Device and method for feeding rare earth alloy during continuous casting process

A rare earth alloy and continuous casting technology, which is applied in the field of smelting, can solve the problems of uneven distribution of rare earth and sulfur, insufficient diffusion of rare earth, and late addition of rare earth, so as to achieve long melting and dissolution time, eliminate longitudinal crack defects, and improve internal quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

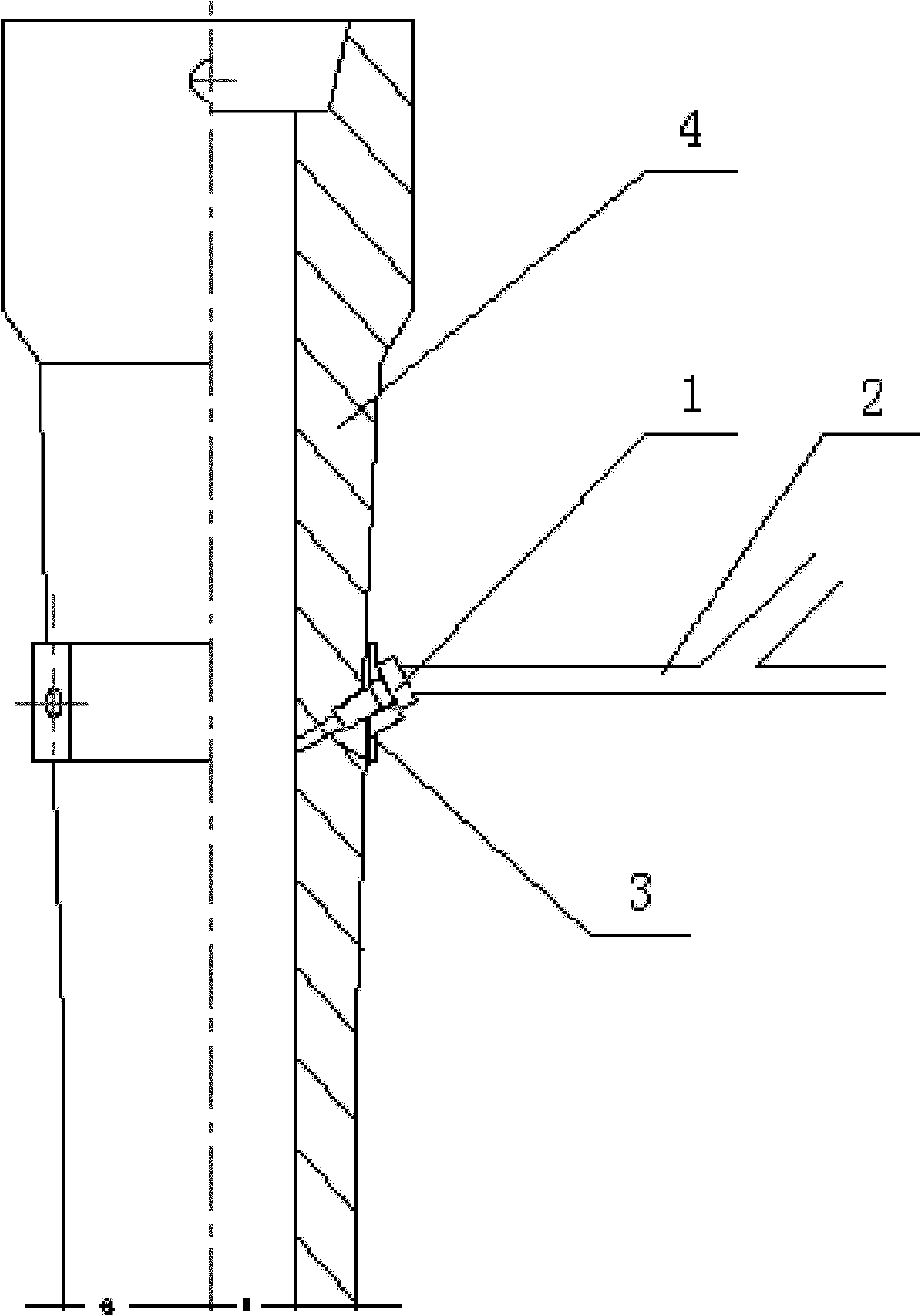

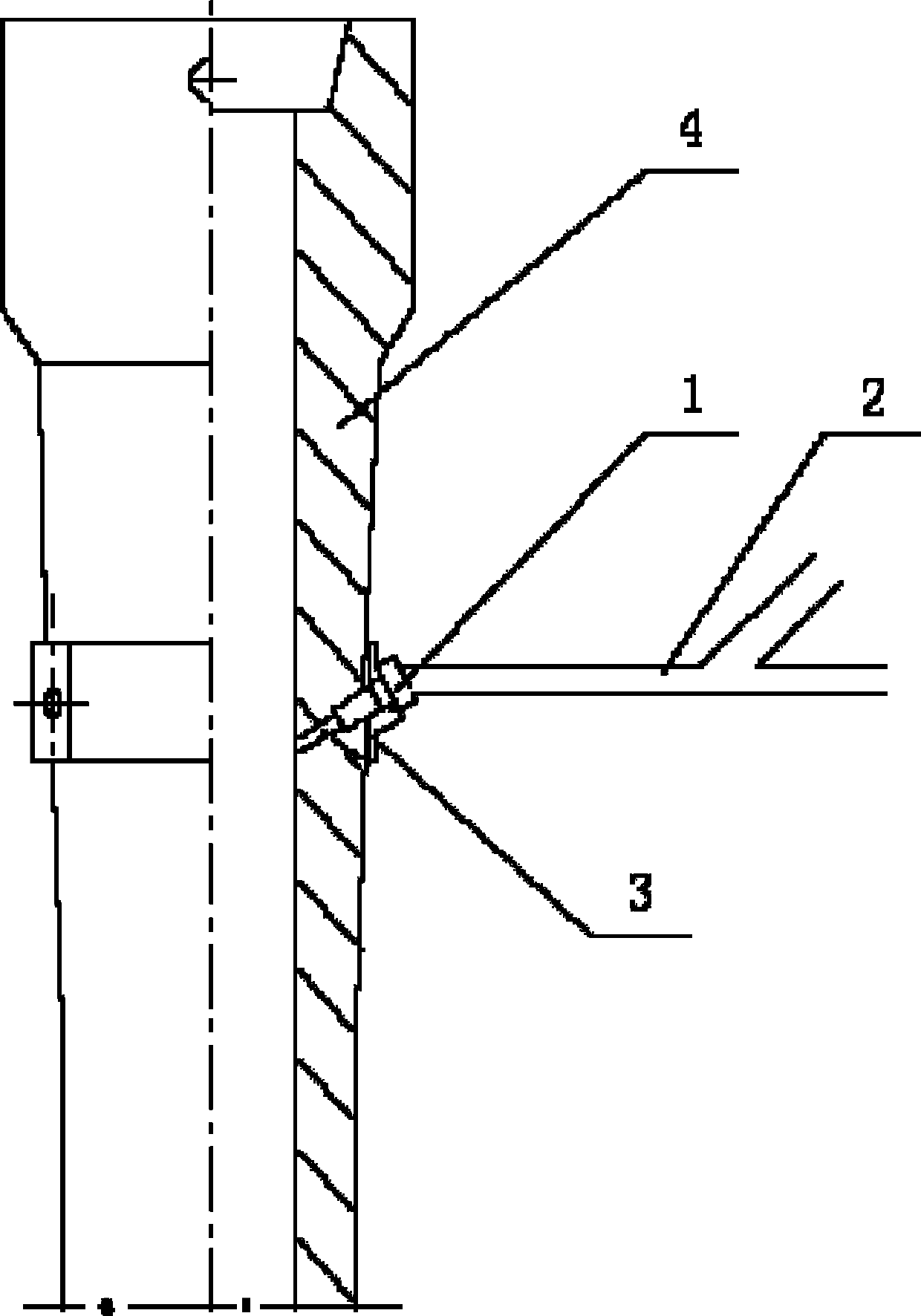

[0030] The inner diameter of the joint 1 is 10 mm, the outer diameter of the metal tee pipe 2 straight pipe and the inclined pipe are both 10 mm, and the angle between the straight pipe axis and the inclined pipe axis of the metal tee pipe 2 is 30°. A two-strand slab continuous casting machine is adopted, the cross-section of the slab is 1150×230 mm, and the casting speed is 1.2 m / min.

[0031] First, drilling and equipment connections are made. During the pouring process of the molten steel tank, two holes with a diameter of 13mm are symmetrically drilled with an electric drill along the radial direction of the outer wall of the long nozzle 4 of the tundish. The angle is 10°. Insert the lower parts of the joints 1 of the two pre-installed feeding devices into their respective holes, and fix the joints 1 together with the feeding devices on the outer wall of the shroud 4 through the clamp 3 .

[0032] Next, perform inert gas blowing and wire feeding. With a flow rate of 50 ...

Embodiment 2

[0034] The inner diameter of the joint 1 is 20 mm, the outer diameter of the metal tee pipe 2 straight pipe and the inclined pipe are both 20 mm, and the angle between the straight pipe axis and the inclined pipe axis of the metal tee pipe 2 is 120°. A two-strand slab continuous casting machine is used, the section of the slab is 1150×230 mm, and the casting speed is 1.0 m / min.

