Organic-inorganic compound fertilizer added with SOD (Super Oxygen Dehydrogenise) analogue and production method thereof

A technology of compound fertilizers and simulants, applied in the direction of fertilizer mixtures, fertilization devices, applications, etc., to achieve nutritional balance, improve plant resistance to adversity, and uniform particle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

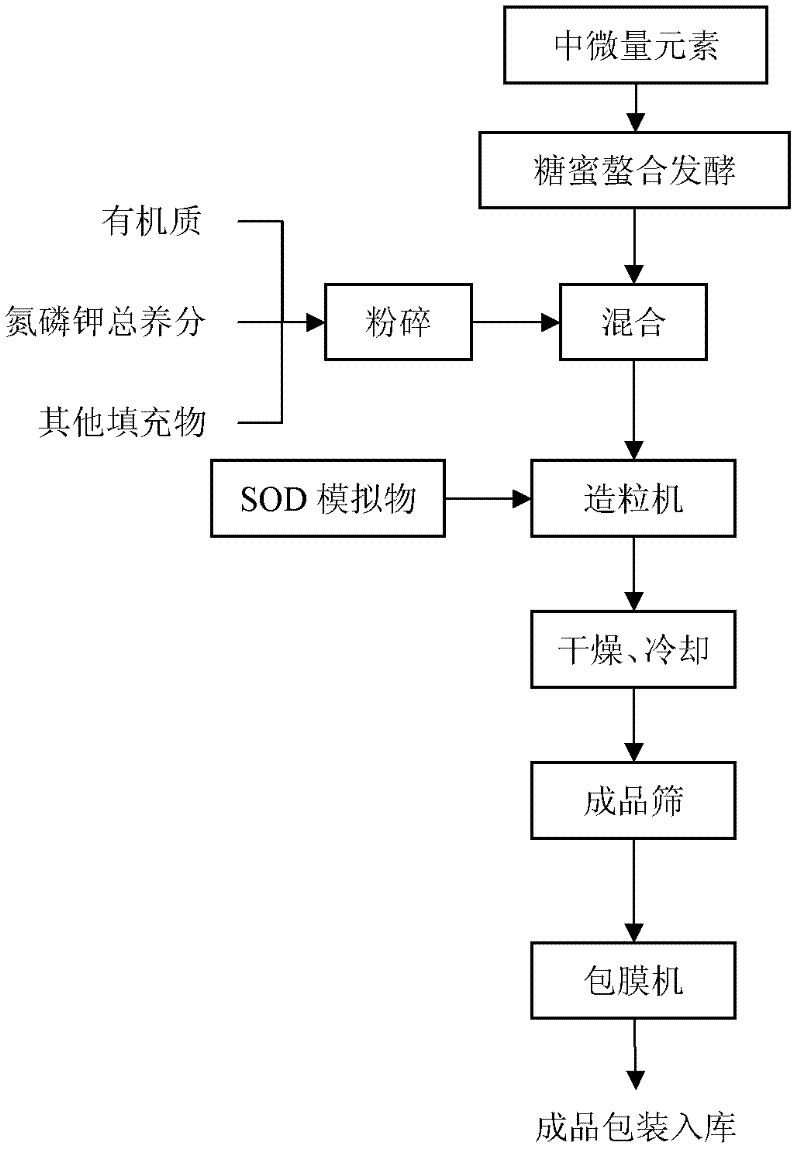

Method used

Image

Examples

Embodiment 1

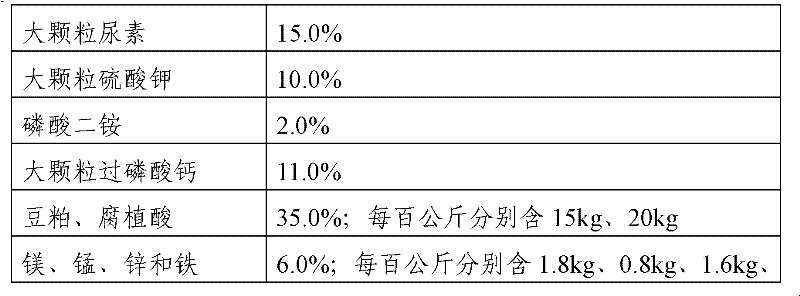

[0057] Described fertilizer, by weight percentage, raw material component is as follows (the component of fertilizer after every hundred kilograms of granulation):

