Cathode material of secondary battery and preparation method thereof as well as anode and secondary battery

A cathode material, secondary battery technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve problems such as poor rate characteristics, inability to conduct electrons, and reduce the electronic conductivity of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of positive electrode material, comprising: a) providing Li 1+x mn y Ni z co 1-x-y-z o 2 , where 0<x<0.3, 0.5<y<0.8, 0<z<0.3;

[0033] b) the Li provided in step a) 1+x mn y Ni z co 1-x-y-z o 2 with M 2+ 、PO 4 3- The molar ratio is 1:0.03~0.07:0.03~0.07 dispersed in water to obtain a mixed solution, adjust the pH of the mixed solution to 8~9, filter and dry after stirring for 2~3 hours; wherein M is Fe, Co, Ni, Any one of Mn;

[0034] c) will be with M 2+ Li with a molar ratio of 1:1 + Mix with the solid obtained after drying in step b), and anneal at 450-550°C in air to obtain LiMPO 4 coated on the Li 1+x mn y Ni z co 1-x-y-z o 2 positive electrode material on the surface.

[0035] According to the present invention, first prepare the core material Li 1+x mn y Ni z co 1-x-y-z o 2 , wherein 01+x mn y Ni z co 1-x-y-z o 2 . Among them, the water-soluble nickel salt is preferably NiSO ...

Embodiment 1

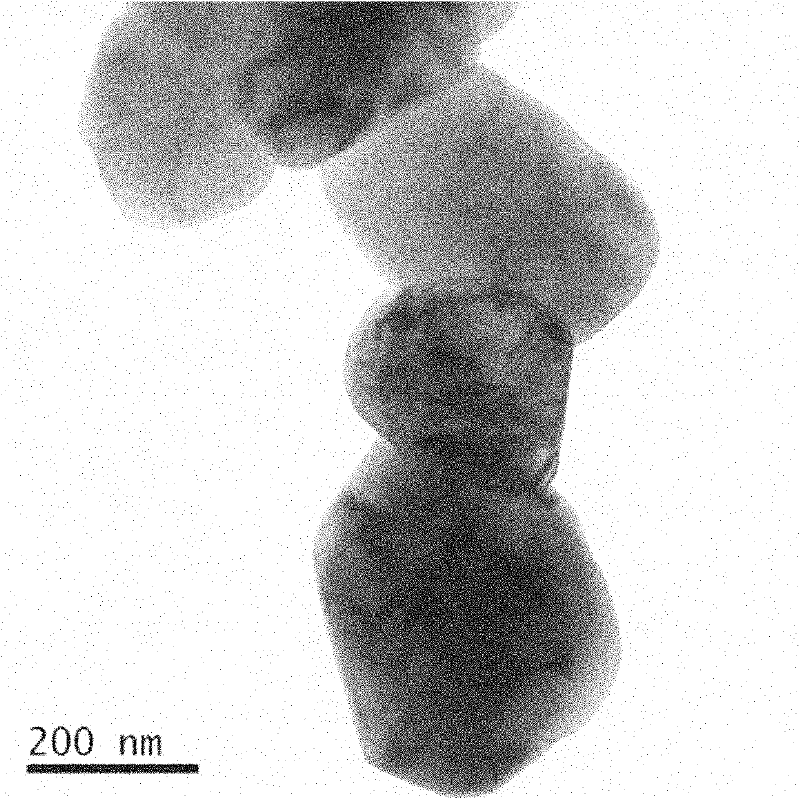

[0041] Prepare a 1mol / L aqueous solution with a Ni:Mn:Co:Li molar ratio of 0.18:0.59:0.03:1.2. The aqueous solution is transported into a drying chamber of a compressed air spray dryer through a liquid pump for spray drying to obtain dried powder. The liquid inlet speed of the spray dryer is 400mL / h, the inlet temperature is 240°C, the outlet temperature is 90°C, and the fan frequency is 45MHz. The powder was calcined in air for 2 hours at a temperature of 300°C, then raised to 900°C for 12 hours in air, and finally quenched in liquid nitrogen to obtain a solid solution material Li 1.2 Ni 0.18 mn 0.59 co 0.03 o 2 . figure 1 For the Li1.2Ni prepared in Example 1 0.18 mn 0.59 co 0.03 o 2 Electron microscope image, you can intuitively see Li 1.2 Ni 0.18 mn 0.59 co 0.03 o 2 microstructure.

Embodiment 2

[0043] Prepare a 1mol / L aqueous solution with Ni:Mn:Co:Li molar ratio of 0.25:0.52:0.1:1.13. The aqueous solution is transported into a drying chamber of a compressed air spray dryer through a liquid pump for spray drying to obtain dried powder. The liquid inlet speed of the spray dryer is 400mL / h, the inlet temperature is 240°C, the outlet temperature is 90°C, and the fan frequency is 45MHz. The powder was calcined in air for 2 hours at a temperature of 300°C, then raised to 900°C for 12 hours in air, and finally quenched in liquid nitrogen to obtain a solid solution material Li 1.13 Ni 0.25 co 0.1 mn 0.52 o 2 .

[0044] In order to further illustrate the solution of the present invention, the following are specific examples of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com