Preparation method of zirconium boride ceramic fibre

A technology of ceramic fiber and zirconium boride, which is applied in the field of preparation of zirconium boride ceramics, can solve the problems of unsatisfactory performance, no ceramic fiber method, etc., and achieves the effects of low equipment requirements, low cost and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

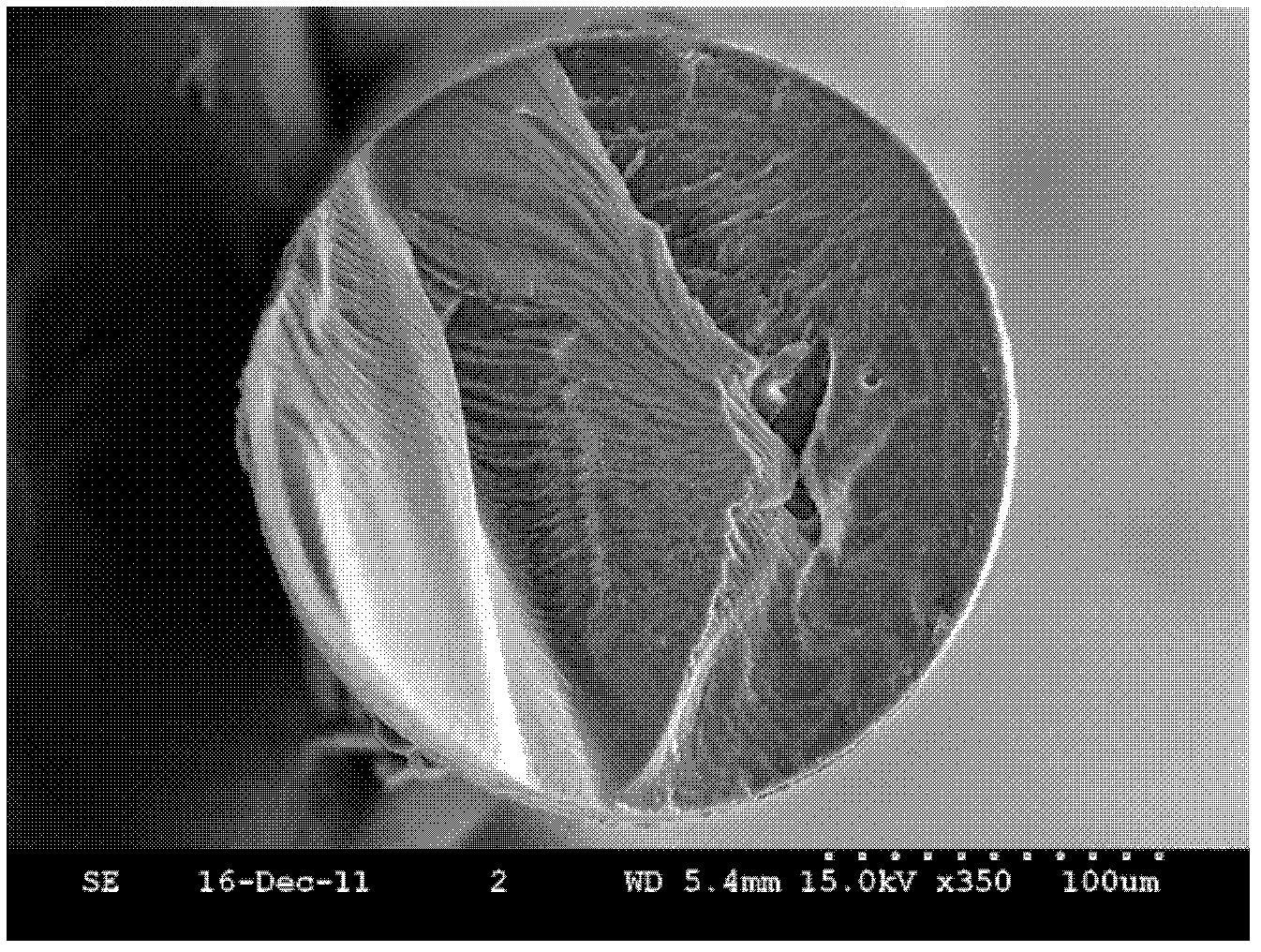

Embodiment 1

[0030] Will contain 8.646g ZrOCl 2 Add the aqueous solution containing 4.473g of borax drop by drop to the aqueous solution containing borax, fully stir until the mixture is uniform, then add the aqueous solution of sucrose containing 4.853g and the aqueous solution of citric acid containing 16.811g, mix uniformly, adjust the pH value of the system to 3, and react for 10h , to obtain a precursor solution; 17.146g of polyethylene oxide was dissolved in 60ml of 1:4 water-alcoholic solvent, mixed uniformly with the above-mentioned precursor solution at 50°C, concentrated until the viscosity reached 50Pa·s, and left standing for defoaming. Get ZrB 2 Precursor spinning solution for ceramic fibers. Spinning liquid at 60 ° C using solution spinning method to obtain ZrB 2 Ceramic fiber precursor, obtained after high temperature sintering ZrB 2 Ceramic fiber.

