1,500 KN magnetic material wet type forming hydraulic machine and hydraulic forming process

A technology of wet forming and magnetic materials, applied in the direction of forming indenter, magnetic film to substrate, etc., can solve problems such as uneven magnetization, weak magnetism, instability, etc., achieve low labor cost, enhanced magnetic field strength, The effect of guaranteed concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

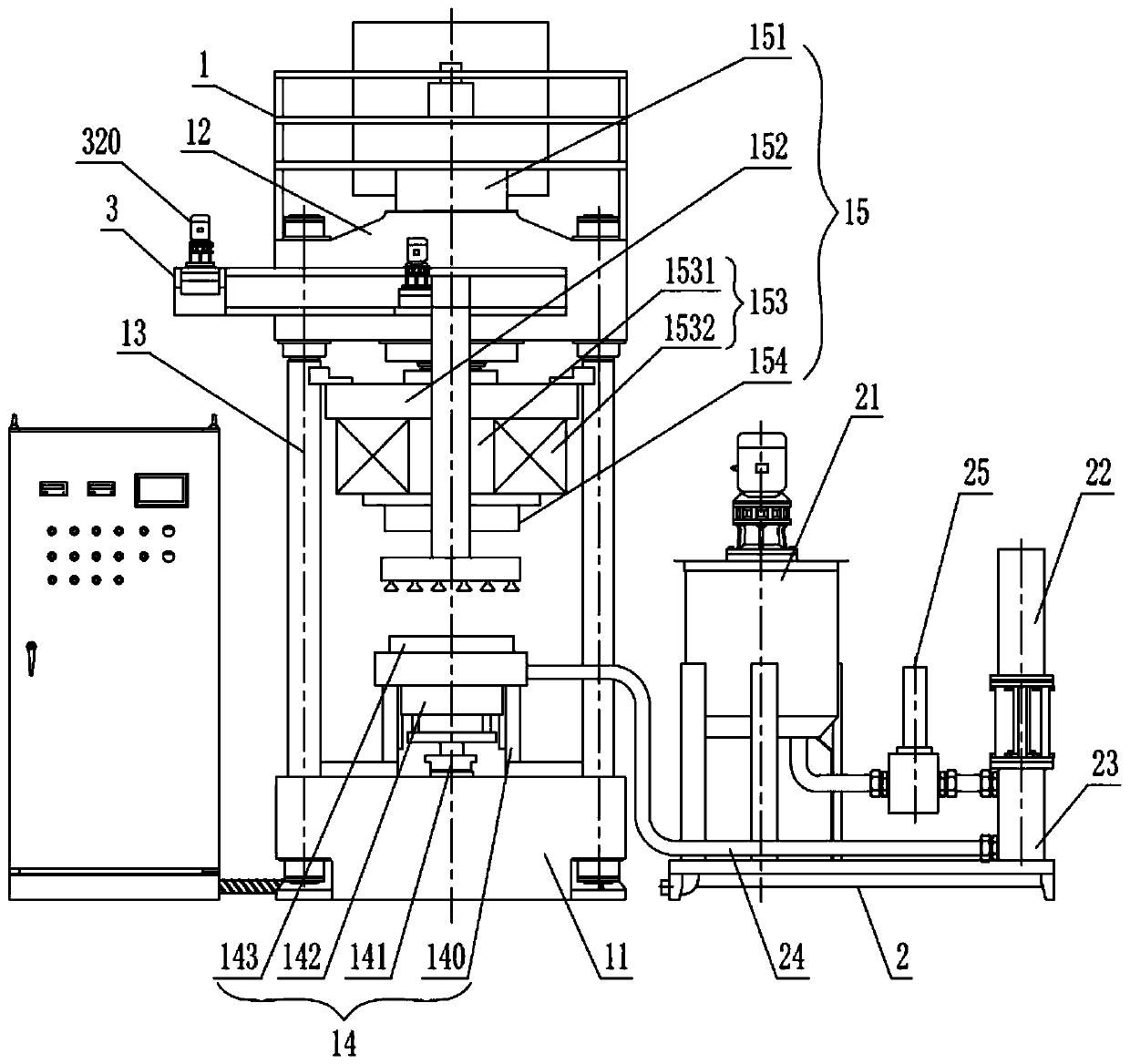

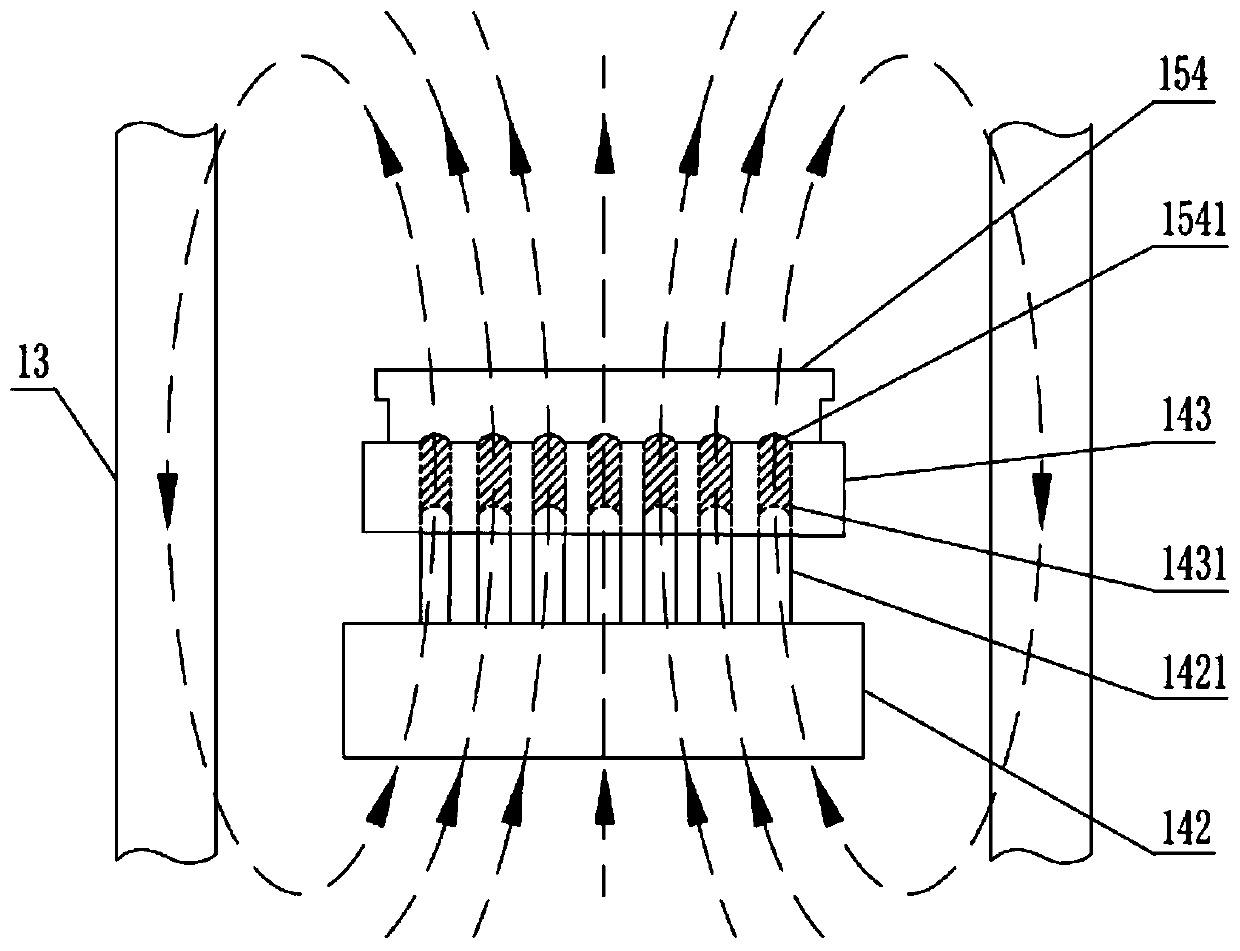

[0047] A 1500KN magnetic material wet forming hydraulic press, such as figure 1 As shown in , it includes a hydraulic machine body 1, and the hydraulic machine body 1 includes an upper workbench 12 and a lower workbench 11 co-located up and down, connected and supported by a magnetically conductive Column 13, the lower mold part 14 installed on the lower workbench 11, and the upper mold part 15 installed on the upper workbench 12; in the present embodiment, the number of the magnetic conduction columns 13 is four , distributed at the four corners of the upper workbench 12 and the lower workbench 11.

[0048] Such as figure 1 As shown in , the upper mold part 15 includes an upper slider 152 driven to slide up and down, a charging and demagnetizing device 153 fixed at the lower end of the upper slider 152, and an upper mold fixed at the lower end of the charging and demagnetizing device 153 154; an upper oil cylinder 151 is installed on the upper workbench 12, and the upper oi...

Embodiment 2

