl-terminated polysiloxane 200 grams (0.1mol) of alkane, 0.2 grams of dibutyltin dilaurate, dry N 2 Under protection, react at 90°C for 1 hour, lower the temperature to 50°C, add 400 g of solvent butyl acetate, 22 g (0.24 mol) of butanediol, and perform chain extension reaction for 1 hour under stirring, then raise the temperature of the reactor to 70°C, add Perfluorohexyl ethanol (C 6 f 13 CH 2 CH 2 OH) 65 grams (0.18mol), aminopropyl triethoxysilane 6.6 grams (0.03 mol), carry out end-capping reaction 2 hours at this temperature, make fluorine / silicon modified polyurethane waterproof and anticorrosion surface treatment agent 693.8 grams , The solid content is 42.3%.

Embodiment 2

[0049] In a stainless steel reaction kettle equipped with a stirring blade, a condenser tube, a thermometer and a nitrogen purge tube, 80 grams (0.45mol) of toluene diisocyanate (TDI) and 150 grams of dihydroxy-terminated polysiloxane with a weight average molecular weight of 1000 were added (0.15mol), 0.15 grams of dibutyltin dilaurate, dry N 2 React at 80°C for 1 hour under protection, cool down to 50°C, add 400 g of solvent butyl acetate, 12 g (0.13 mol) of butanediol, and perform chain extension reaction for 1 hour under stirring, then raise the temperature of the reactor to 70°C, add N methyl perfluorohexyl sulfonamide ethanol (C 6 f 13 SO 2 N(CH 3 )CH 2 CH 2 OH) 100 grams (0.22mol), aminopropyltriethoxysilane 6.6 grams (0.03mol), carry out end-capping reaction 2 hours at this temperature, make fluorine / silicon modified polyurethane waterproof anticorrosion surface treatment agent 748.8 grams , The solid content is 46.5%.

Embodiment 3

[0051] In the stainless steel reaction kettle that stirrer blade, condensing pipe, thermometer and nitrogen purge pipe are housed, add isophorone diisocyanate (IPDI) 80 grams (0.36mol), triphenylmethane triisocyanate 50g (0.14mol), The weight-average molecular weight is 3000, 500 grams (0.17mol) of dihydroxyl-terminated polysiloxane, 0.3 grams of zinc octoate, dry N 2 Under protection, react at 90°C for 1 hour, lower the temperature to 60°C, add 500 grams of solvent methyl ethyl ketone, 25 g (0.28 mol) of butanediol, and perform chain extension reaction for 1 hour under stirring, then raise the temperature of the reactor to 70°C, add perfluorinated Butyl ethanol (C 4 f 9 CH 2 CH 2 OH) 50 grams (0.19mol), 9 grams (0.04mol) of aminopropyltriethoxysilane, carry out capping reaction 1.5 hours at this temperature, make 1214.3 grams of fluorine / silicon modified polyurethane waterproof anticorrosion surface treatment agent , The solid content is 58.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com