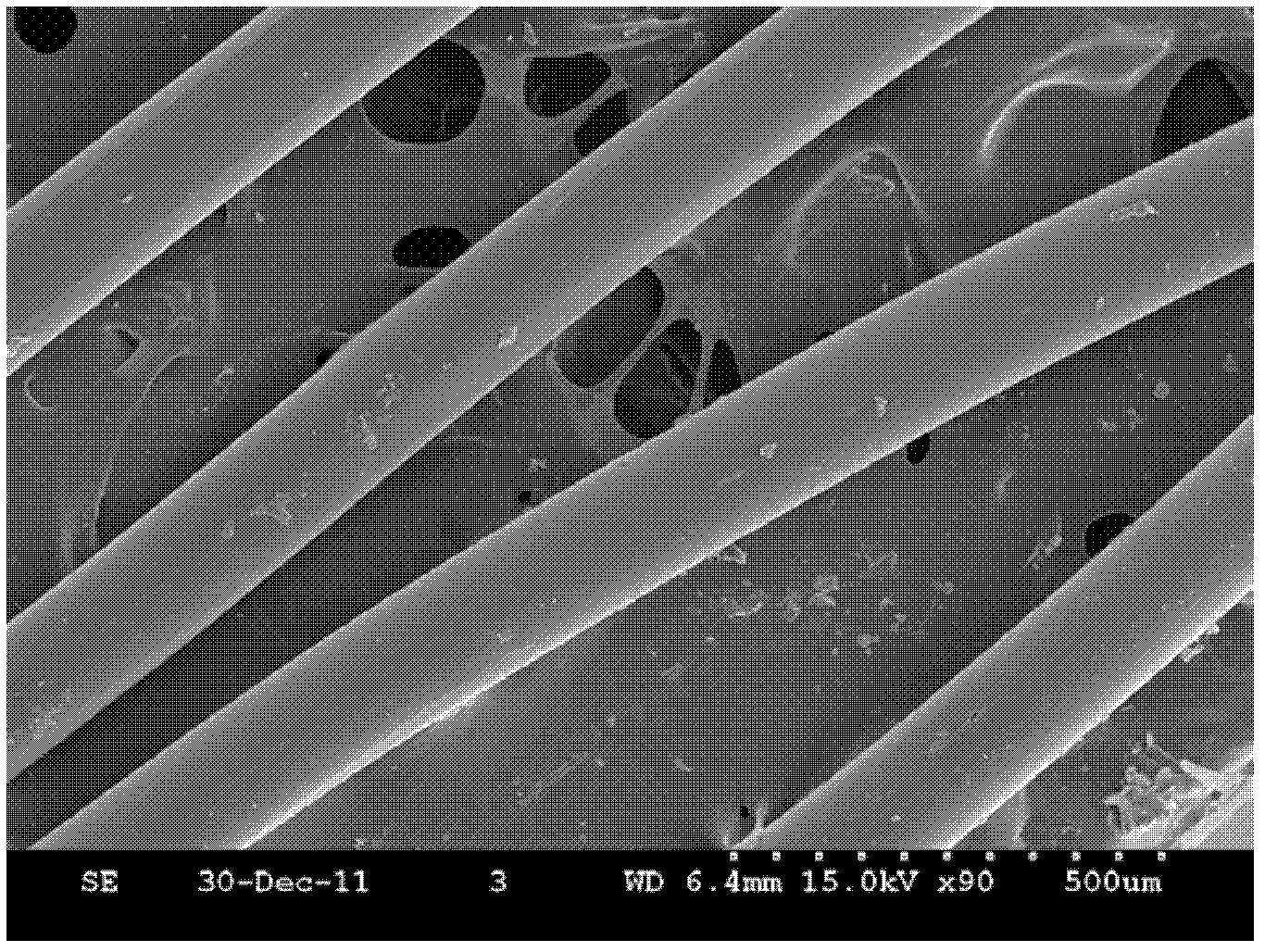

Embodiment 2

[0032] Will contain 15.645g Zr(NO 3 ) 4 The aqueous solution was added dropwise to the aqueous solution containing 3.647g of boric acid under stirring, fully stirred until uniformly mixed, and then added with a 1:1 water-alcohol solvent to dissolve 3.873g of thermosetting phenolic resin and the aqueous solution containing 12.232g of citric acid, Mix well, adjust the pH value of the solution to 3, react for 14h, dissolve 30.799g polyvinyl alcohol in 100ml 1:4 water-alcohol solvent, mix well with the above precursor solution at 60°C, concentrate until the viscosity reaches 50Pa· s, standing for defoaming, to get ZrB 2 Precursor spinning solution for ceramic fibers. The spinning solution was spun at 50°C to obtain ZrB by solution spinning 2 Ceramic fiber precursor, after a suitable calcination process, ZrB 2 Ceramic fiber.