[0055] The 1500KN magnetic material wet forming hydraulic press in the present embodiment, on the basis of embodiment 1, as figure 1 As shown in , it also includes a feeding system 2, the feeding system 2 includes a pushing device 22 and a material storage cylinder 23, the pushing device 22 is arranged on the upper end of the material storage cylinder 23, and the material storage cylinder 23 It communicates with the lower mold 143 through a high-pressure injection hose 24 . In this embodiment, the material pushing device 22 is a material pushing oil cylinder, the piston rod of which extends into the material storage cylinder 23 to slide and seal with the inner wall of the material storage cylinder 23 .

[0056] When it is necessary to inject ferrite slurry into the lower mold cavity 1431, the ferrite slurry in the material storage cylinder 23 is first filled, and then the pushing device 22 is started, and the ferrite slurry in the material storage cylinder 23 Push and inject ...

Embodiment 3

[0061] 1500KN magnetic material wet forming hydraulic press in the present embodiment, on the basis of embodiment 1 and 2, such as figure 2 As shown in , it also includes a mobile pick-up device 3, the mobile pick-up device 3 includes a horizontal horizontal slide rail 31 fixed on the front side of the upper worktable 12, and a sliding bracket that is slidably connected to the horizontal horizontal slide rail 31 32, the longitudinal horizontal slide rail 33 fixed on the lower side of the sliding support 32, the vertical support 34 whose upper end is slidably connected to the longitudinal horizontal slide rail 33, and the suction cup pick-up device fixed at the lower end of the vertical support 34 35; The lower end of the sucker pick-up device 35 has several pick-up suckers 351 regularly arranged.

[0062] In this embodiment, the sliding bracket 32 is in transmission connection with the first driving device 320 arranged on the horizontal horizontal slide rail 31, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com