Preparation method of magnesium diboride superconducting material

A superconducting material, magnesium diboride technology, applied in the direction of boron/boride, metal boride, etc., can solve the problems of inability to activate alloyed powder raw materials, small instantaneous impact force of grinding ball, short ball milling time, etc. Critical current density, improved superconductivity, low raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

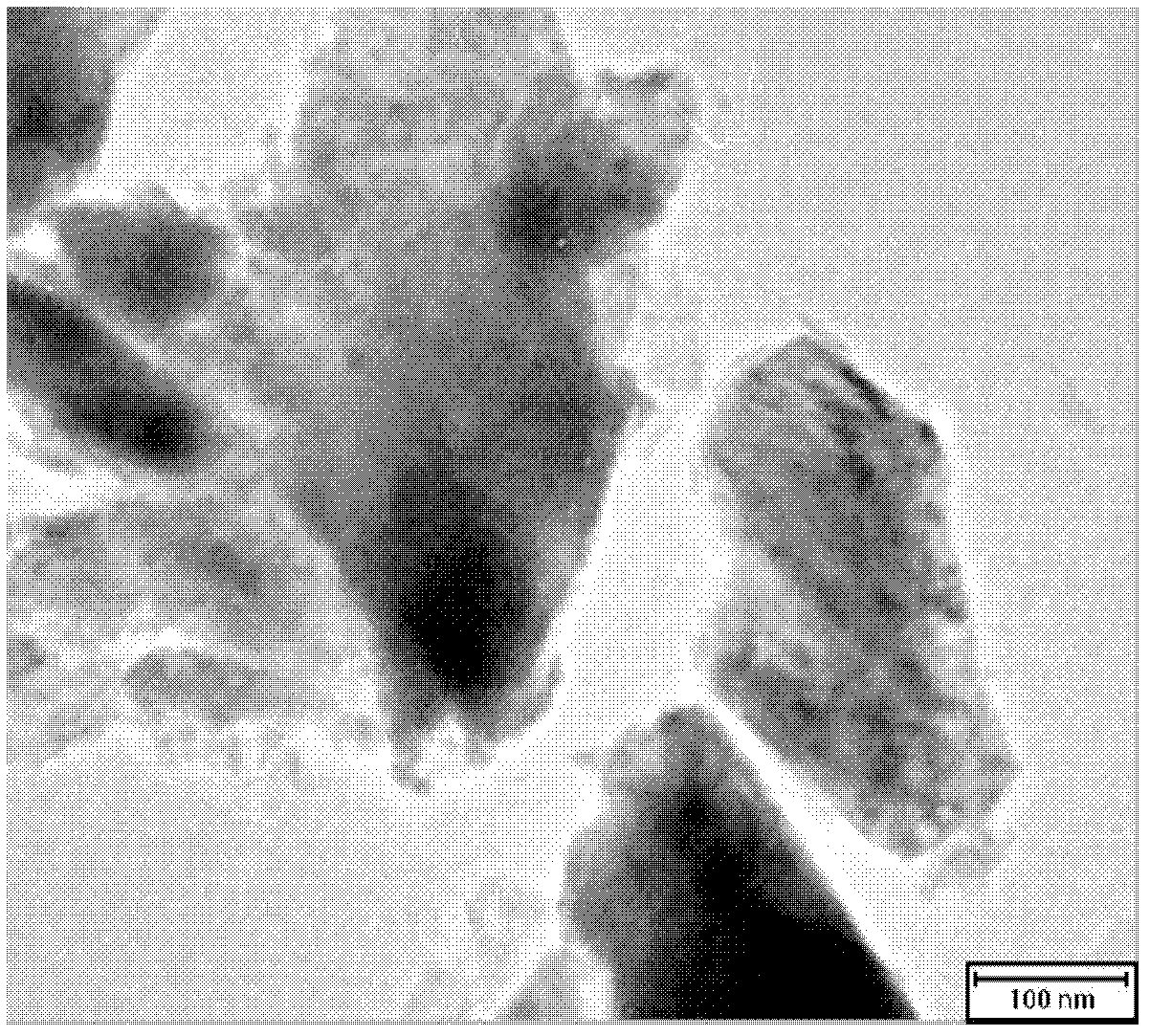

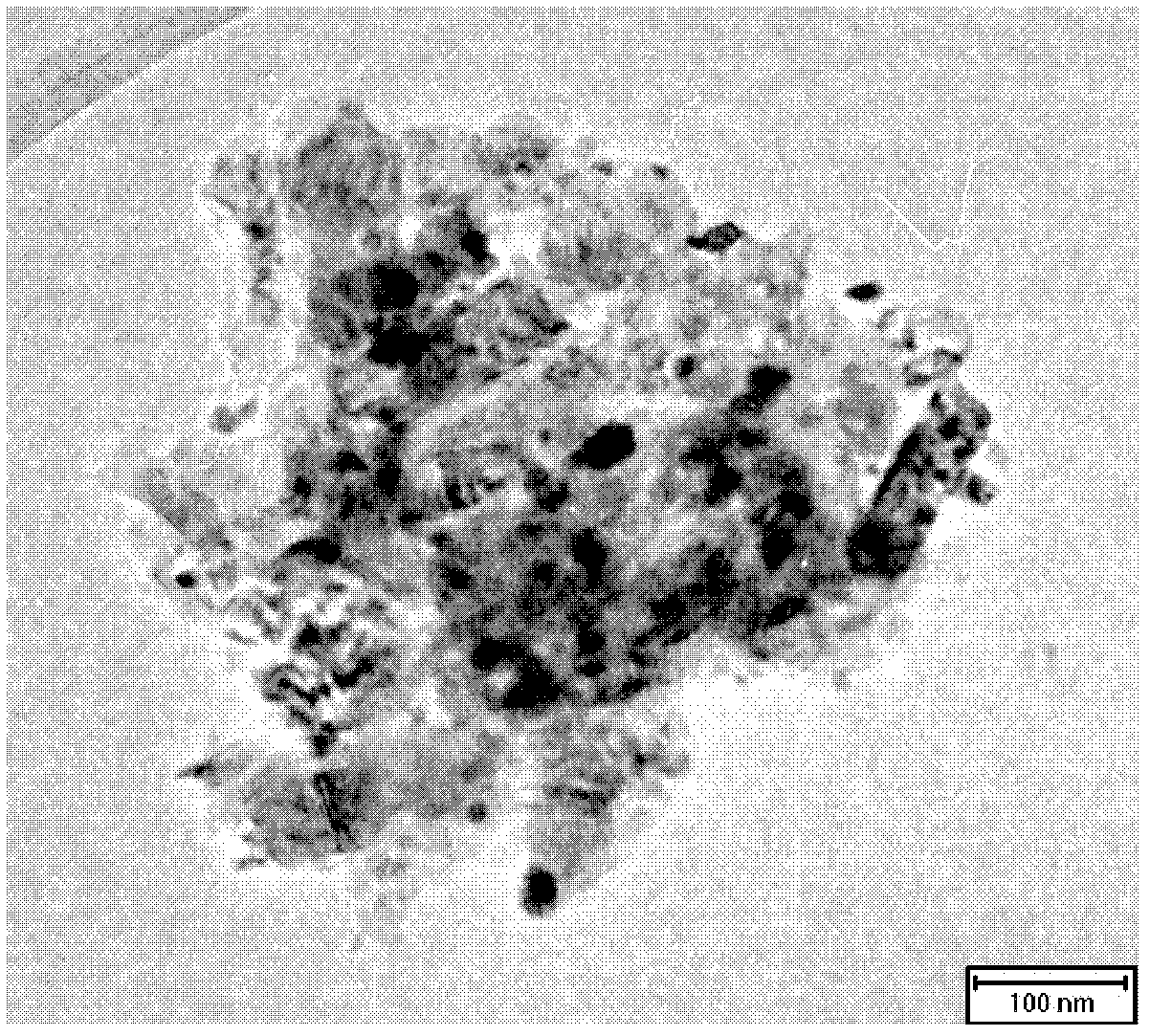

[0020] Weigh the Mg powder and the B powder according to the molar ratio Mg: B=1: 2 in the glove box with argon gas, the B powder purity is 96wt%, these raw materials are put into the tungsten carbide ball mill jar and seal, tungsten carbide mill The diameters of the balls are 5 mm and 10 mm, and the ball-to-material ratio is 64:1. Then, ball mill for 80 hours at a speed of 250r / min, put the above powder into a pure iron pipe, and after sealing, perform swaging, drawing and rolling at a deformation rate of 8% to obtain a strip of 0.5mm×4.0mm , sintered in an argon atmosphere, the sintering temperature is 700 ° C, and kept for 1 h to obtain MgB 2 superconducting tape. Such as figure 1 , figure 2 As shown, tungsten carbide ball milled for 80h to prepare MgB 2 The grain size of the sample is less than 50nm, and the agate ball milled for 30min to prepare MgB 2 The grain size of the samples exceeds 200 nm. It can be seen that MgB was prepared by long-time ball milling of tun...

Embodiment 2

