Bearing steels

A technology of bearing steel and bearings, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve problems such as limiting steel size and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

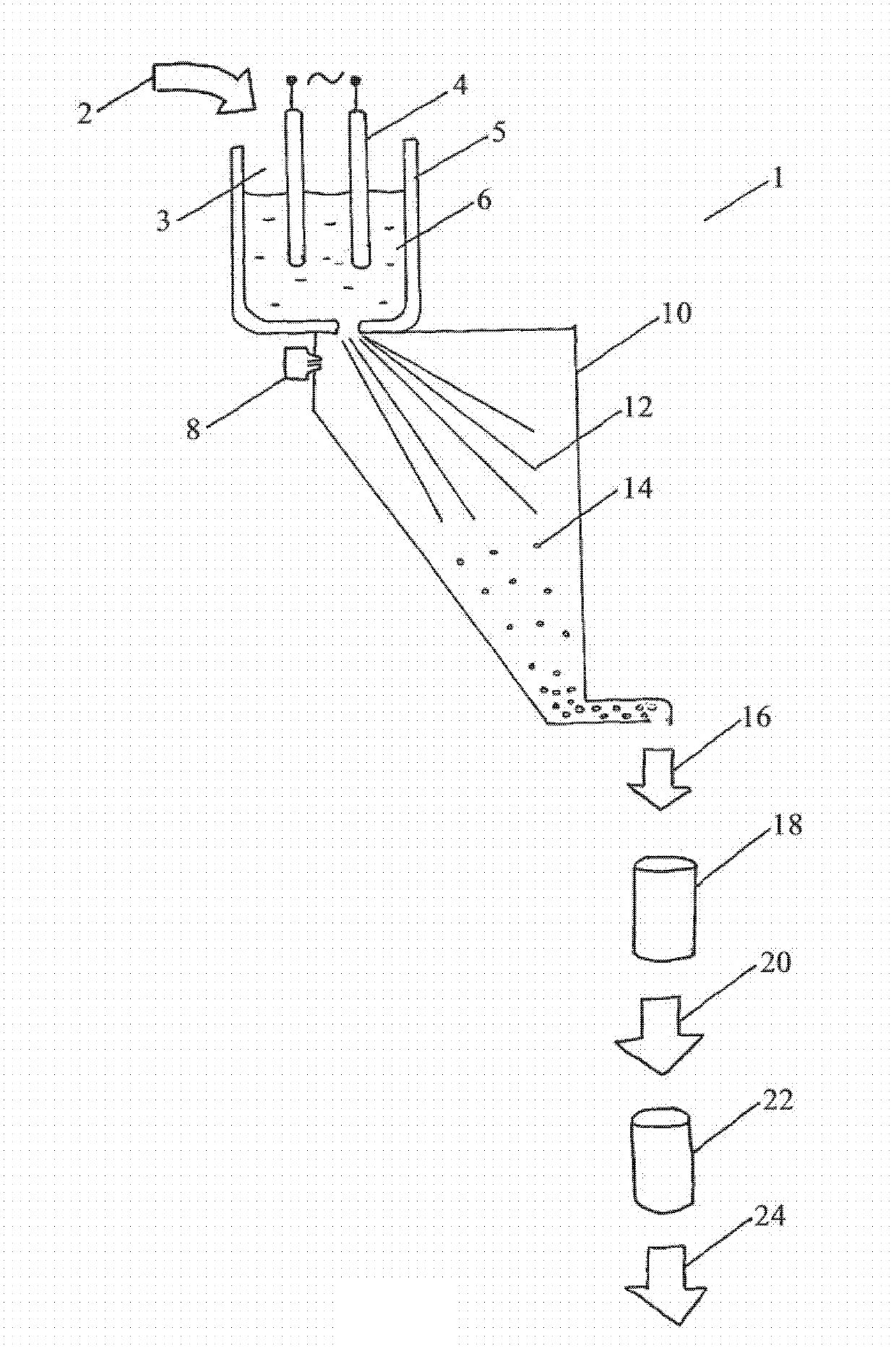

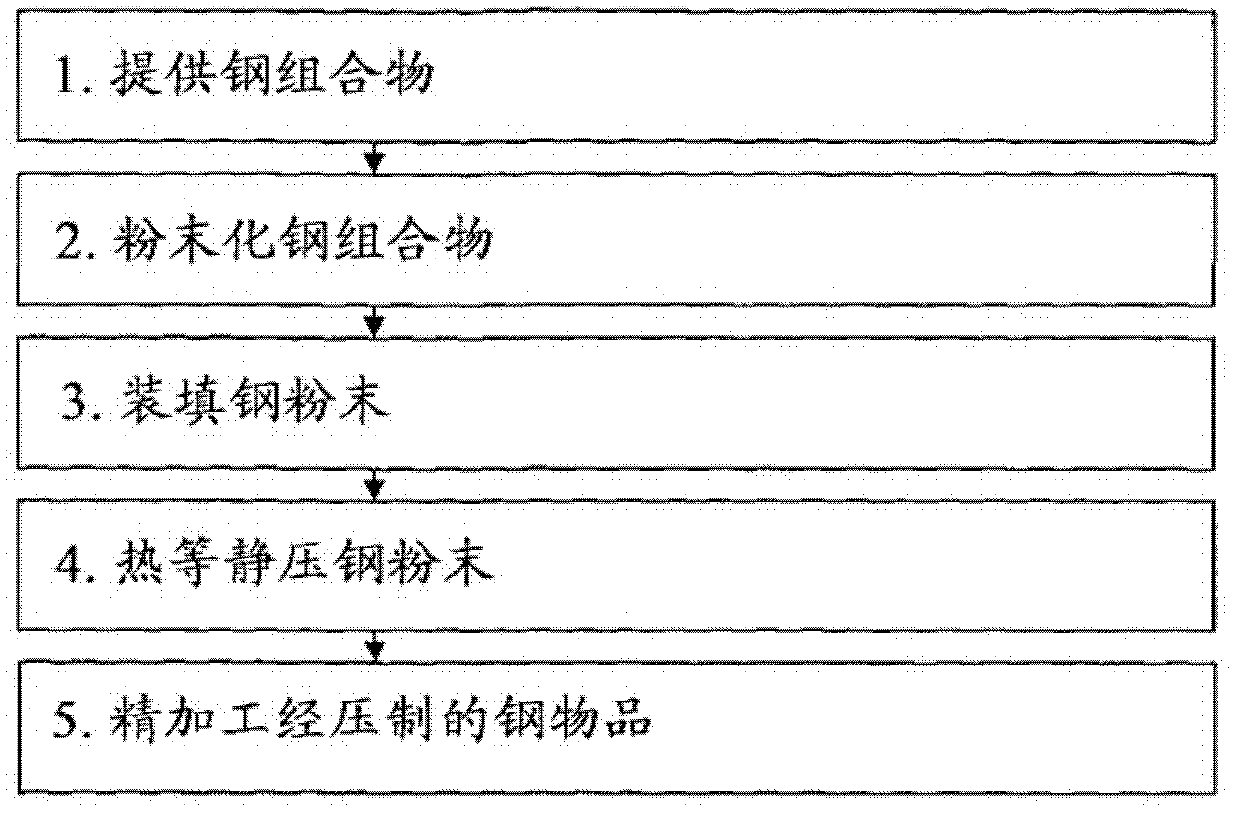

[0081] Reference now figure 1 with 2 The manufacture of stainless steel bearings is illustrated by non-limiting examples.

[0082] Such as figure 1 As shown in the steel composition 6 is prepared in an induction furnace 5. The necessary ingredients 2 to provide the desired composition are fed into the induction furnace 5. The two electrodes 4 arranged inside the induction furnace 5 are connected to an AC power source for heating the component 2 to provide a molten steel composition 6. Optionally, the molten composition 6 is kept in a tundish (not shown) under a protective atmosphere before being atomized.

