Cellulose base - silicon hybridization microsphere and preparation method thereof

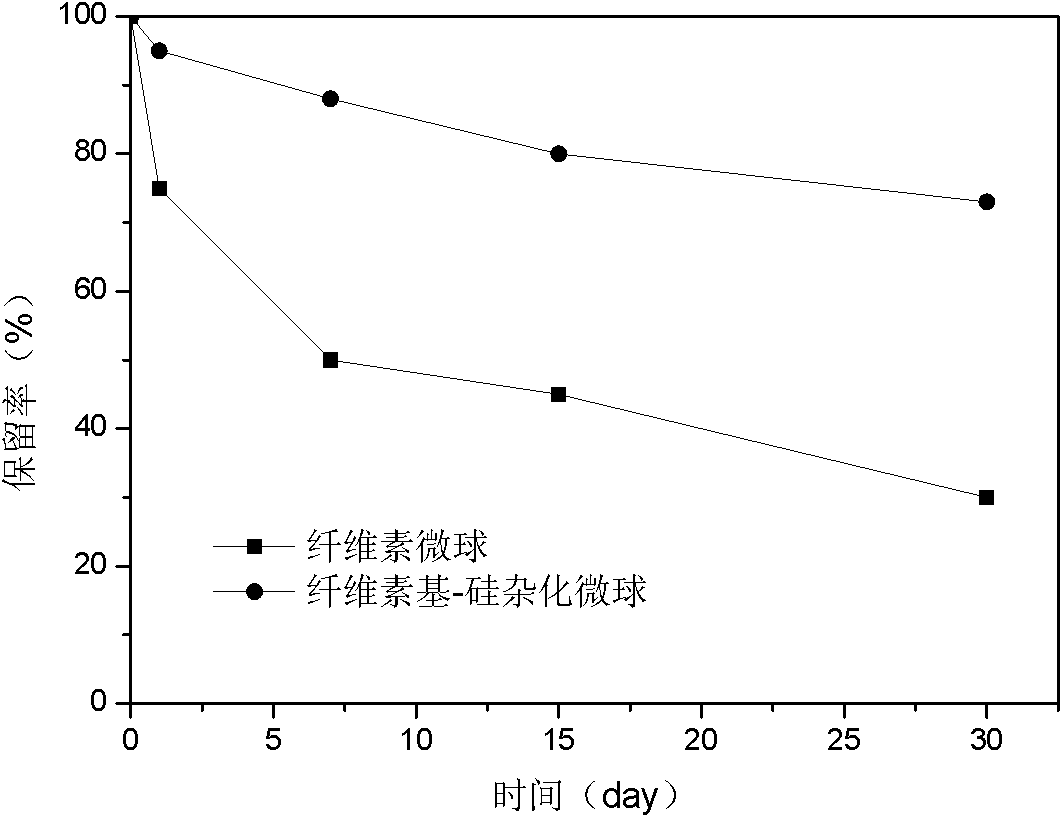

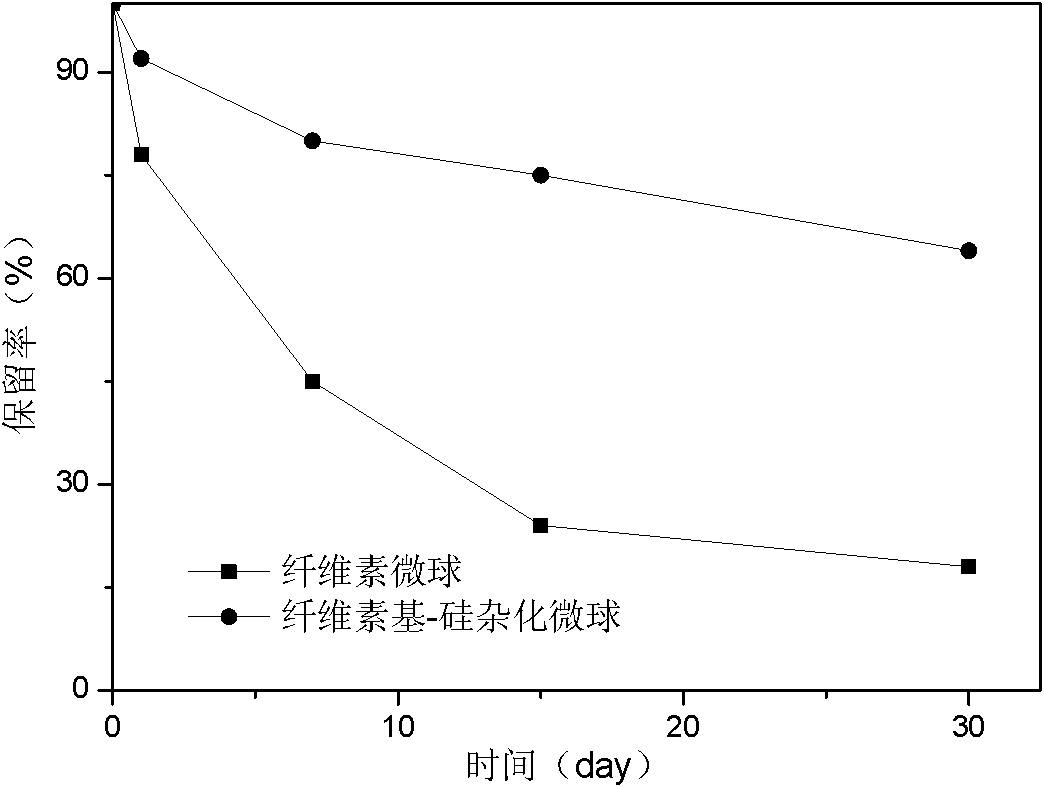

A cellulose-based, silicon-hybridized technology, applied in the field of polymer chemistry, can solve problems such as small application range, and achieve the effects of low cost, good pore structure, enhanced pore structure and adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation process of the above cellulose-silicon hybrid microspheres is divided into two steps: the preparation of the cellulose-sodium silicate homogeneous solution and the preparation of the cellulose-silicon hybrid microspheres.

[0023] Preparation of cellulose-sodium silicate homogeneous solution: add sodium silicate to alkali / urea aqueous solution or alkali / thiourea aqueous solution, freeze to -12℃~-5℃, then add cellulose, stir at 200~1500r / min After dissolving the cellulose, it is centrifuged at low speed to defoam and remove impurities to obtain a cellulose-sodium silicate homogeneous solution.

[0024] Preparation of cellulose-based silicon hybrid microspheres: Disperse the cellulose-sodium silicate homogeneous solution in an organic solvent of an emulsifier or a compound emulsifier, stir at 300-1500r / min until the droplet is uniformly dispersed, and then Stir under low temperature for 1-8 hours to form, add dilute acid until the solution system is acidic...

Embodiment 1