[0058]

[0059]

[0060] Preparation:

[0061] (1) Crushing and mixing of raw materials: total nitrogen, phosphorus and potassium nutrients (large-grained urea, large-grained potassium sulfate, diammonium phosphate and large-grained superphosphate), organic matter (soybean meal) and other fillers (diatomaceous earth and Bentonite) is crushed to 0.6mm respectively, humic acid is crushed to 0.1mm; the trace elements (magnesium, manganese, zinc and iron) in the raw material after pulverizing and chelated state are mixed evenly;

[0062] (2) Adjustment of pH of raw materials: add calcium magnesium phosphate fertilizer to the raw materials mixed in the previous step to neutralize the free acid in superphosphate, and control the pH value of the fertilizer to 5.5 after mixing to ensure the effectiveness of nutrient...

Embodiment 2

[0066] Described fertilizer, by weight percentage, raw material component is as follows (the component of fertilizer after every hundred kilograms of granulation):

[0067]

[0068]

[0069] Preparation:

[0070] (1) Crushing and mixing of raw materials: total nitrogen, phosphorus and potassium nutrients (large-grain urea, large-grain potassium sulfate, diammonium phosphate and large-grain superphosphate), organic matter (bran meal and soybean meal) and other fillers (silicon algae and attapulgite) were crushed to 0.7mm respectively, humic acid was crushed to 0.15mm; the raw materials after crushing were mixed evenly with trace elements (boron, molybdenum, copper, zinc, iron) in the chelated state;

[0071] (2) Adjustment of pH of raw materials: add calcium magnesium phosphate fertilizer to the raw materials mixed in the previous step to neutralize the free acid in superphosphate, and control the pH value of the fertilizer to 6.2 after mixing to ensure the effectiveness ...

Embodiment 3

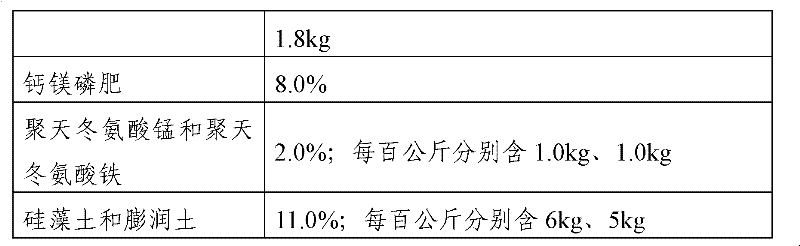

[0075] Described fertilizer, by weight percentage, raw material component is as follows (the component of fertilizer after every hundred kilograms of granulation):

[0076]

[0077]

[0078] Preparation:

[0079] (1) Crushing and mixing of raw materials: total nitrogen, phosphorus and potassium nutrients (large-grained urea, large-grained potassium sulfate, diammonium phosphate and large-grained superphosphate), organic matter (plant ash) and other fillers (diatomaceous earth and Vermiculite) is crushed to 0.8mm respectively, and humic acid is crushed to 0.2mm; The trace elements (magnesium, manganese, zinc, iron, selenium) in the raw material after pulverizing and chelated state are mixed evenly;

[0080] (2) Adjustment of raw material pH: add calcium magnesium phosphate fertilizer to the raw material mixed in the previous step to neutralize the free acid in superphosphate, and control the pH value of the fertilizer to 6.8 after mixing to ensure the effectiveness of nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com