[0035] First, drilling and equipment connections are made. During the pouring process of the molten steel tank, 8 holes with a diameter of 24 mm are drilled downward in a spiral shape at a distance of 200 mm from the upper end of the shroud 4 with an electric drill, and the included angle between the axis of the holes and the axis of the shroud 4 is 50°. Insert the lower parts of the joints 1 of the 8 pre-installed feeding devices into their respective holes, and fix all the joints 1 together with the feeding devices on the outer wall of the shroud 4 through clamps 3 .

[0036] Next, perform inert ga...

Embodiment 3

[0038] The inner diameter of the joint 1 is 30 mm, the outer diameter of the straight pipe and the inclined pipe of the metal tee pipe 2 are both 30 mm, and the angle between the straight pipe axis and the inclined pipe axis of the metal tee pipe 2 is 150°. A two-strand slab continuous casting machine is adopted, the cross-section of the slab is 1150×230 mm, and the casting speed is 1.0 m / min.

[0039] During the pouring process of the steel ladle, 5 holes with a diameter of 35mm were irregularly drilled downward with an electric drill at a distance of 500 mm from the upper end of the shroud 4, and the angle between the axis of the holes and the axis of the shroud 4 was 75°. Insert the lower parts of the joints 1 of the five pre-installed feeding devices into their respective holes, and fix all the joints 1 together with the feeding devices on the outer wall of the shroud 4 through clamps 3 .

[0040] With a flow rate of 20 L / min and an air pressure of 11 atm, Ar and N are blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com