Engine waste gas aftertreatment system

An exhaust gas post-treatment and engine technology, which is applied in exhaust gas treatment, engine components, combustion engines, etc., can solve the problems of polluted environment, incomplete purification of combustion exhaust gas, incomplete after-treatment reaction, etc., achieves exhaust gas purification thoroughly, and is easy to promote , the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

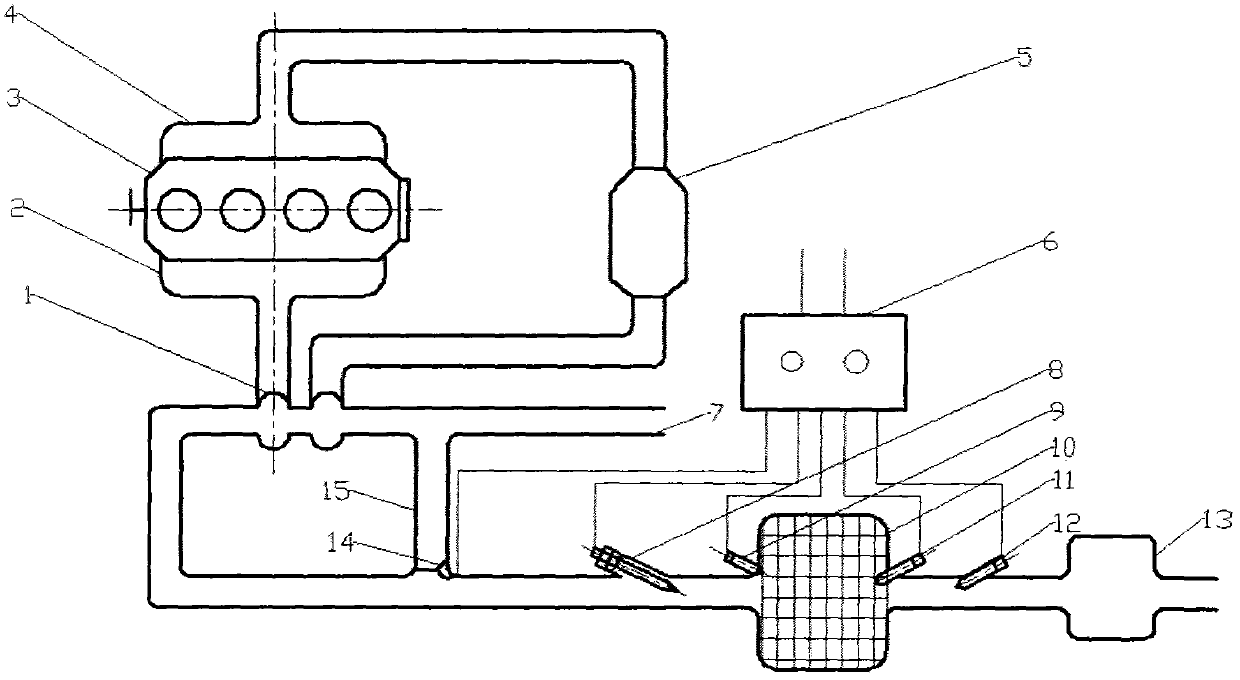

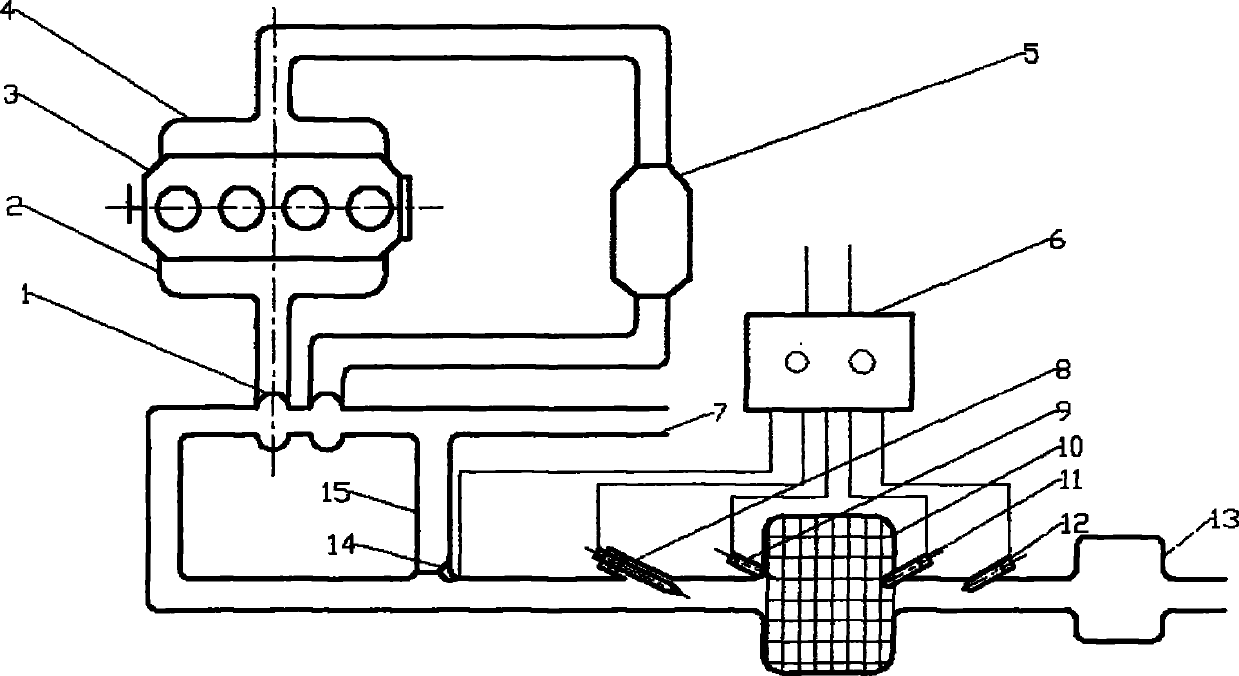

[0023] Such as figure 1 As shown, the engine exhaust gas aftertreatment system of the present invention comprises a catalytic converter 10, which is provided with a catalyst nozzle 8, and the nozzle 8 is controlled by an ECU (Electronic Control Unit) 6 to eject the catalyst. Non-"backward drag" working condition) makes the high-temperature exhaust gas entering the catalytic converter 10 fully purified, and the purified gas enters the muffler 13 and is discharged into the atmosphere. The front end of the post-processing system also includes: turbocharger 1, engine exhaust pipe 2, engine 3, engine intake pipe 4, intake intercooler 5, and compressor intake pipe 7. The connection of these devices constitutes the intake and exhaust pipe of the engine. Inner loop. The turbocharger 