Composite technology of spraying self-fluxing alloy combined with medium frequency induction heating to produce wear-resistant sealing surface of valves

A self-fluxing alloy and valve sealing technology, which is applied in the field of composite technology, can solve the problems of high dilution rate of plasma spray welding layer, high price of bonding wear-resistant ring technology, damage to adhesive sealing surface, etc., and achieve deposition efficiency High, low production cost, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

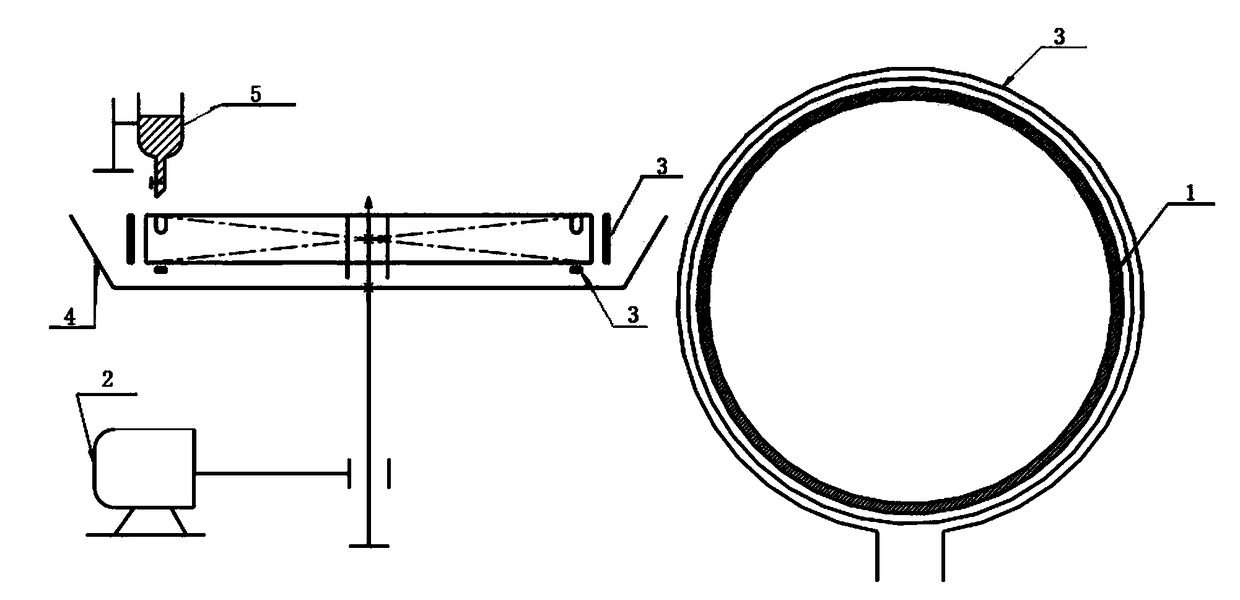

[0021] Such as figure 2 As shown, the equipment used for feeding and medium frequency induction heating cladding includes a positioner (2), a medium frequency induction heating coil (3), a tray (4) and a powder filler (5). The pallet is installed horizontally on the positioner and can rotate horizontally. The sealing surface of the valve is placed on the pallet. The intermediate frequency induction coil is installed on the horizontal and vertical planes of the pallet as shown in the figure. The coil can be heated around the annular groove of the workpiece. The funnel mouth of the powder filler It is fixed directly above the annular groove of the workpiece, so that when the positioner rotates horizontally, the self-fluxing alloy powder falls vertically into the annular groove on the sealing surface of the valve.

[0022] A composite process for producing wear-resistant sealing surfaces of valves by spraying self-fluxing alloys combined with medium-frequency induction heating, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com