Flame retardant polypropylene composition for salivating method sheet materials and manufacture method thereof

A flame-retardant polypropylene and its manufacturing method technology, which are applied in the field of flame-retardant polypropylene composition for salivating sheet and its manufacture, can solve the problem that the flame-retardant performance of polypropylene sheet is not high, and it is difficult to meet the tearing performance and tear resistance. To solve problems such as poor crack strength, achieve the effects of easy subsequent processing and use, good electrical properties, and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

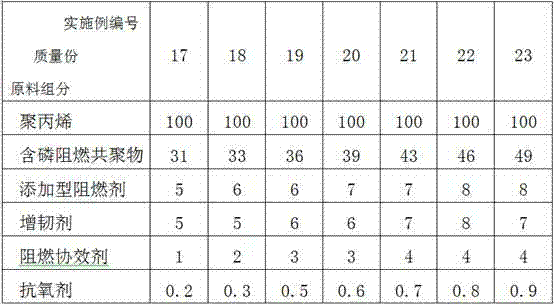

Examples

Embodiment 1

[0043] Step 1: In reactor A, mix maleic anhydride and 30% hydrogen peroxide at a mass ratio of 1:2.5, react at 40-60°C for 20 minutes, then raise the temperature to 95-100°C, stir and Under reflux, vinyl acetate was added dropwise continuously, and the addition was completed in 2 hours; the reflux reaction was kept for 2 hours and ended, and the water was removed under vacuum to obtain vinyl acetate-maleic anhydride copolymer (VAMA) for later use. The molar ratio of maleic anhydride to vinyl acetate monomer is 2:1.

[0044] Step 2: Add 600kg of DOPOMA, 1000kg of ethylene glycol, and 0.2kg of catalyst into reactor B, raise the temperature to 60-100°C under stirring, and then slowly and gradually raise the temperature to react under stirring, and the temperature rises from 100°C to 200°C for reaction After 1 hour of use, the temperature was raised to 220° C. and kept warm; 380 kg of vinyl acetate-maleic anhydride copolymer (VAMA) synthesized in the first step was added to reacto...

Embodiment 2

[0046] Step 1: In reactor A, mix maleic anhydride and 30% hydrogen peroxide at a mass ratio of 1:3, react at 40-60°C for 40 minutes, then raise the temperature to 95-100°C, stir and Under reflux, vinyl acetate was added dropwise continuously, and the addition was completed in 2 hours; the reflux reaction was kept for 2 hours and ended, and the water was removed under vacuum to obtain vinyl acetate-maleic anhydride copolymer (VAMA) for later use. The molar ratio of maleic anhydride to vinyl acetate monomer is 3:1.

[0047] Step 2: Add 700kg of DOPOMA, 1200kg of ethylene glycol, and 0.28kg of catalyst into reactor B, raise the temperature to 60-100°C under stirring, then slowly and gradually raise the temperature to react under stirring, and the temperature rises from 100°C to 200°C for reaction After 1.5 hours, the temperature was raised to 220° C. and kept warm; 580 kg of vinyl acetate-maleic anhydride copolymer (VAMA) synthesized in the first step was added to reactor B under...

Embodiment 3

[0049] Step 1: In reactor A, mix maleic anhydride and 30% hydrogen peroxide at a mass ratio of 1:3.5, react at 40-60°C for 30 minutes, then raise the temperature to 95-100°C, stir and Under reflux, vinyl acetate was added dropwise continuously, and the addition was completed in 2 hours; the reflux reaction was kept for 2 hours and ended, and the water was removed under vacuum to obtain vinyl acetate-maleic anhydride copolymer (VAMA) for later use. The molar ratio of maleic anhydride to vinyl acetate monomer is 2.4:1.

[0050] Step 2: Add 350kg of DOPOMA, 1600kg of ethylene glycol, and 0.4kg of catalyst into reactor B, raise the temperature to 60-100°C under stirring, and then slowly and gradually raise the temperature to react under stirring, and the temperature rises from 100°C to 200°C for reaction After 1.2 hours, the temperature was raised to 220° C. and kept warm; 800 kg of vinyl acetate-maleic anhydride copolymer (VAMA) synthesized in the first step was added to reactor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com