1 is connected via a line to the catalytic converter 10 (through which exhaust gas can enter the catalytic converter). In order to avoid the low-temperature gas discharged from the engine exhaust pipe 2 ...

Embodiment 2

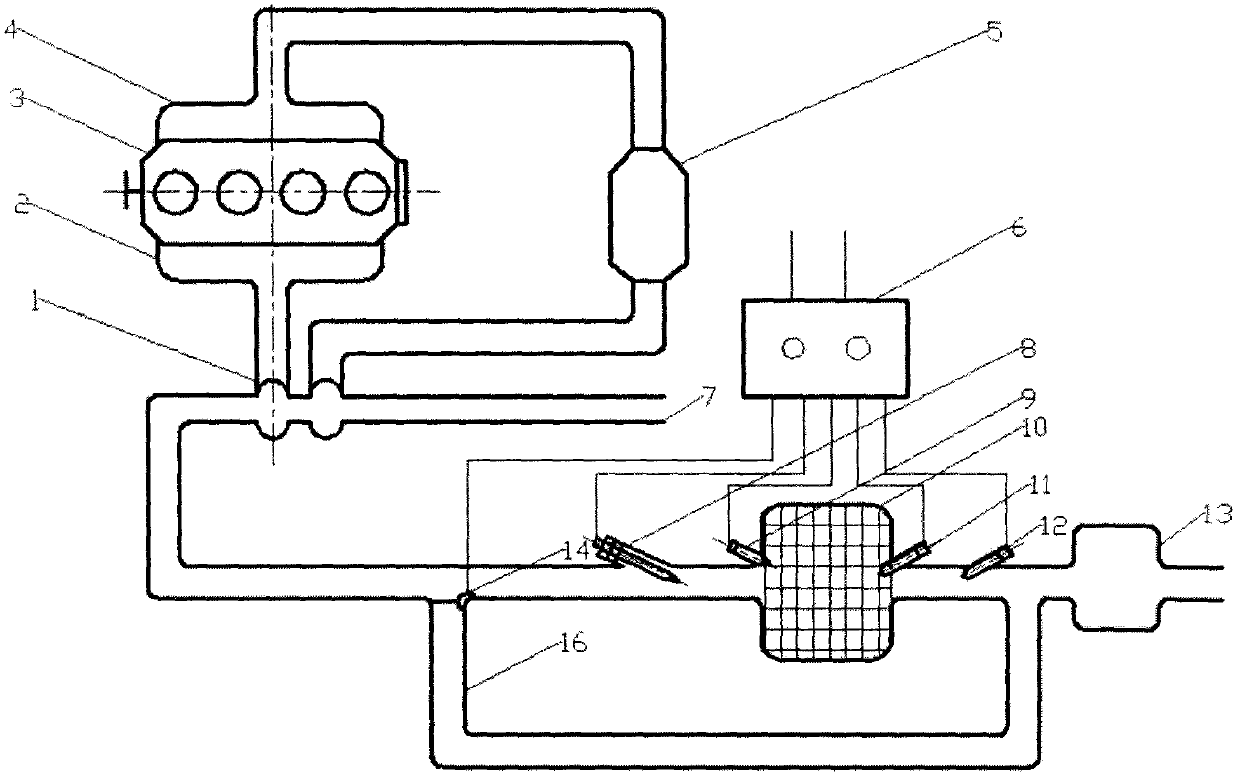

[0028] The scheme of embodiment 2 allows the unburned air to be introduced into the muffler intake end when the engine is "dragging backwards", avoiding the cooling of the after-treatment system by the low-temperature exhaust gas, and also keeping the exhaust gas purified by the after-treatment system at a higher level, which is more environmentally friendly.

[0029] The flow direction of the exhaust in the above-mentioned embodiments 1 and 2 is controlled by the opening and closing of the exhaust switching valve 14, and its action execution is integrated and managed by the engine control system ECU. The return pipeline 15 of embodiment 1 and the bypass pipeline of embodiment 2 can be connected with the main exhaust pipe of the system with a flange, but the specific implementation is not limited thereto.

[0030] The outlet of the catalytic converter 10 is also equipped with a purified exhaust pollutant sensor 11 for detecting pollutant indicators. The sensor 11 is monitored b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com