[0022] Weigh the Mg powder and the B powder according to the molar ratio Mg: B=1: 2 in the glove box with argon gas, the B powder purity is 96wt%, these raw materials are put into the tungsten carbide ball mill jar and seal, tungsten carbide mill The diameters of the balls are 5 mm and 10 mm, and the ball-to-material ratio is 64:1. Then, ball mill for 80 hours at a speed of 250r / min, put the above powder into a pure iron pipe, and after sealing, perform swaging, drawing and rolling at a deformation rate of 8% to obtain a strip of 0.5mm×4.0mm , sintered in an argon atmosphere, the sintering temperature is 650 ° C, and the temperature is kept for 3 hours to obtain MgB 2 superconducting tape. Measure the critical current I of the sample with the standard four-lead method at 4.2K c With the change of the magnetic field, the quench criterion is 1μV / cm, and according to the critical current I c and MgB 2 The cross-sectional area of the superconducting core is calculated to obt...

Embodiment 3

[0024] Weigh Mg powder and B powder according to mol ratio Mg: B=1: 2 in the glove box with argon, the purity of B powder is 96wt%, measures the acetone of Mg powder and B powder gross mass 5%, will These raw materials were put into a tungsten carbide ball mill jar and sealed. The diameter of the tungsten carbide balls was 5 mm and 10 mm, and the ball-to-material ratio was 64:1. Then, ball mill for 40 hours at a speed of 250r / min, put the above powder into a pure iron pipe, and after sealing, perform swaging, drawing and rolling at a deformation rate of 8% to obtain a strip of 0.5mm×4.0mm , sintered in an argon atmosphere, the sintering temperature is 700 ° C, and kept for 1 h to obtain MgB 2 superconducting tape. Measure the critical current I of the sample with the standard four-lead method at 4.2K c With the change of the magnetic field, the quench criterion is 1μV / cm, and according to the critical current I c and MgB 2 The cross-sectional area of the superconducting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com