A method for preparing Aln nano-powder by plasma-assisted high-energy ball milling

A technology of high-energy ball milling and plasma, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of large dislocation defects, high grain internal energy, high conversion rate, etc., and meet the requirements of reducing high temperature resistance and reducing Composite temperature, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

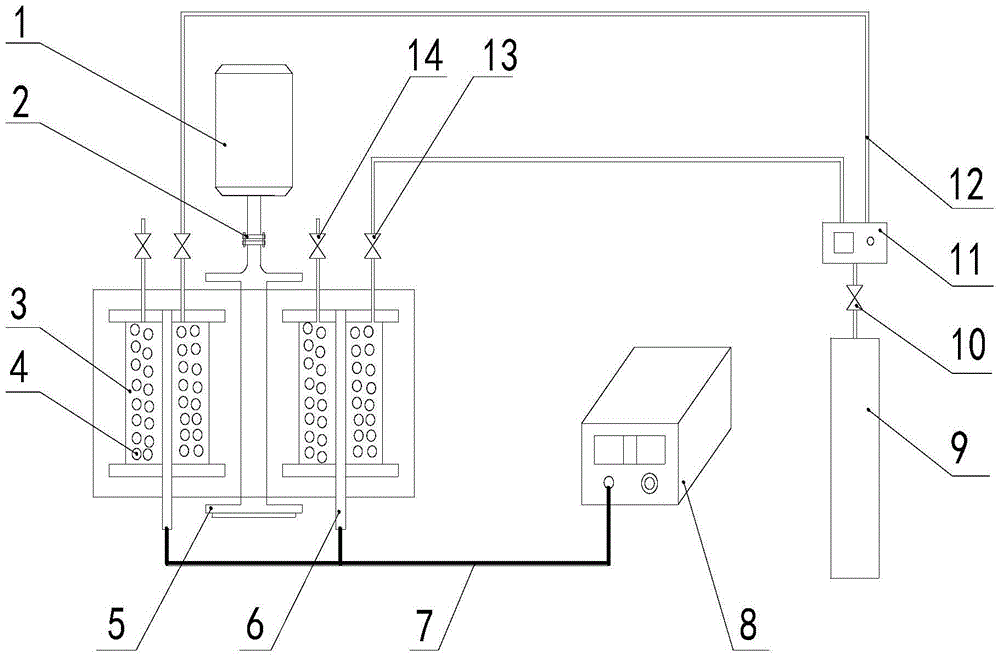

Image

Examples

Embodiment 1

[0030] Weigh 150g of alumina with a purity of 99.99% and a particle size of 20um. According to the ratio of ball to material ratio of 50:1, put it into a cleaned high-energy ball mill. Under the protection of nitrogen, it is cooled by circulating water and the peak AC voltage is 45kV. , Frequency 8000Hz, ball milling 0-40h, high-energy ball mill rotation 1400rpm, the temperature of the high-energy ball mill tank during the ball milling process is controlled below 50 ℃.

[0031] The ball-milled alumina and carbon black are mixed in a mass ratio of 1:0.6 and put into a high-temperature heating furnace, and the reaction temperature is 1100-1600°C. The holding time was 4h, the atmosphere was circulating nitrogen, and the gas flow was 100ml / min. Then naturally cooled to room temperature.

[0032] After the reaction at different temperatures, put the powder into a clean crucible, and put it into a muffle furnace and heat it in the air at 1000°C, hold it for 4 hours, and then slowly...

Embodiment 2

[0033] Embodiment 2 is the embodiment of adding carbon black during reaction:

[0034] Weigh 150g of alumina with a purity of 99.99%, mix alumina and carbon black at a mass ratio of 1:1, and put it into a cleaned ball mill in a ball-to-material ratio of 50:1. Under the protection of nitrogen, circulate Water cooling, AC peak voltage 45kV, frequency 8000Hz, ball mill 0-40h, ball mill revolution 1400rpm, the temperature of the ball mill tank during the ball milling process is controlled below 50 ℃.

[0035] The ball-milled alumina and carbon black mixed powder is put into a high-temperature heating furnace, and the reaction temperature is 1100-1600 °C. The holding time was 4h, the atmosphere was circulating nitrogen, and the gas flow was 100ml / min. Then naturally cooled to room temperature.

[0036] After the reaction at different temperatures, put the powder into a clean crucible, and put it into a muffle furnace and heat it in the air at 1000°C, hold it for 4 hours, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com