NbCr2 bonded WCrRuTaV hard alloy and preparation method thereof

A cemented carbide and alloy technology, which is applied in the field of WCrRuTaV refractory high-entropy cemented carbide and its preparation, can solve problems such as difficult-to-machine materials, and achieve the effects of good performance, expansion of preparation channels, and uniform distribution of alloy components.

Inactive Publication Date: 2022-06-10

NANCHANG INST OF SCI & TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0043] Step 5) When the sample is cooled to below 100°C with the furnace, the pressure is removed and the sintered (WCrRuTaV)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

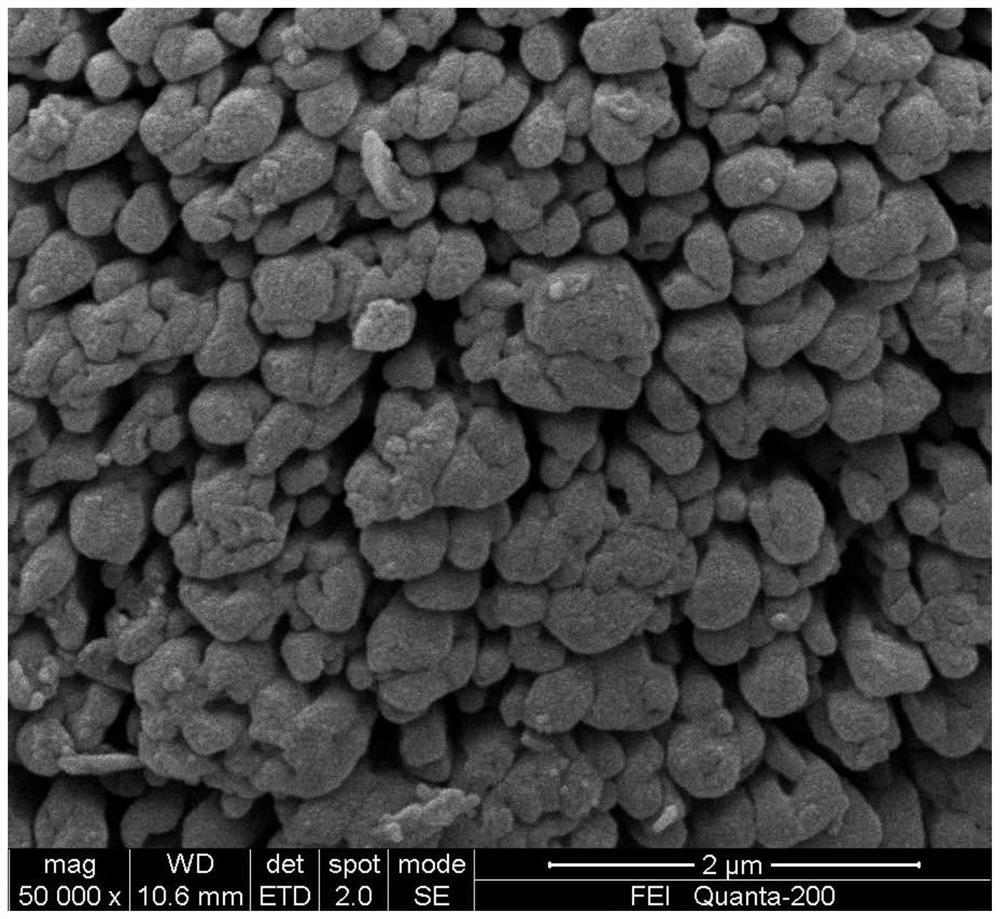

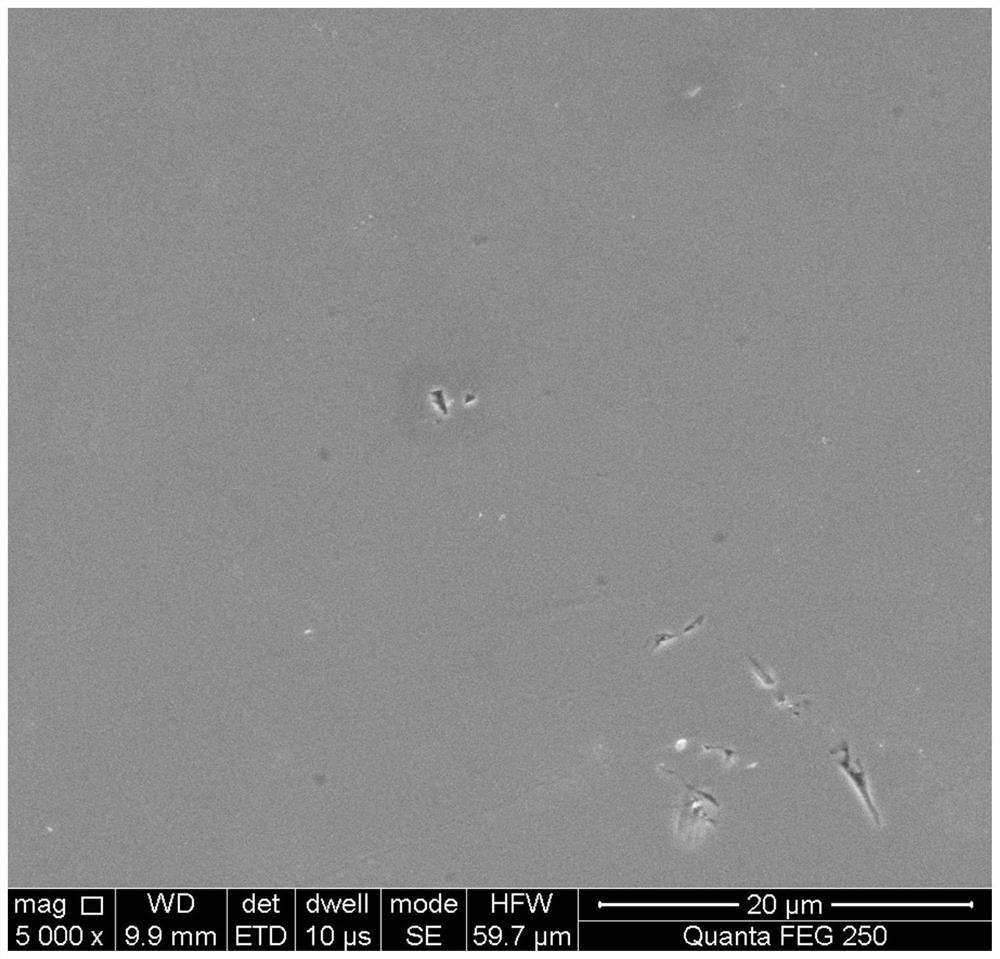

The invention discloses a WCrRuTaV refractory high-entropy hard alloy with NbCr2 as a binder and a preparation method of the WCrRuTaV refractory high-entropy hard alloy, and belongs to the technical field of hard alloy materials. Refractory metal elements W, Cr, Ru, Ta and V are adopted as raw materials, and high-entropy hard alloy powder is prepared through mechanical alloying; and the high-entropy hard alloy powder and the NbCr2 powder are evenly mixed and then subjected to spark plasma sintering, and the block hard alloy material is obtained. The NbCr2-bonded WCrRuTaV refractory high-entropy hard alloy obtained through the method has the superfine grain size and the high density, meanwhile, the hard alloy is uniform in component distribution and excellent in performance, and therefore the NbCr2-bonded WCrRuTaV refractory high-entropy hard alloy has the good application prospect.

Description

A kind of NbCr 2 Bonded WCrRuTaV cemented carbide and preparation method technical field The present invention relates to the technical field of cemented carbide materials, specifically a kind of NbCr 2 Bonded WCrRuTaV Refractory High Entropy Cemented carbide and preparation method thereof. Background technique Cemented carbide is mainly a kind of wear-resistant alloy material with higher hardness and strength, which is widely used in machinery manufacturing. In the processing industry, it is mainly used to make cutting tools, wear-resistant parts and molds. However, in recent years, with some difficult-to-machine materials The development of the material and machining industry has put forward higher requirements for the high temperature performance of cemented carbide tools under complex working conditions. beg. Refractory metals usually refer to tungsten, molybdenum, niobium, tantalum, vanadium, zirconium, etc., with refractory, good high temperature stre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C1/04C22C30/00B22F3/105B22F9/04

CPCC22C1/04C22C30/00B22F9/04B22F3/105B22F2009/043B22F2003/1051

Inventor 聂小武盛明强马比阿伟余强韩亚平

Owner NANCHANG INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com