[0027] Add 5g sodium silicate nonahydrate to 100g aqueous solution containing 6g NaOH and 16g urea, dissolve and freeze to -12°C, then add 5g cellulose, stir vigorously at 1500r / min to dissolve the cellulose. Add 300mL of liquid paraffin and 5g of Span 85 emulsifier into a 500mL three-necked flask equipped with a reflux condenser and a constant temperature water bath, and stir at 500r / min to disperse evenly, then slowly add the homogeneous cellulose-sodium silicate prepared by the above method After stirring 50 mL of the solution at room temperature for 1 h, add 10% hydrochloric acid until the solution is acidic (pH2 / g, its scanning electron microscope picture is shown in figure 1 .

Embodiment 2

[0029]Add 1g sodium silicate nonahydrate to 100g aqueous solution containing 6g NaOH and 16g urea, dissolve and freeze to -10°C, then add 5g cellulose, stir vigorously at 1000r / min to dissolve the cellulose. In a 500mL three-neck flask equipped with a reflux condenser and a constant temperature water bath, add 300mL of petroleum ether and n-hexane mixed solvent (volume ratio is 1 / 1), and 2g of Span 60 and 6g of Span 80 mixed emulsifier, 800r / min After stirring to disperse evenly, slowly add 100 mL of cellulose-sodium silicate homogeneous solution prepared by the above method, stir at room temperature for 2 hours, add 10% hydrochloric acid until the solution is acidic (pH2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com