Preparation method of abrasion-resistant hydrophobic coating

A technology of hydrophobic coating and bottom layer, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., and can solve the problem of poor wear resistance of hydrophobic coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

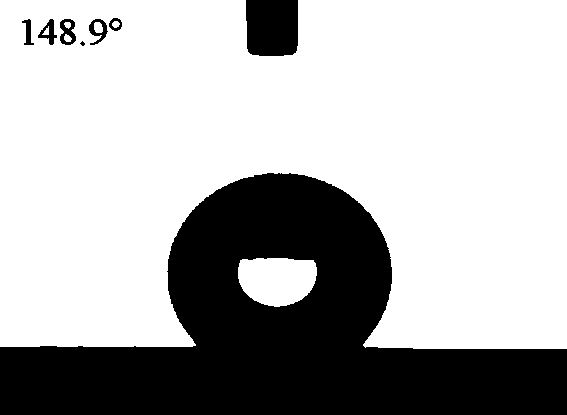

Embodiment 1

[0013] Use kerosene, alcohol, and acetone to degrease the substrate in turn, and then use No. 46 corundum sand to sandblast and roughen the surface of the aluminum alloy substrate to improve the bonding strength of the coating; first, use atmospheric plasma spraying technology, use AT:PFA =1:3 mixed powder spraying bottom layer, spraying distance 110mm, current 630A, Ar flow rate 45L / min, H 2 The flow rate is 10L / min, the powder feeding rate is 35g / min, and the coating thickness is 90μm; then, supersonic flame spraying is used to spray the surface layer with AT:PFA=3:1 mixed powder, the gasoline flow rate is 13L / min, and the oxygen flow rate is 900L / min , the powder feeding rate is 45g / min, and the coating thickness is 24μm.

Embodiment 2

[0015] Use kerosene, alcohol, and acetone to degrease the substrate in sequence, and then use No. 46 corundum sand to sandblast and roughen the surface of the aluminum alloy substrate; first, use atmospheric plasma spraying technology to spray with AT:PFA=1:3 mixed powder Bottom layer, spraying distance 90mm, current 600A, Ar flow 40L / min, H 2 The flow rate is 8L / min, the powder feeding rate is 20g / min, and the coating thickness is 88μm; then, supersonic flame spraying is used to spray the surface layer with AT:PFA=3:1 mixed powder, the gasoline flow rate is 10L / min, and the oxygen flow rate is 700L / min , powder feeding rate 30g / min, coating thickness 25μm.

Embodiment 3

[0017] Use kerosene, alcohol, and acetone to degrease the substrate in sequence, and then use No. 46 corundum sand to sandblast and roughen the surface of the stainless steel substrate; first, use atmospheric plasma spraying technology to spray the bottom layer with AT:PFA=1:3 mixed powder , spraying distance 120mm, current 650A, Ar flow rate 60L / min, H 2 The flow rate is 12L / min, the powder feeding rate is 35g / min, and the coating thickness is 91μm; then, supersonic flame spraying is used to spray the surface layer with AT:PFA=3:1 mixed powder, the gasoline flow rate is 15L / min, and the oxygen flow rate is 900L / min , the powder feeding rate is 50g / min, and the coating thickness is 27μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com