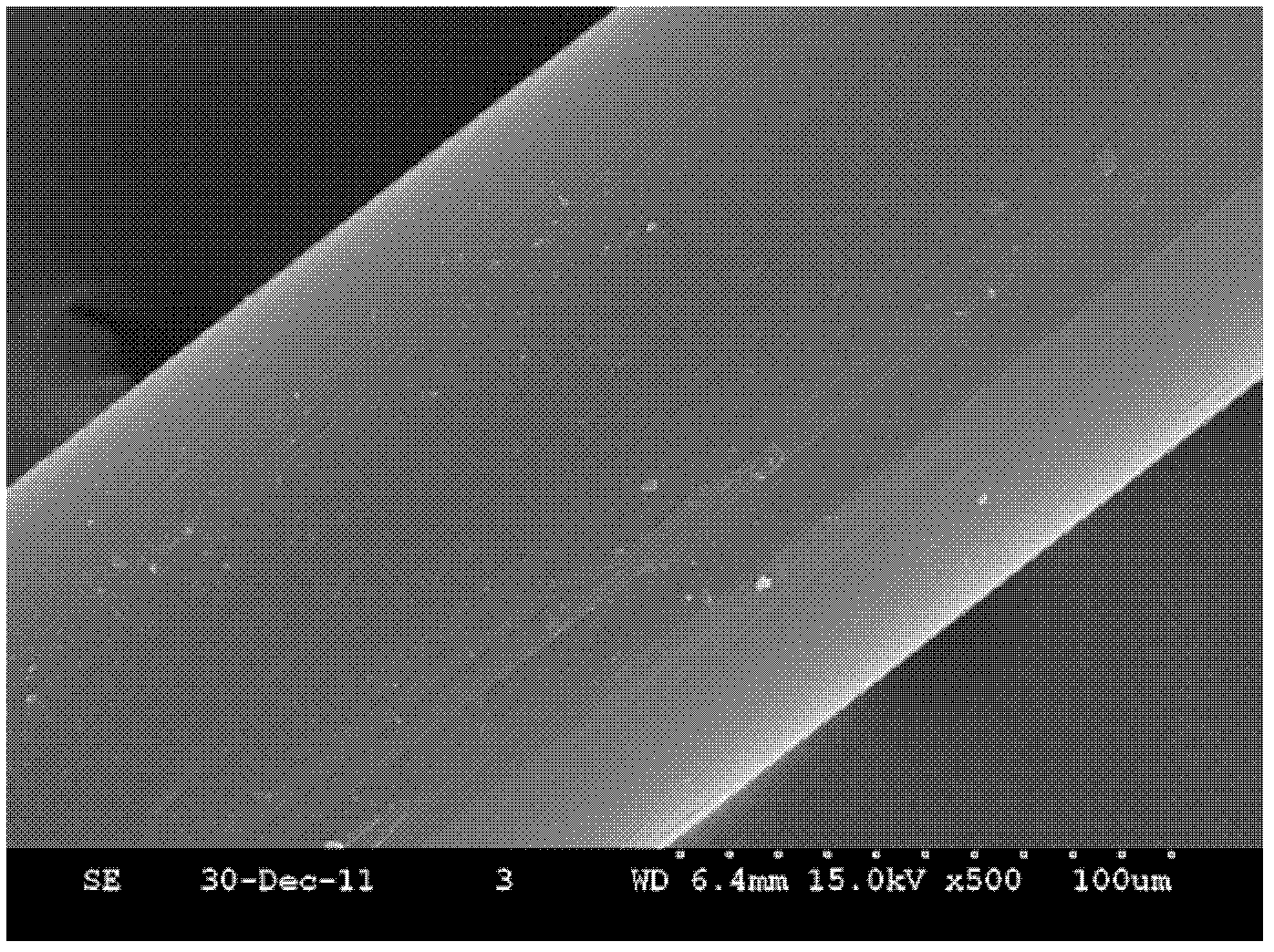

Embodiment 3

[0034] Will contain 14.245g ZrOCl 2 ·8H 2 Add O aqueous solution dropwise to the stirring aqueous solution containing 7.436g of boric acid, stir well until mixed evenly, then add 2.643g sucrose aqueous solution and 15.811g acetic acid aqueous solution respectively, mix uniformly, adjust the pH value of the system to 2, and react for 11h , dissolve 20.998g hydroxypropyl cellulose in 80ml 1:4 water-alcohol solvent, mix well with the above precursor solution at 30°C, concentrate until the viscosity reaches 80Pa·s, stand for defoaming, and obtain ZrB 2 Precursor spinning solution for ceramic fibers. The spinning solution was spun at 70°C to obtain ZrB 2 Ceramic fiber precursor, after a suitable calcination process, ZrB 2 Ceramic fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com