Preparation method of modified diatomaceous earth material for absorbing divalent copper ions in water solution

A divalent copper ion and diatomite technology, which is applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of poor stability, weak adsorption capacity, and high preparation cost. Achieve the effects of recyclable and reused adsorption materials, improved adsorption capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Using Jilin Changbai diatomite as a raw material, weigh 1g of diatomite, put it in a muffle furnace, and calcinate at 800°C for 1 hour.

[0026] 2) Dissolve 4ml of γ-aminopropyltriethoxysilane in 50ml of anhydrous toluene, mix well, add the calcined diatomite obtained in step 1), and fully stir.

[0027] 3) The obtained suspension was placed in an oil bath at 120°C, stirred and refluxed at 400 rpm for 20 hours. The resulting mixture was filtered, and the filtered solid product was subjected to three wash-filtration cycles with anhydrous toluene.

[0028] 4) Drying the solid product obtained in step 3) at 90° C., and then grinding and pulverizing it to obtain a modified diatomite product.

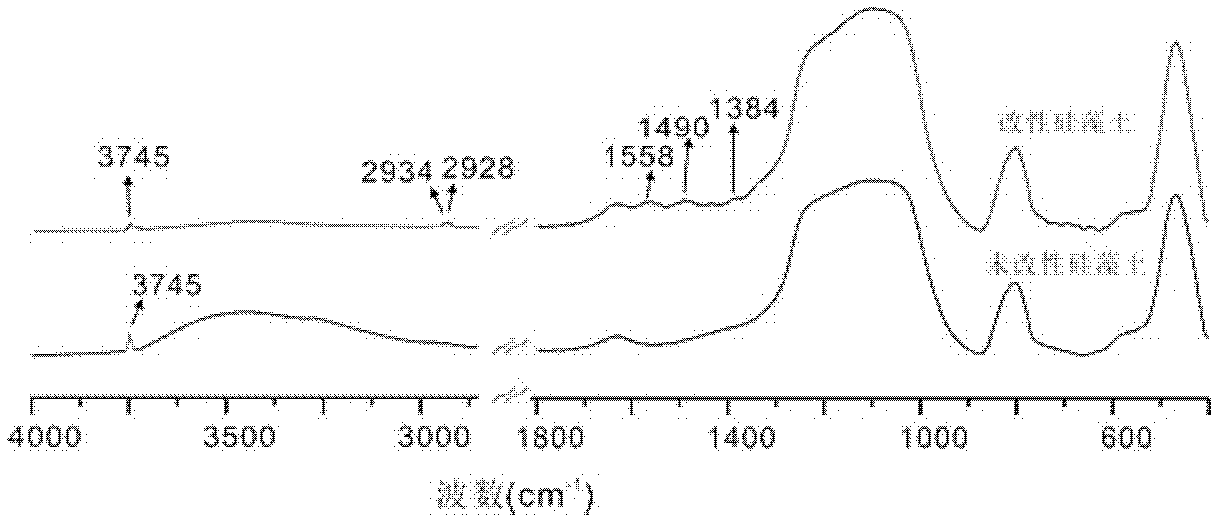

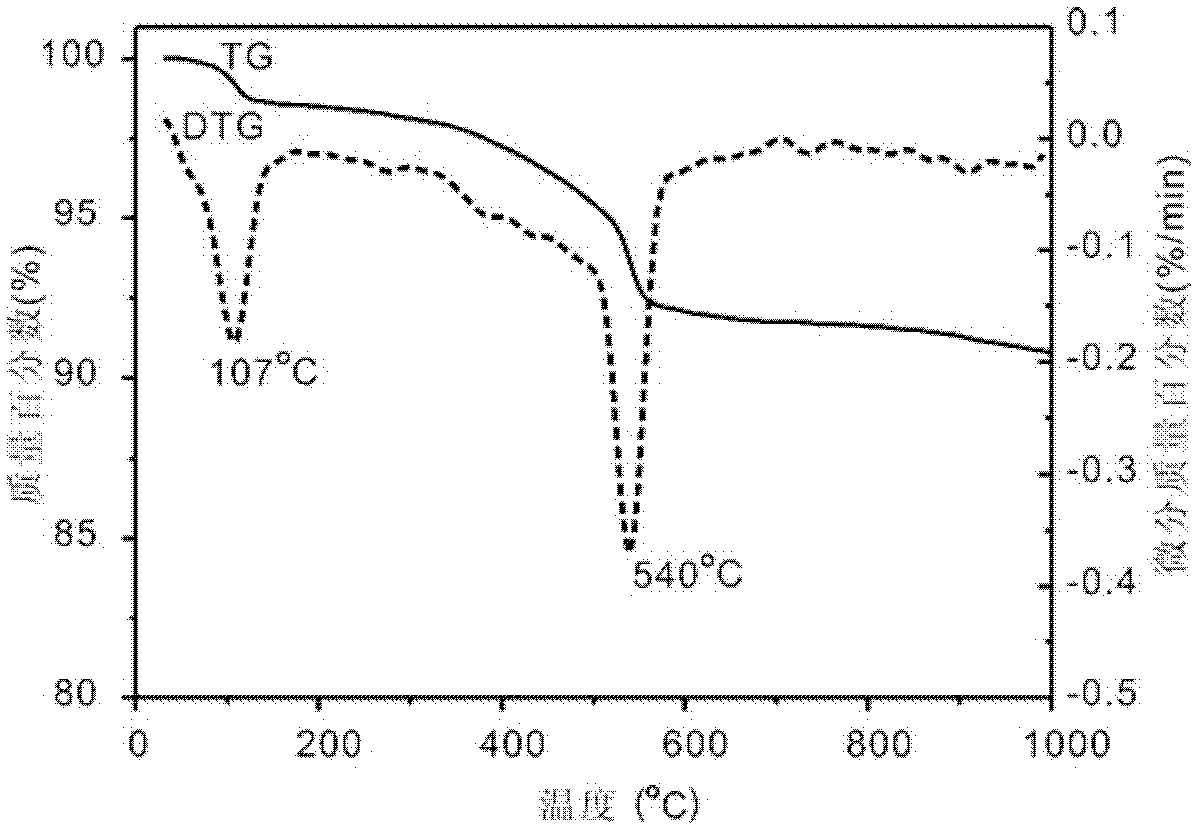

[0029] The modified diatomite was tested by means of elemental analysis, infrared spectrum analysis and thermogravimetric analysis. The results showed that the hydrolyzed γ-aminopropyltriethoxysilane was grafted on the diatomite surface (see attached figure 1 Infrared spectrosco...

Embodiment 2

[0032] 1) Using Jilin Changbai diatomite as raw material, take a 50g sample of diatomite and heat-treat it in an oven at 150°C for 24 hours.

[0033] 2) Add the heat-treated diatomite obtained in step 1) into a mixed solution of 200ml of γ-aminopropyltriethoxysilane and 600ml of anhydrous toluene, and fully stir.

[0034] 3) Stir and reflux the obtained suspension in an oil bath at 120° C. for 10 hours. The resulting mixture was filtered, and the filtered solid product was subjected to 4 wash-filtration cycles with anhydrous toluene.

[0035] 4) Drying the solid product obtained in step 3) at 90° C., and then grinding and pulverizing it to obtain a modified diatomite product.

[0036] The modified diatomite was tested by means of elemental analysis, infrared spectrum analysis and thermogravimetric analysis. The results showed that the hydrolyzed γ-aminopropyltriethoxysilane was grafted on the surface of diatomite; the grafting amount was 0.9mmol / g (according to the elemental...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com