Hydrolysis-resistant alcoholysis-resistant nylon 66 composite material and preparation method thereof

A composite material and hydrolysis-resistant technology, which is applied in the field of modified polyamide, can solve the problems of unsatisfactory physical properties, high-precision processing, and easy destruction of hydrogen bonds, etc., and achieve long-term corrosion resistance to ethylene glycol aqueous solution. , good long-term thermal oxygen stability, and the effect of improving the interfacial bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

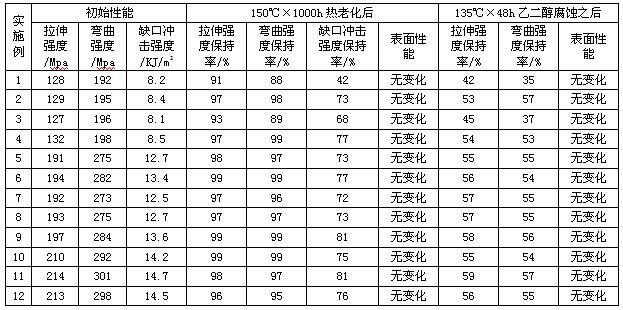

Examples

Embodiment 1

[0039]84.5kg nylon 66 (relative viscosity 2.4), 0.1kg polycarbodiimide anti-alcoholysis additive, 0.1kg copper salt composite heat stabilizer, 0.3kg talcum powder, 0.1kg montmorillonite, 0.1kg polyol The ester is added to the high-mixer, mixed evenly at room temperature and fed through the main feeder of the twin-screw extruder, 15kg of glass fiber (10μm) is fed through the side feeder of the twin-screw extruder, and then extruded through the twin-screw extruder Extrusion granulation, the processing conditions of extrusion granulation are: the temperature of the first zone is 240 ℃, the temperature of the second zone is 280 ℃, the temperature of the third zone is 280 ℃, the temperature of the fourth zone is 280 ℃, the temperature of the fifth zone is 275 ℃, the temperature of the sixth zone is 275°C, the temperature in the seventh zone is 275°C, the temperature in the eighth zone is 270°C, and the temperature in the ninth zone is 270°C; the speed of the host is 350 rpm. The re...

Embodiment 2

[0042] 83kg of nylon 66 (relative viscosity 2.4), 0.5kg of p-phenylenediamine-based alcoholysis-resistant additives, 0.3kg of copper salt composite heat stabilizer, 0.3kg of antioxidant 1010, 0.3kg of sodium benzoate, and 0.3kg of montmorillonite , 0.3kg of silicone masterbatch is added to the high mixer, mixed evenly at room temperature and fed through the main feeder of the twin-screw extruder, and 15kg of glass fiber (10μm) is fed through the side feeder of the twin-screw extruder Injection, extrusion granulation by twin-screw extruder, the processing conditions of extrusion granulation are: the temperature of the first zone is 240°C, the temperature of the second zone is 280°C, the temperature of the third zone is 280°C, the temperature of the fourth zone is 280°C, and the temperature of the fifth zone is 280°C. 275°C, the temperature in the sixth zone is 275°C, the temperature in the seventh zone is 275°C, the temperature in the eighth zone is 270°C, the temperature in the...

Embodiment 3

[0045] 82.5kg nylon 66 (relative viscosity 2.7), 1.0kg polycarbodiimide anti-alcoholysis additive, 0.3kg antioxidant 1098, 0.3kg antioxidant 168, 0.3kg sorbitol dibenzyl ester, 0.3kg mica powder, 0.3kg of polyol ester into the high mixer, mixed evenly at room temperature and fed through the main feeder of the twin-screw extruder, and 15kg of glass fiber (10μm) was fed through the side feeder of the twin-screw extruder Injection, extrusion granulation by twin-screw extruder, the processing conditions of extrusion granulation are: the temperature of the first zone is 240°C, the temperature of the second zone is 280°C, the temperature of the third zone is 280°C, the temperature of the fourth zone is 280°C, and the temperature of the fifth zone is 280°C. 275°C, the temperature in the sixth zone is 275°C, the temperature in the seventh zone is 275°C, the temperature in the eighth zone is 270°C, the temperature in the ninth zone is 270°C; the speed of the host is 400 rpm. The reside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com