Carbon-fiber-based amorphous Pb-Mn-RuOx gradient anode material for manganese electrodeposition and preparation method

An anode material and carbon fiber technology, applied in electrodes, electrolytic coatings, metal material coating processes, etc., can solve the problems of expensive titanium-based coatings, poor conductivity of electrode plates, large one-time investment, etc. The production of mud, the improvement of binding force, and the good effect of chlorine corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

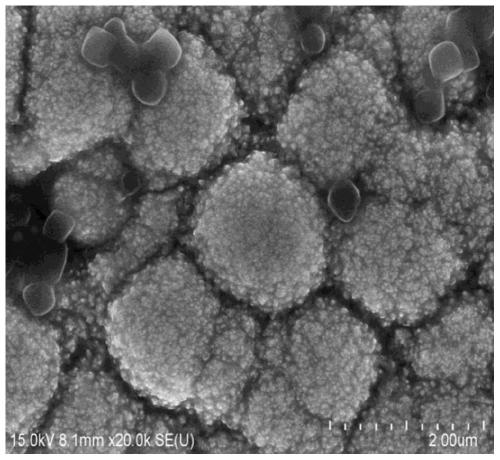

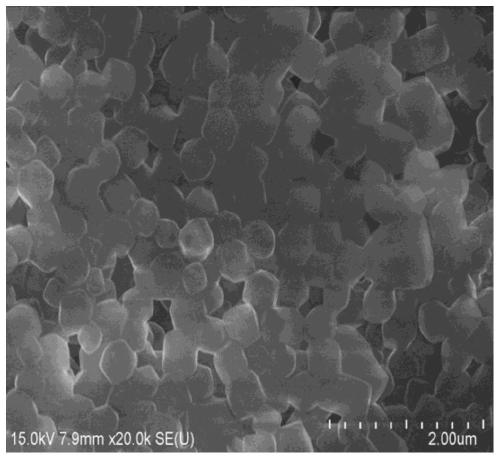

[0029]The carbon fiber-based amorphous Pb-Mn-RuO gradient anode material of the present embodiment is made of carbon fiber substrate, Ni-Co coated on the carbon fiber substrate 3 o 4 The bottom layer, the Sn-Co-RuOx intermediate layer covering the bottom layer, and the amorphous Pb-Mn-RuOx active layer covering the Sn-Co-RuOx intermediate layer. The Ni-Co 3 o 4 The bottom layer is a composite coating, and the Co in the composite coating 3 o 4 The composition is 2.85-10wt%, and the Sn:Co:Ru molar ratio in the middle layer, that is, the Sn-Co-RuOx coating is (54-80):(18-32):(1-10); amorphous Pb-Mn - The molar ratio of Pb:Mn:Ru in the RuOx active layer is (42-70):(24-48):(2-12).

[0030] The preparation method of the carbon fiber-based amorphous Pb-Mn-RuO gradient anode material of the present embodiment, the specific steps are as follows:

[0031] (1) Pretreatment of the carbon fiber matrix: firstly remove the glue, and heat the carbon fiber matrix at 400-800°C under the p...

Embodiment 2

[0037] The carbon fiber-based amorphous Pb-Mn-RuO gradient anode material of the present embodiment is made of carbon fiber substrate, Ni-Co coated on the carbon fiber substrate 3 o 4 The bottom layer, the Sn-Co-RuOx intermediate layer covering the bottom layer, and the amorphous Pb-Mn-RuOx active layer covering the Sn-Co-RuOx intermediate layer. Among them, Ni-Co 3 o 4 Co in the composite coating 3 o 4 The composition is 8wt%, the Sn:Co:Ru molar ratio in the Sn-Co-RuOx coating is 60:28:10; the Pb:Mn:Ru molar ratio in the amorphous Pb-Mn-RuOx active layer is 50:36 :10.

[0038] The preparation method of the carbon fiber-based amorphous Pb-Mn-RuO gradient anode material of the present embodiment, the specific steps are as follows:

[0039] (1) Pretreatment of carbon fiber matrix: firstly remove glue, heat treatment at 500°C under the protection of nitrogen, so that the active specific surface of carbon fiber increases, and at the same time avoid the broken wire damage of ...

Embodiment 3

[0046] The carbon fiber-based amorphous Pb-Mn-RuO gradient anode material of the present embodiment is made of carbon fiber substrate, Ni-Co coated on the carbon fiber substrate 3 o 4 The bottom layer, the Sn-Co-RuOx intermediate layer covering the bottom layer, and the amorphous Pb-Mn-RuOx active layer covering the Sn-Co-RuOx intermediate layer. Among them Ni-Co 3 o 4 Co in the composite coating 3 o 4 The composition is 2.85wt%, the Sn:Co:Ru molar ratio in the Sn-Co-RuOx coating is 54:18:1; the Pb:Mn:Ru molar ratio in the amorphous Pb-Mn-RuOx active layer is 42: 24:12.

[0047] The preparation method of the carbon fiber-based amorphous Pb-Mn-RuO gradient anode material of the present embodiment, the specific steps are as follows:

[0048] (1) Pretreatment of the carbon fiber matrix: firstly remove the glue, and heat the carbon fiber matrix at 800°C under the protection of nitrogen to increase the active specific surface of the carbon fiber and avoid the broken filaments...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com