Halogen-free flame-retardant and cold-resistant PC/ABS (Poly Carbonate/Acrylonitrile Butadiene Styrene) material and preparation method thereof

A technology of ABS material and ABS resin, which is applied in the field of engineering plastic modification and polymer materials, can solve the problems of poor anti-oxidation ability and anti-ultraviolet radiation ability, short service life of materials, poor impact strength ability, etc., to achieve Excellent weather resistance and low temperature impact performance, good resistance to ultraviolet radiation, and the effect of improving impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

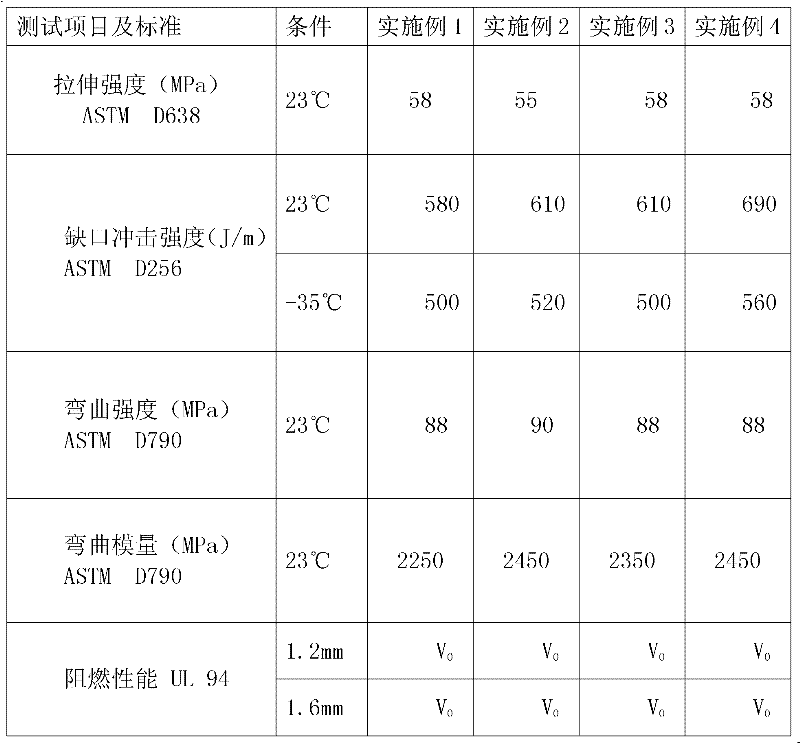

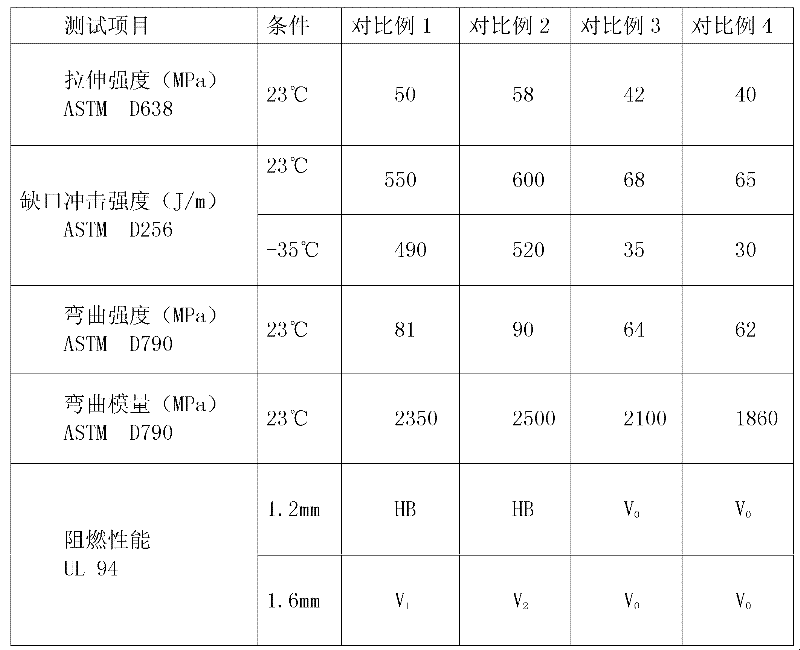

Examples

Embodiment 1

[0039] The weight ratio of PC 60.0%, ABS 25.0%, toluene xylyl phosphate 6.0%, PDMS 3.0%, MBS4.0%, toughening agent 4.0%, lubricant 0.5%, antioxidant 1.0%, anti-ultraviolet agent 0.5% Stir in a mixing barrel for 5 minutes, and then melt, extrude and granulate through a twin-screw extruder. Its processing technology is as follows: Twin-screw extruder one zone 220-230°C, two zone 235-240°C, three zone 235-240°C, fourth zone 235-240°C, five zone 240-250°C, six zone 245-250°C ℃, seven zone 240-245 ℃, eight zone 235-240 ℃; screw speed 300-450 rpm.

Embodiment 2

[0041] Mix PC 60.0%, ABS 25.0%, MPP 8.0%, PDPS 2.0%, MBS 4.0%, toughening agent 4.0%, lubricant 0.5%, antioxidant 1.0%, anti-ultraviolet agent 0.5% in the mixing tank 5 minutes, and then melted and extruded to granulate through a twin-screw extruder. Its processing technology is as follows: Twin-screw extruder one zone 220-230°C, two zone 235-240°C, three zone 235-240°C, fourth zone 235-240°C, five zone 240-250°C, six zone 245-250°C ℃, seven zone 240-245 ℃, eight zone 235-240 ℃; screw speed 300-450 rpm.

Embodiment 3

[0043] Stir the weight ratio PC 60.0%, ABS 25.0%, APP 8.0%, PDPDMS 2.0%, MBS 4.0%, toughening agent 4.0%, lubricant 0.5%, antioxidant 1.0%, anti-ultraviolet agent 0.5% in the mixing tank 5 minutes, and then melted and extruded to granulate through a twin-screw extruder. Its processing technology is as follows: Twin-screw extruder one zone 220-230°C, two zone 235-240°C, three zone 235-240°C, fourth zone 235-240°C, five zone 240-250°C, six zone 245-250°C ℃, seven zone 240-245℃, eight zone 235-240℃; screw speed 300-450 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com