Method for applying and preparing gamma-aminobutyric acid complex compound

A technology of aminobutyric acid and copper aminobutyrate is applied in the field of application and preparation of γ-aminobutyric acid complex, which can solve the problems of active destruction of nutrients, low biological potency, large gastrointestinal irritation, etc. Small stimulation, good heating uniformity, and responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Preparation of copper γ-aminobutyric acid (the molar ratio of γ-aminobutyric acid to copper element is 1:1).

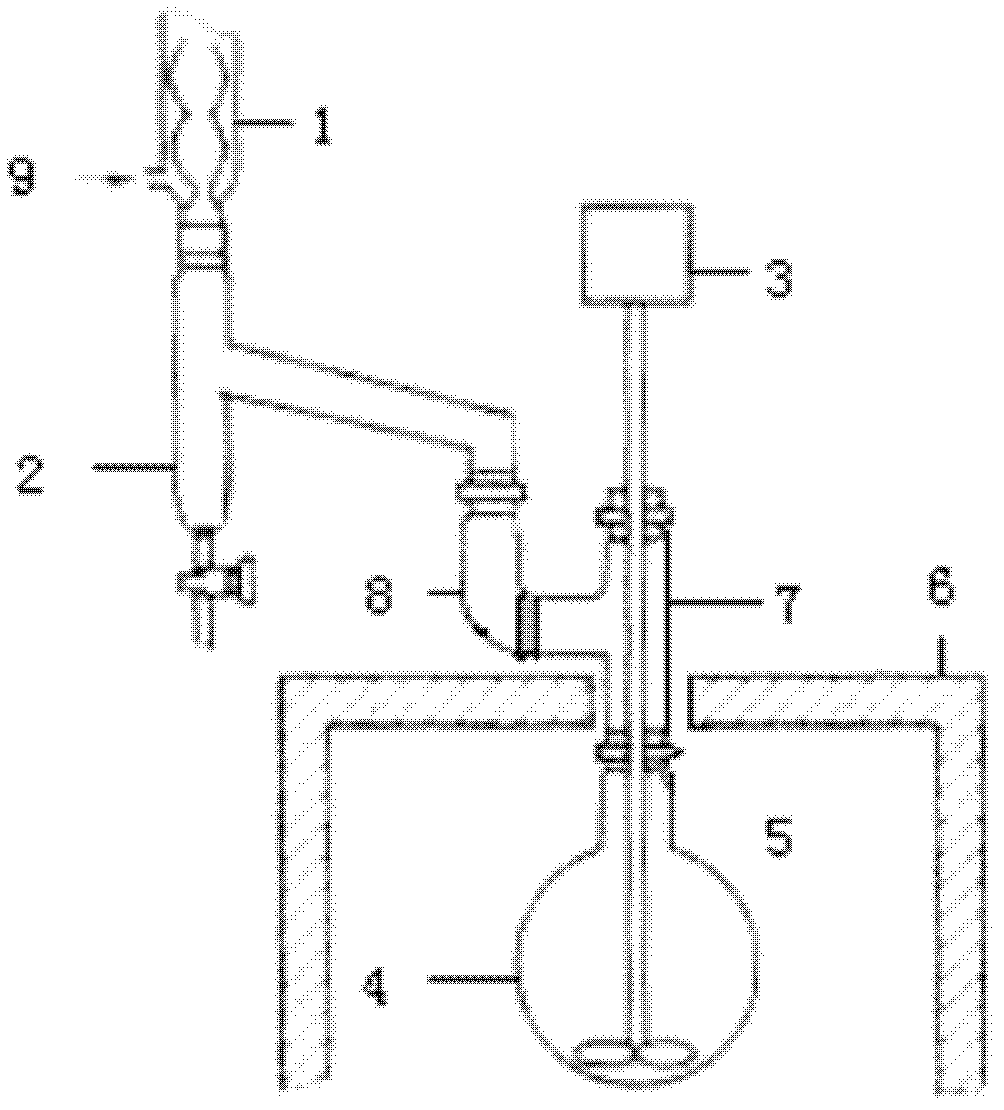

[0057] 3.4g cupric chloride dihydrate and 2.0g gamma-aminobutyric acid are added in the 50ml single-necked round bottom flask 4 of reaction device, add 20ml water as reaction bottom liquid, press figure 1 Connect the reaction device as shown (embodiments 2 to 14 are all prepared by this reaction device), and adjust the pH value of the reaction system to 4.5 with 1mol / L sodium hydroxide solution, and feed the condensate from the condensed water inlet 9 of the reaction device. water, then add the reaction bottom liquid from the upper port of the spherical reflux condenser 1 of the reaction device, until the liquid level of the reaction system reaches the glass water separator 2 (the glass water separator 2 of the reaction device passes through the adapter 8 and the ground glass After the trident tube 7 is connected to the branch pipe mouth of the singl...

Embodiment 2

[0058] Example 2: Preparation of copper gamma-aminobutyric acid (the molar ratio of gamma-aminobutyric acid to copper element is 2:1).

[0059] Add 2.5g of copper sulfate pentahydrate and 2.1g of γ-aminobutyric acid into the 25ml round bottom flask of the reaction device, add 10ml of ethanol-water solution system as the reaction bottom liquid, and adjust the pH of the reaction system with 0.5mol / L sodium carbonate solution value to 5.0, pour water into the water separator of the reaction device until the liquid level reaches the branch pipe mouth of the water separator, then turn on the stirrer for microwave heating and reflux reaction (microwave frequency is 2450MHz±50Hz, output power 80W), the whole process is controlled The pH value of the reaction system is about 5.0. When the microwave reaction is 8 minutes and 15 minutes, after taking samples in the water separator to measure the pH value, continue to add 0.5mol / L sodium carbonate solution to the nozzle of the reflux cond...

Embodiment 3

[0060] Example 3: Preparation of ferrous γ-aminobutyric acid (the molar ratio of γ-aminobutyric acid to iron element is 1:1).

[0061] Add 17.0g of ferrous sulfate monohydrate and 10.3g of gamma-aminobutyric acid into the 100ml round bottom flask of the reaction device, add 30ml of pure water as the reaction bottom liquid, and adjust the pH value of the reaction system with 1mol / L potassium hydroxide solution To 5.8, pour water into the water separator of the reaction device until the liquid level of the reaction system reaches the branch pipe mouth of the water separator, and then open the agitator to carry out microwave heating and reflux reaction (the frequency of microwave is 2450MHz±50Hz, output power 80W), The pH value of the reaction system is controlled at about 5.8 throughout the whole process. After the microwave reaction is performed every 15 minutes in the water separator to measure the pH value, continue to add 1 mol / L potassium hydroxide solution to the nozzle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com