Denim clothing styling liquid, preparation method thereof, and use in ultraviolet photocatalytic styling finishing method

A technology for shaping liquid and clothing, which is applied in fiber processing, physical processing, textiles and papermaking, etc. It can solve the problems of poor hand feeling of denim clothing, affecting the durability of shaping, and shedding of shaping resin, so as to enhance the shaping effect and facilitate chemical reactions. , the effect of short setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

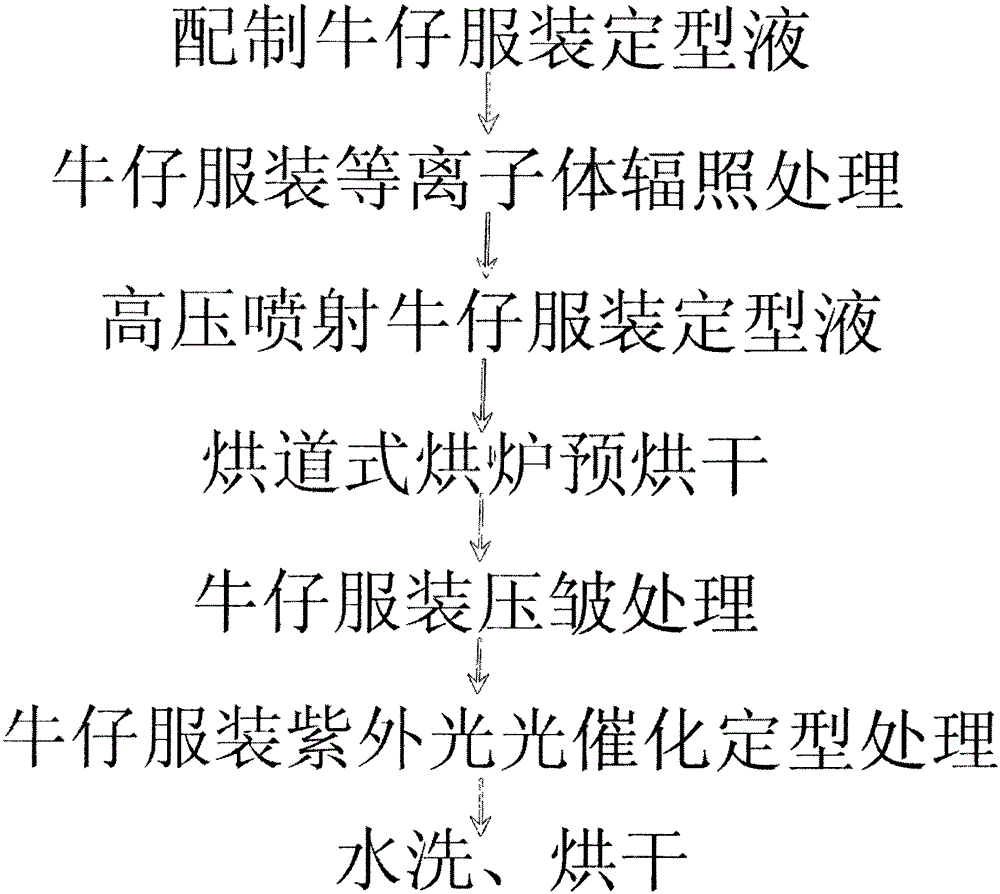

[0050] The UV photocatalytic finishing process of denim garments is: preparation of denim garment styling liquid → denim garment plasma irradiation treatment → high-pressure spray gun spraying on the denim garment required to be shaped → drying tunnel oven pre-drying → denim garment crumpling Treatment→UV photocatalytic shaping treatment→washing and drying.

