Large-diameter seamless pipe made of X80-grade high-strength and toughness pipeline steel and method for manufacturing large-diameter seamless pipe

A technology of large-diameter and tough pipelines, which is applied in the field of large-diameter seamless pipe manufacturing to achieve the effect of reducing reheating links, good comprehensive performance and high resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

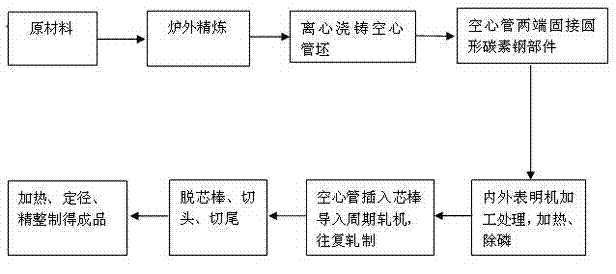

Method used

Image

Examples

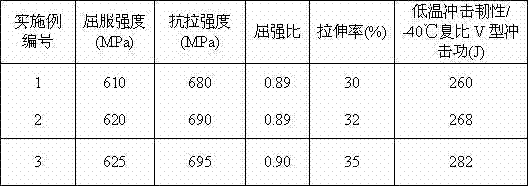

Embodiment 1

[0057] Using low C-Mn-Nb-Mo series microalloying alloy composition, the raw materials with the following chemical composition weight percentage are refined with high cleanliness:

[0058] C: 0.01%, Mn: 1.50%, Si: 0.20%, S: 0.001%, P: 0.01%, Nb: 0.03%, Ti: 0.005%, V: 0.04%, Al: 0.030%, N: 0.0050%, Mo: 0.05%, Cu: 0.10%, Ni: 0.05%, Cr: 0.10%, Ca: 0.001%.

[0059] Refined molten steel is centrifugally cast into a hollow billet of F820×130mm, and the two ends of the hollow billet are fixed with carbon steel as the bite head and tail end parts. The length of the bite head is 300mm, and the round part of the tail end is F720× 30mm×600mm, the outer surface of the carbon steel at the head end is processed into a taper of 1:1.5, the inner and outer surfaces of the tube blank and the carbon steel end are machined, and the inner and outer surfaces are cut by 5mm and 2mm respectively to obtain a carbon steel section at both ends The size of the tube blank is F802×112×1980mm. Heat the abo...

Embodiment 2

[0061] Using low C-Mn-Nb-Mo series microalloying alloy composition, the raw materials with the following chemical composition weight percentage are refined with high cleanliness:

[0062] C: 0.03%, Mn: 1.75%, Si: 0.25%, S: 0.0020%, P: 0.012%, Nb: 0.05%, Ti: 0.01%, V: 0.06%, Al: 0.040%, N: 0.0080%, Mo: 0.20%, Cu: 0.30%, Ni: 0.15%, Cr: 0.30%, Ca: 0.004%.

[0063] Refined molten steel is centrifugally cast into a hollow billet of F850×135mm, and the two ends of the hollow billet are fixed with carbon steel as the bite head and tail end parts. The length of the bite head is 400mm, and the round part of the tail end is F740× 35mm×750mm, the outer surface of the carbon steel at the front end is processed into a taper of 1:2.4, the inner and outer surfaces of the tube blank and the carbon steel end are machined, and the inner and outer surfaces are cut by 6mm and 2mm respectively. The size of the tube blank with carbon steel sections at both ends is F830×113×2000mm. The above-menti...

Embodiment 3

[0065] Using low C-Mn-Nb-Mo series microalloying alloy composition, the raw materials with the following chemical composition weight percentage are refined with high cleanliness:

[0066] C: 0.050%, Mn: 2.00%, Si: 0.30%, S: 0.0030%, P: 0.015%, Nb: 0.08%, Ti: 0.03%, V: 0.08%, Al: 0.050%, N: 0.010%, Mo: 0.50%, Cu: 0.50%, Ni: 0.35%, Cr: 0.50%, Ca: 0.006%.

[0067]Refined molten steel is centrifugally cast into a hollow billet of F860×140mm, and carbon steel is fixed at both ends of the hollow billet as the biting head and tail end parts. The length of the biting head is 500mm, and the round part of the tail end is F750 ×40mm×900mm, the outer surface of the carbon steel at the front end is processed into a taper of 1:3.1, the inner and outer surfaces of the tube blank and the carbon steel end are machined, and the inner and outer surfaces are cut by 6mm and 3mm respectively. The size of the tube blank with carbon steel sections at both ends is F840×120×2100mm. The above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com