Steel for high-expansion-rate petroleum casing and method for manufacturing petroleum casing

A technology of oil casing and high expansion rate, which is applied in the direction of casing, drill pipe, earthwork drilling and production, etc. It can solve the problems of low actual expansion rate and high production cost, and achieve the effects of low cost, reduced production cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] High-expansion oil casing steel, the element composition raw materials are: 0.07%C, 2.0%Si, 1.2%Mn, ≤0.02%S, ≤0.02%P and the balance is Fe, and the raw materials are smelted and made steel plate.

[0023] The above-mentioned high-expansion petroleum casing steel that has been smelted and made into a steel plate is made into a seamed steel pipe by using the straight seam resistance welding manufacturing technology, and then heat-treated. The heat treatment method is to use a medium-frequency induction heater to heat to 900°C, and then use water cooling or forced air to quickly cool the seamed steel pipe to room temperature, and obtain a high-expansion seamed oil with a multiphase structure of F+M or B+a small amount of residual A. The outer diameter is 110mm and the wall thickness is 6mm. Casing, the yield strength of the obtained high-expansion slotted petroleum casing pipe reaches 380MPa, the tensile strength reaches 690MPa, and the elongation rate is 32%; The outer d...

Embodiment 2

[0025] High expansion rate oil casing steel, its elemental composition raw materials are calculated by mass percentage: 0.15%C, 1.5%Si, 1.5%Mn, 0.5%Cr, 0.05%Nb, ≤0.02%S, ≤0.02%P and the balance It is Fe, which is smelted and made into steel billets.

[0026] The above-mentioned high-expansion petroleum casing steel that has been smelted and made into steel pipe blanks is made into seamless steel pipes by using seamless pipe forming technology. Cool to room temperature to obtain a high expansion rate seamless oil casing with an outer diameter of 110 mm and a wall thickness of 6 mm with F+M or B+ a small amount of residual A multiphase structure, and the yield strength of the obtained high expansion rate seamless oil casing pipe The tensile strength reaches 400MPa, the tensile strength reaches 700MPa, and the elongation rate is 30%. The high expansion rate seamless oil casing pipe is reamed and deformed. After reaming, the outer diameter of the expanded pipe is 154mm, and the ex...

Embodiment 3

[0028] High expansion rate oil casing steel, its elemental composition raw materials are calculated by mass percentage: 0.2%C, 2.5%Si, 3.5%Mn, 0.02%Ti, 0.25%Cr, ≤0.02%S, ≤0.02%P and the balance It is Fe, which is smelted and made into steel billets.

