Method for producing high-magnetic-induction oriented silicon steel by continuous casting and rolling of thin slab

A technology of thin slab continuous casting and high magnetic induction orientation is applied in the field of producing high magnetic induction oriented silicon steel by thin slab continuous casting and rolling. The finished product has uniform magnetic properties, good surface quality and short process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

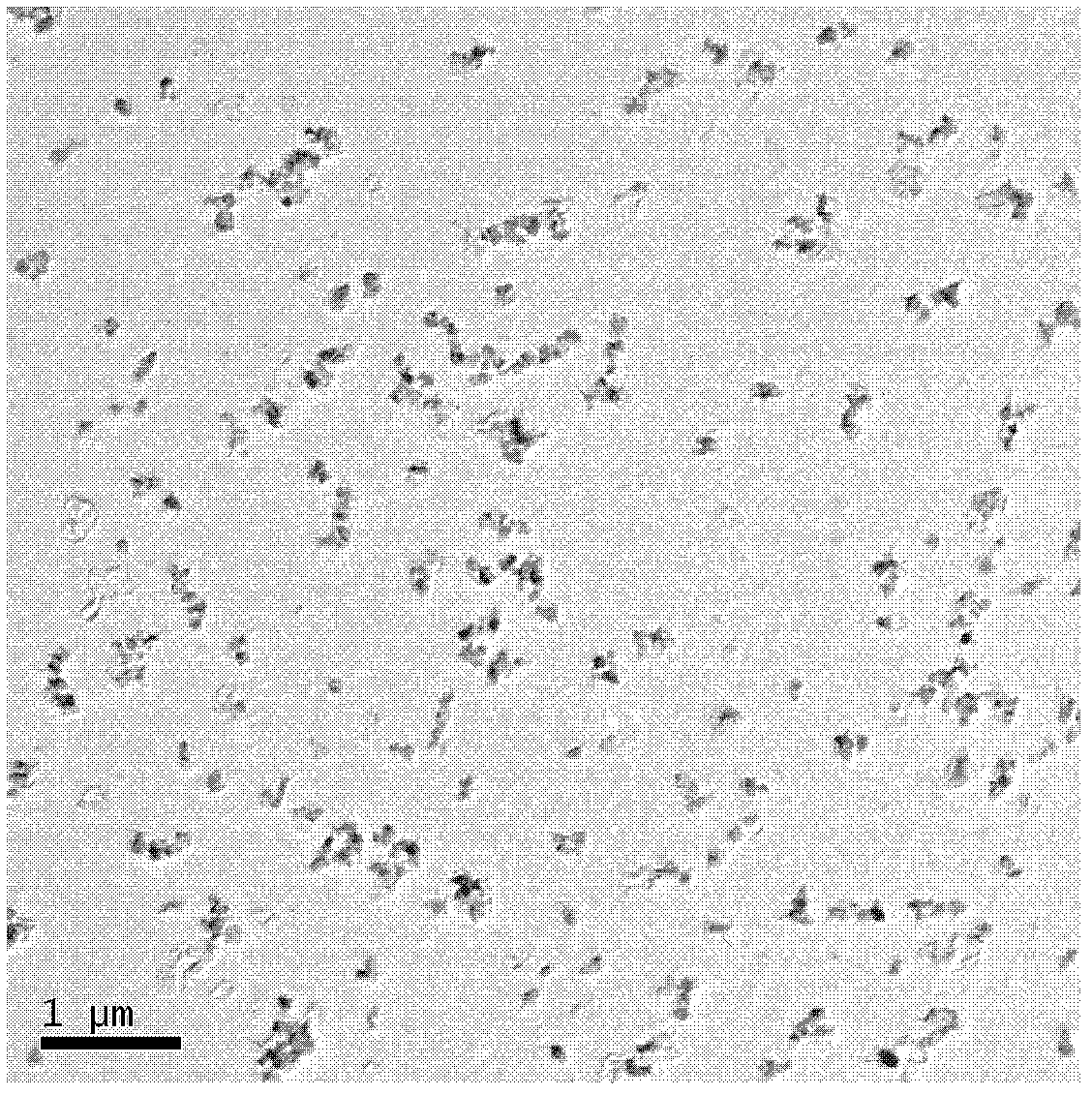

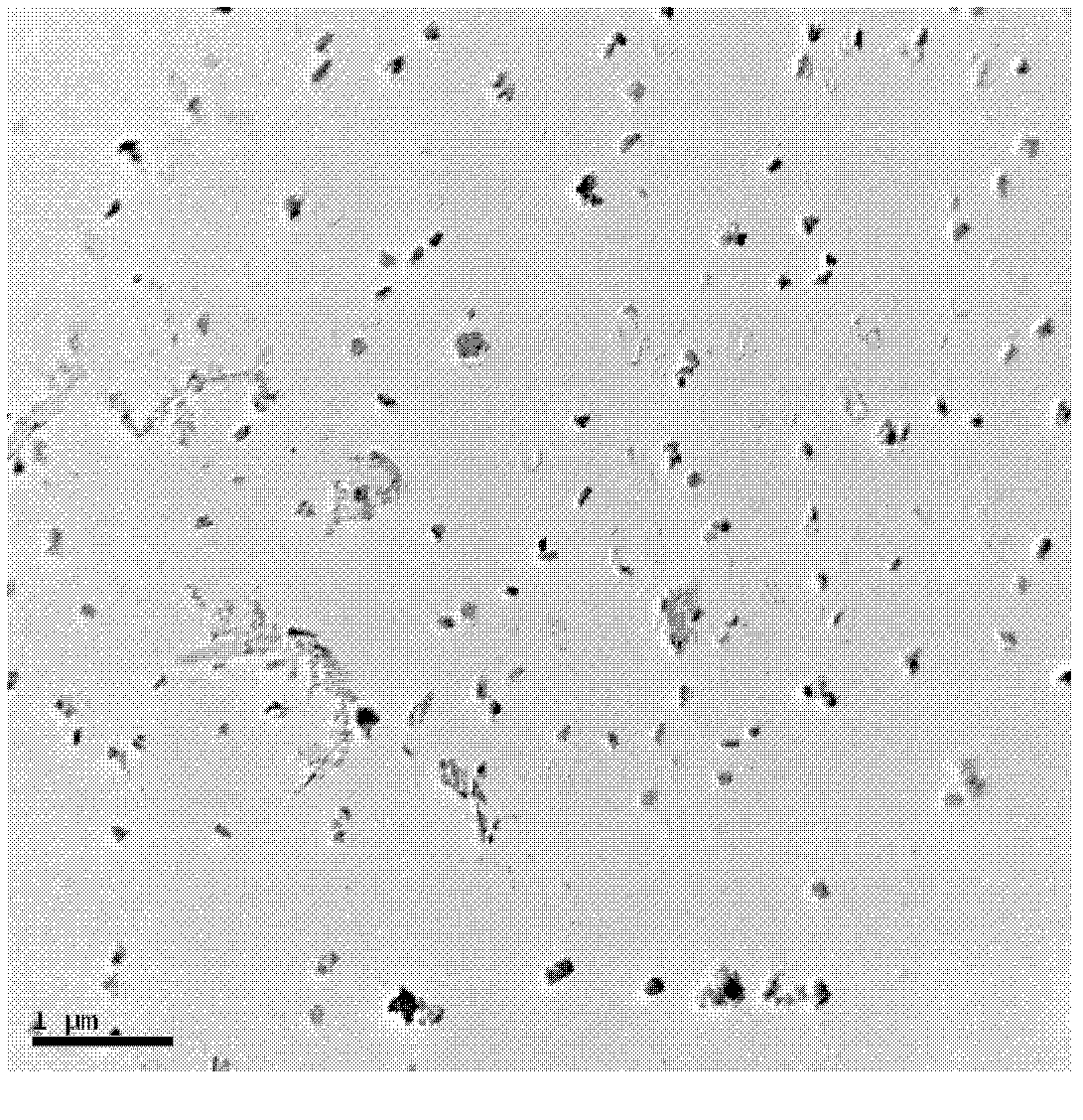

Image

Examples

Embodiment 1

[0067] This embodiment is based on the steps of the present invention. Under different steel types and product thicknesses, there are no strict requirements on the structure of the cast slab (the ratio of equiaxed grains to columnar grains), and the casting speed of the cast slab can be adjusted according to the steelmaking Aligned with the production of rolled steel.

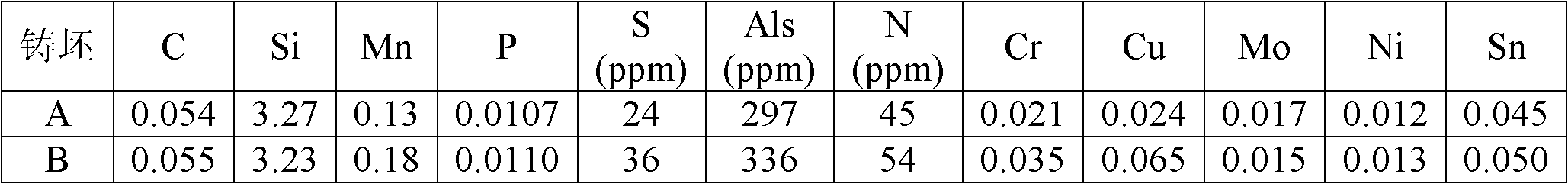

[0068] The billets A and B of the two components used in this embodiment, the corresponding chemical composition (percentage weight ratio) of the billet is shown in Table 1; wherein the steel coil of the billet A is rolled to 0.23mm and 0.27mm; Billet B is divided into B1 and B2 with different casting speeds, and the steel coils of billets B1 and B2 are rolled to 0.27mm;

[0069] The chemical composition (percent weight ratio) of table 1A and B billet

[0070]

[0071] Table 2 List of the average magnetic properties and the adhesion results of the bottom layer detected by the high magnetic induction grain-o...

Embodiment 2

[0075] The present embodiment is according to the steps of the present invention, see Table 3 and the same finished product thickness (0.27mm) under the different steel grade components, the magnetic properties, the bottom layer detected by the high magnetic induction orientation silicon steel coils produced by the C to H cast slabs Adhesion and surface quality.

[0076] Table 3 List of Steel Grade Composition of C to H Slabs

[0077]

[0078] Table 4 The magnetic properties, bottom layer adhesion and surface quality detected by high magnetic induction grain-oriented silicon steel coils produced from C to H billets

[0079] Billet

Embodiment 3

[0081] In this embodiment, according to the composition of C and G slabs in Embodiment 2, after the steel plate is pickled, it is directly rolled to thicknesses of 0.30mm, 0.27mm, and 0.23mm by one-time cold rolling. See Table 5 for its tested magnetic properties, bottom layer adhesion and surface quality.

[0082] Table 5 The magnetic properties, bottom layer adhesion and surface quality of high magnetic induction oriented silicon steel coils produced under the same composition and different thicknesses of finished products after one cold rolling

[0083] Billet

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com