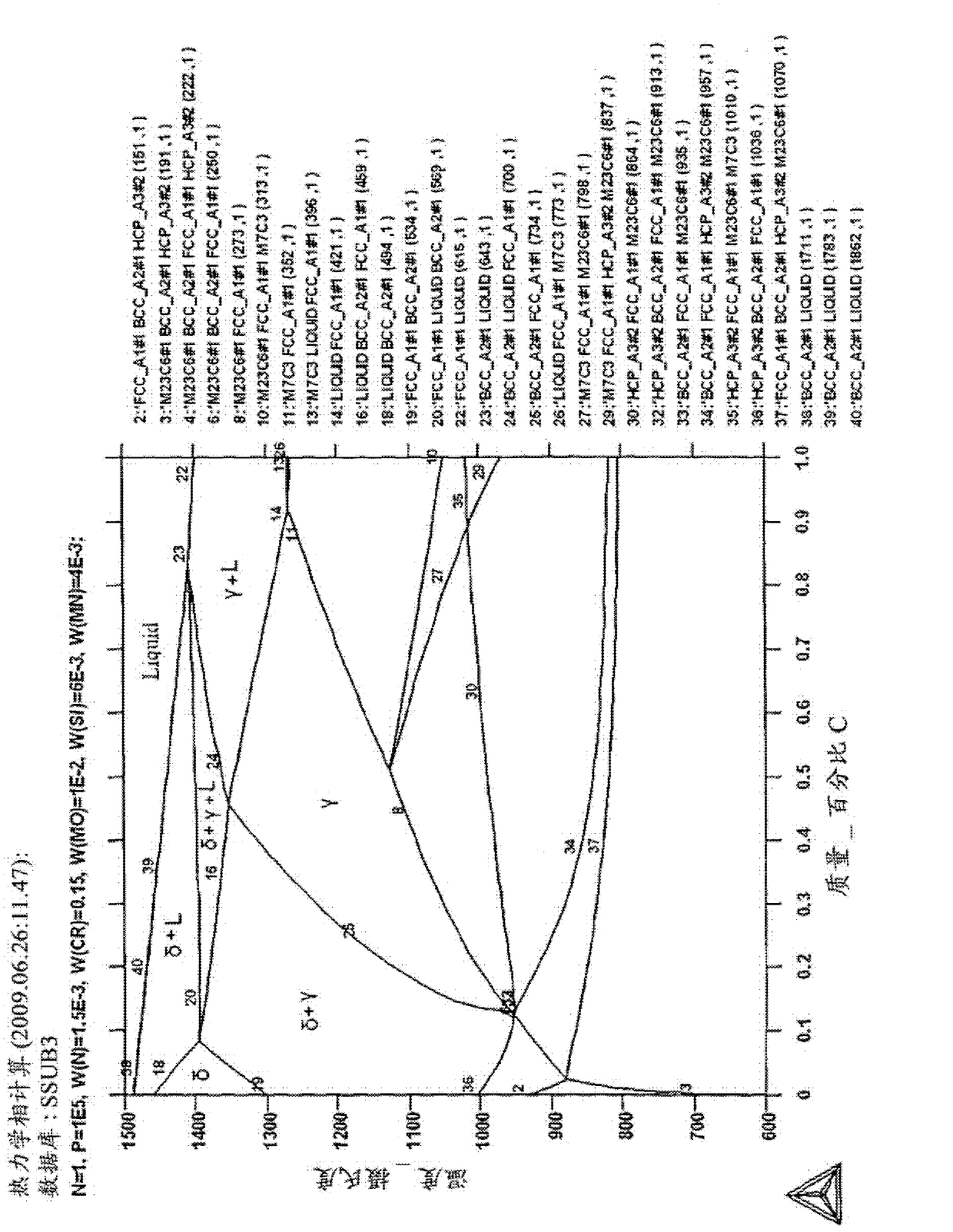

[0083] Component 2 was selected to provide the following steel composition 6.

[0084] Material

Margin

C

N

Cr

Mo

Si

Mn

Fe

aims

Fe

0.46

0.20

15

1

0.5

0.5

82.34

[0085] Table 1: All in weight%

[0086] After the steel composition 6 is completely melted, it is slowly discharged from the induction furnace 5 into the expansion chamber 10. The molten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com