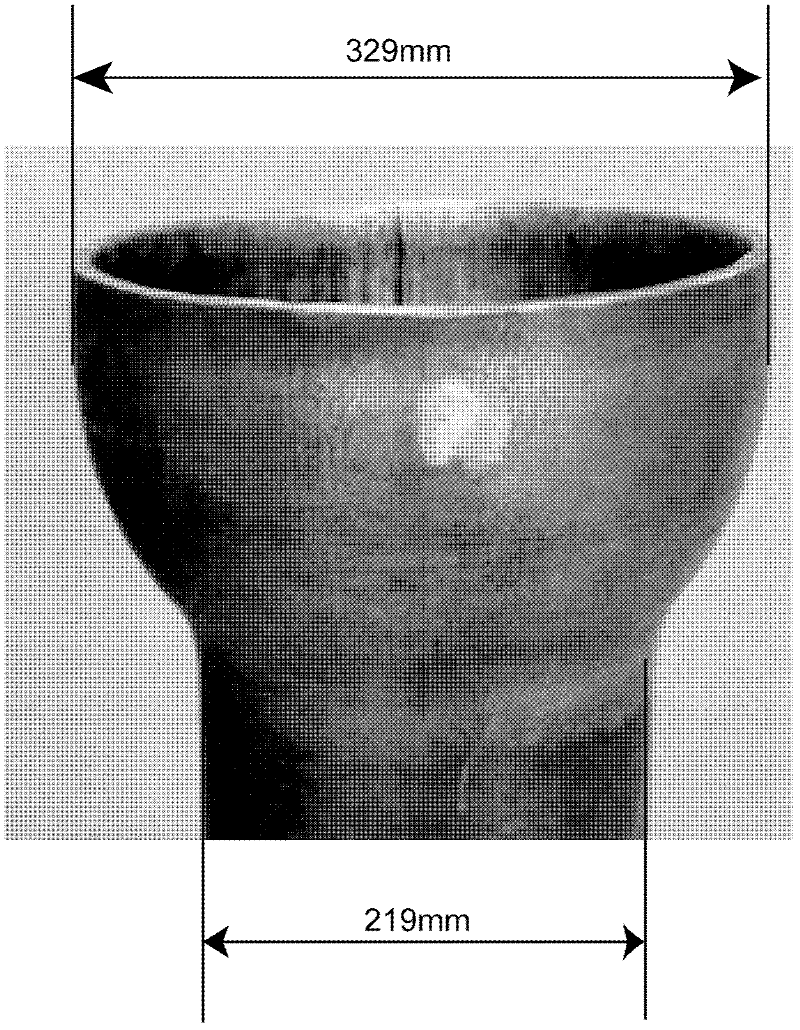

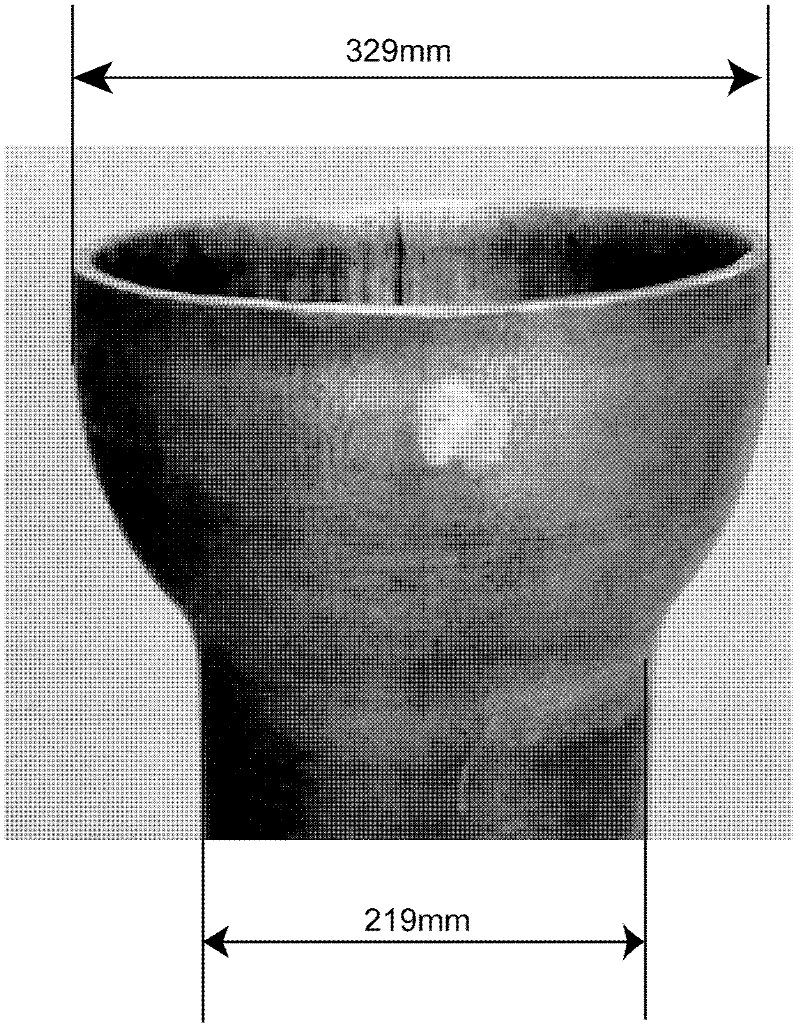

[0029] The above-mentioned high-expansion oil casing steel that has been smelted and made into steel pipe blanks is made into seamless steel pipes by seamless pipe forming technology. The temperature of the seamless steel pipes is controlled at 800 °C, and then forced air cooling is used to make the temperature of the steel pipes rapidly Cool to room temperature to obtain a high expansion rate seamless oil casing with an outer diameter of 219 mm and a wall thickness of 9 mm with F+M or B+ a small amount of residual A multiphase structure, and the yield strength of the obtained high expansion rate seamless oil casing pipe The tensile strength reaches 450MPa, the tensile strength reaches 750MPa, and the elongation rate is 30%. The hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com