Separate type water suspension medicament of fluticasone propionate containing auxiliary materials for treating skin disease

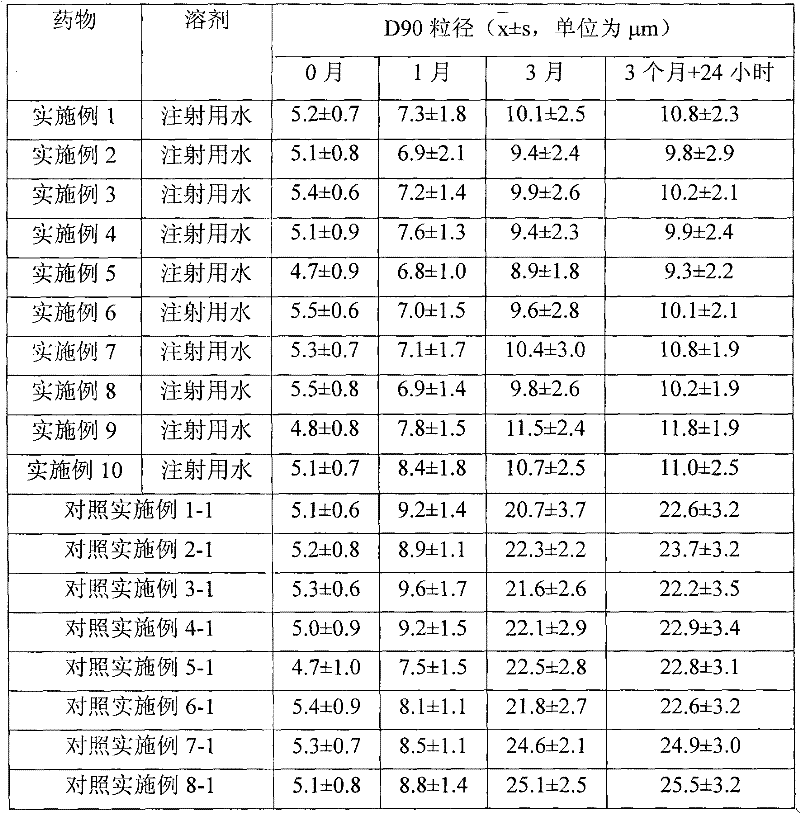

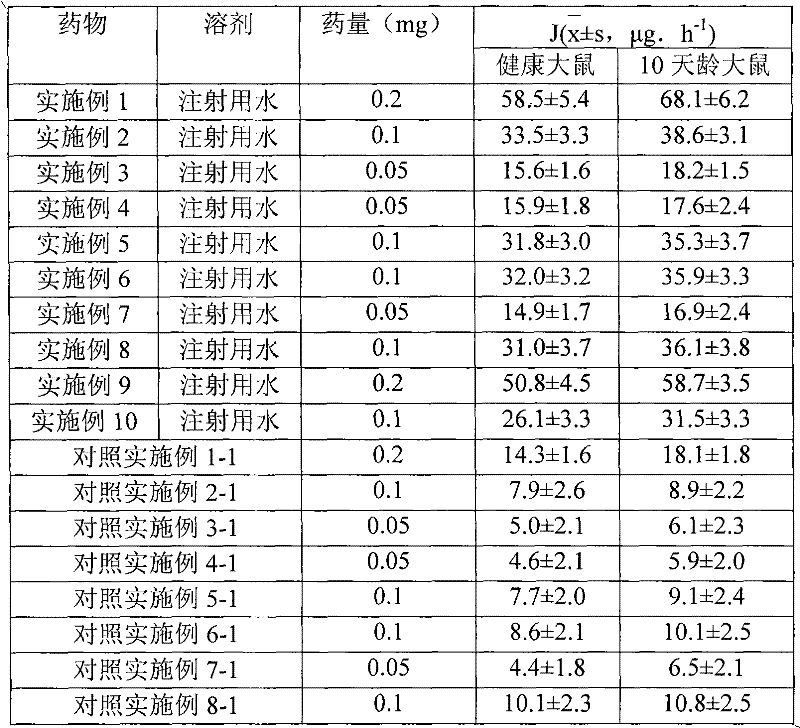

A technology for fluticasone propionate and skin diseases, which can be applied to skin diseases, drug combinations, and pharmaceutical formulations, etc. It can solve the problems of inability to guarantee the Ostwald ripening of microparticle suspensions and particle instability, and achieve waste reduction and convenience. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1. Preparation of drug particles for transdermal absorption

[0031] The capsules packed with pharmaceutical particles obtained in Examples 1 to 10 are vegetable capsules, and the capsules are sealed and packaged in glass bottles after being packed.

Embodiment 1

[0033] 0.2g of fluticasone propionate was dissolved in ethanol, filtered, sterilized, the filtrate was spray-dried, micronized to make the particle size 3μm, and mixed with 1g sodium lauroyl sarcosinate and 1.5g crystalline lactose with a particle size of 30μm. After passing through a 200-mesh sieve 3 times and mixing them, they are divided into No. 2 capsules. Each capsule contains 2 mg of fluticasone propionate. The electron microscope observed that the drug particles were spherical.

[0034] The process conditions are: inlet temperature is 100°C, outlet temperature is 70°C, air flow rate is 90%, nozzle outlet inner diameter is 0.1cm, nozzle air flow rate is 800ml / min, sampling speed is 50mL / h

Embodiment 2

[0036] Dissolve 1g of fluticasone propionate in ethanol. After filtering, the filtrate is spray-dried and micronized to a particle size of 3μm. It is mixed with 12g sodium lauroyl glutamate and 15g crystalline lactose with a particle size of 30μm. Sterilize after mixing and distribute into No. 2 capsules. Each capsule contains 1mg fluticasone propionate. The electron microscope observed that the particles were spherical.

[0037] The process conditions are: the inlet temperature is 105°C, the outlet temperature is 70°C, the air flow rate is 90%, the nozzle outlet inner diameter is 0.1cm, the nozzle air flow rate is 800ml / min, and the sampling speed is 50mL / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com