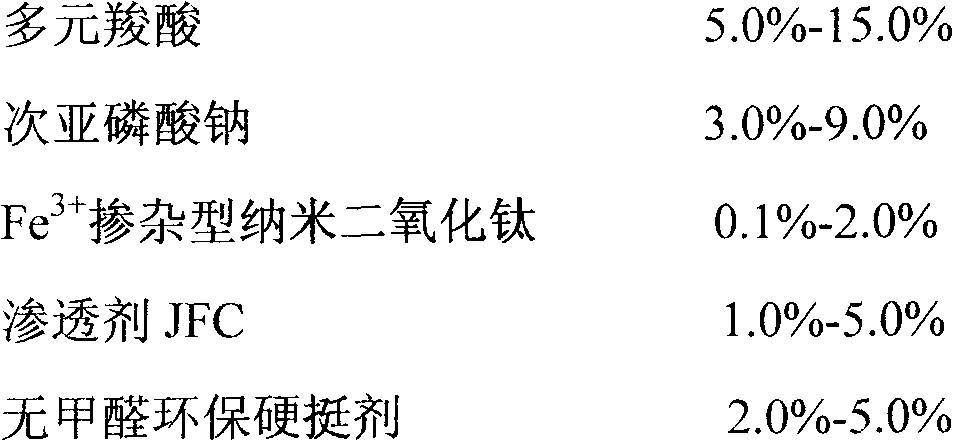

[0051] Among them, the mass percentage of denim clothing styling liquid is: butane tetracarboxylic acid 5.0%, catalyst sodium hypophosphite 3.0%, photocatalyst Fe 3+ Doped nano titanium dioxide 0.1%, penetrant JFC 1.0%, formaldehyde-free environmental protection stiffener LT-Y042.0%, smoothing brightener KW-3013.0%, water 85.9%. Denim garments require styling parts to be irradiated under a plasma device for 30s, the radiation voltage is 10kV, and the high-pressure spray gun sprays the styling liquid on the denim garments with a volume of 2kg / m 2 . The pre-drying temperature of the drying tunnel oven is 60℃, and the time is 3...

Embodiment 2

[0053] The UV photocatalytic finishing process of denim garments is: preparation of denim garment styling liquid → denim garment plasma irradiation treatment → high-pressure spray gun spraying on the denim garment required to be shaped → drying tunnel oven pre-drying → denim garment crumpling Treatment→UV photocatalytic shaping treatment→washing and drying.

[0054] Among them, the mass percentage of the denim styling liquid is: butane tetracarboxylic acid 7.5%, catalyst sodium hypophosphite 4.5%, photocatalyst Fe 3+ Doped nano titanium dioxide 0.1%, penetrant JFC3.0%, formaldehyde-free environmentally friendly stiffener LT-Y042.0%, smoothing brightener KW-3013.0%, water 79.9%. Denim garments are required to be irradiated for 60s under a plasma device, and the radiation voltage is 10kV. The amount of setting liquid used for high-pressure spray gun spraying on denim garments is 1kg / m 2 . The pre-drying temperature of the drying tunnel type oven is 60℃, and the time is 5min. The cr...

Embodiment 3

[0056] The UV photocatalytic finishing process of denim garments is: preparation of denim garment styling liquid → denim garment plasma irradiation treatment → high-pressure spray gun spraying on the denim garment required to be shaped → drying tunnel oven pre-drying → denim garment crumpling Treatment→UV photocatalytic shaping treatment→washing and drying.

[0057] Among them, the mass percentage of the denim styling liquid is: butane tetracarboxylic acid 10.0%, catalyst sodium hypophosphite 6.0%, photocatalyst Fe 3+ Doped nano titanium dioxide 0.1%, penetrant JFC 1.0%, formaldehyde-free environmental protection stiffener LT-Y042.0%, smoothing brightener KW-3013.0%, water 77.9%. Denim garments are required to be irradiated for 60s under a plasma device, and the radiation voltage is 10kV. The amount of setting liquid used for high-pressure spray guns on denim garments is 2kg / m 2 . The pre-drying temperature of the drying tunnel oven is 70℃, and the time is 3min. The crimping trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com