Preparation method of ice coating prevention surface of bionic micro-nano composite structure

A micro-nano composite structure and anti-icing technology, applied in the field of chemistry and materials, can solve the problems of interruption of power and communication, accumulation of ice layer, high toxicity, etc., to reduce the contact area, increase the roughness, and not waste materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Stainless steel is used as the base material, the surface microstructure is bar-shaped helical teeth, and the nanostructure is ZnO nanowires. The preparation steps are as follows:

[0049] The first step is to process the surface microstructure on the surface of the substrate:

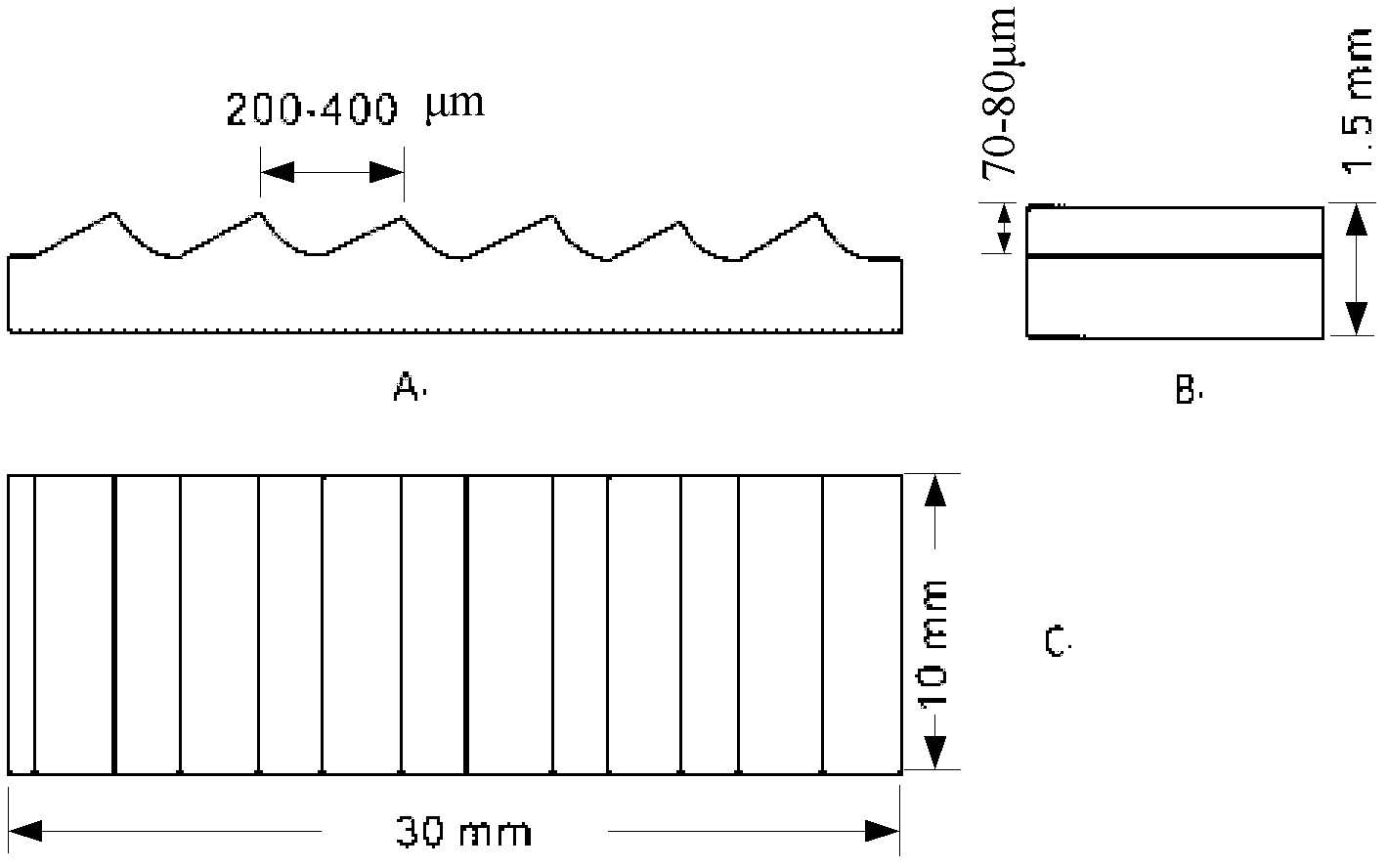

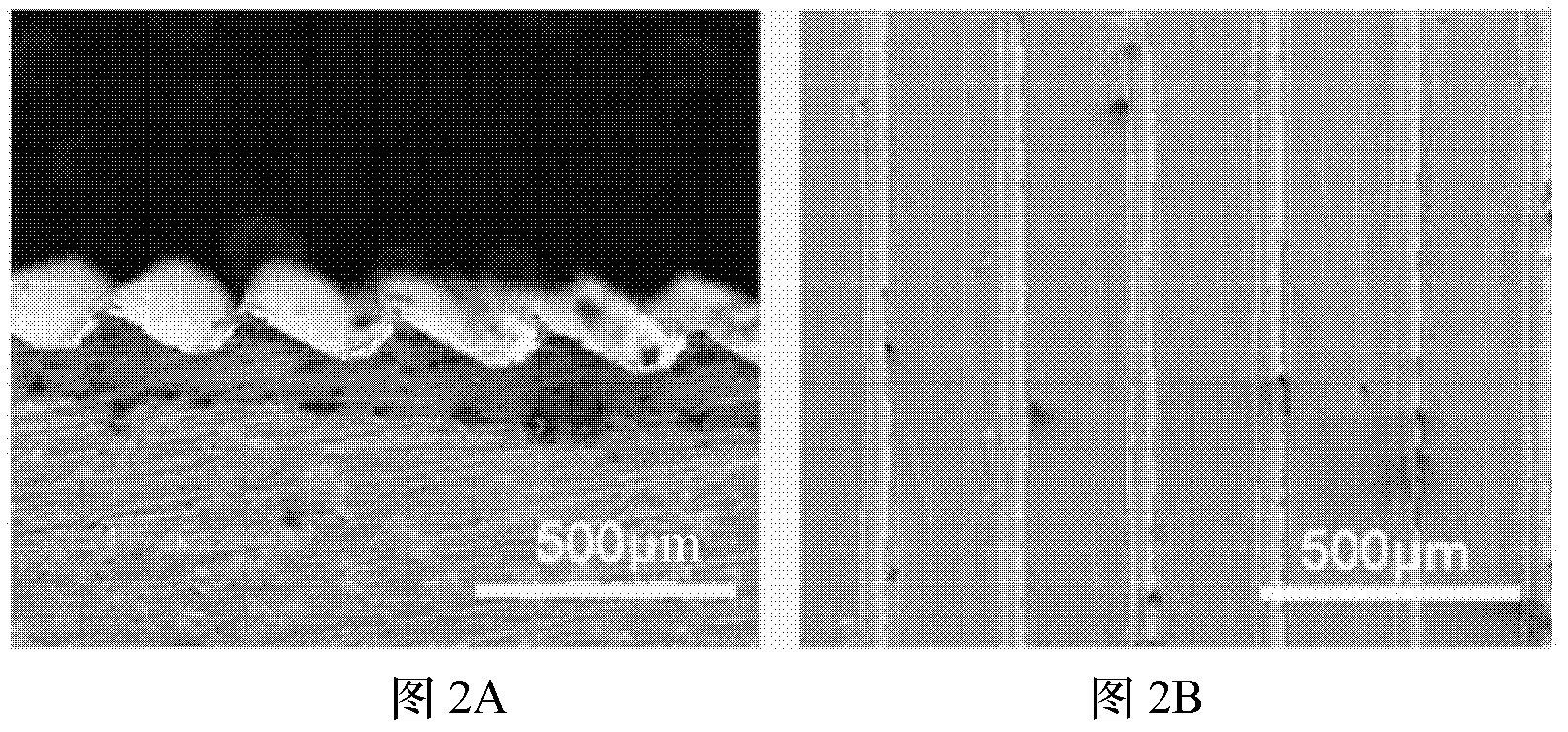

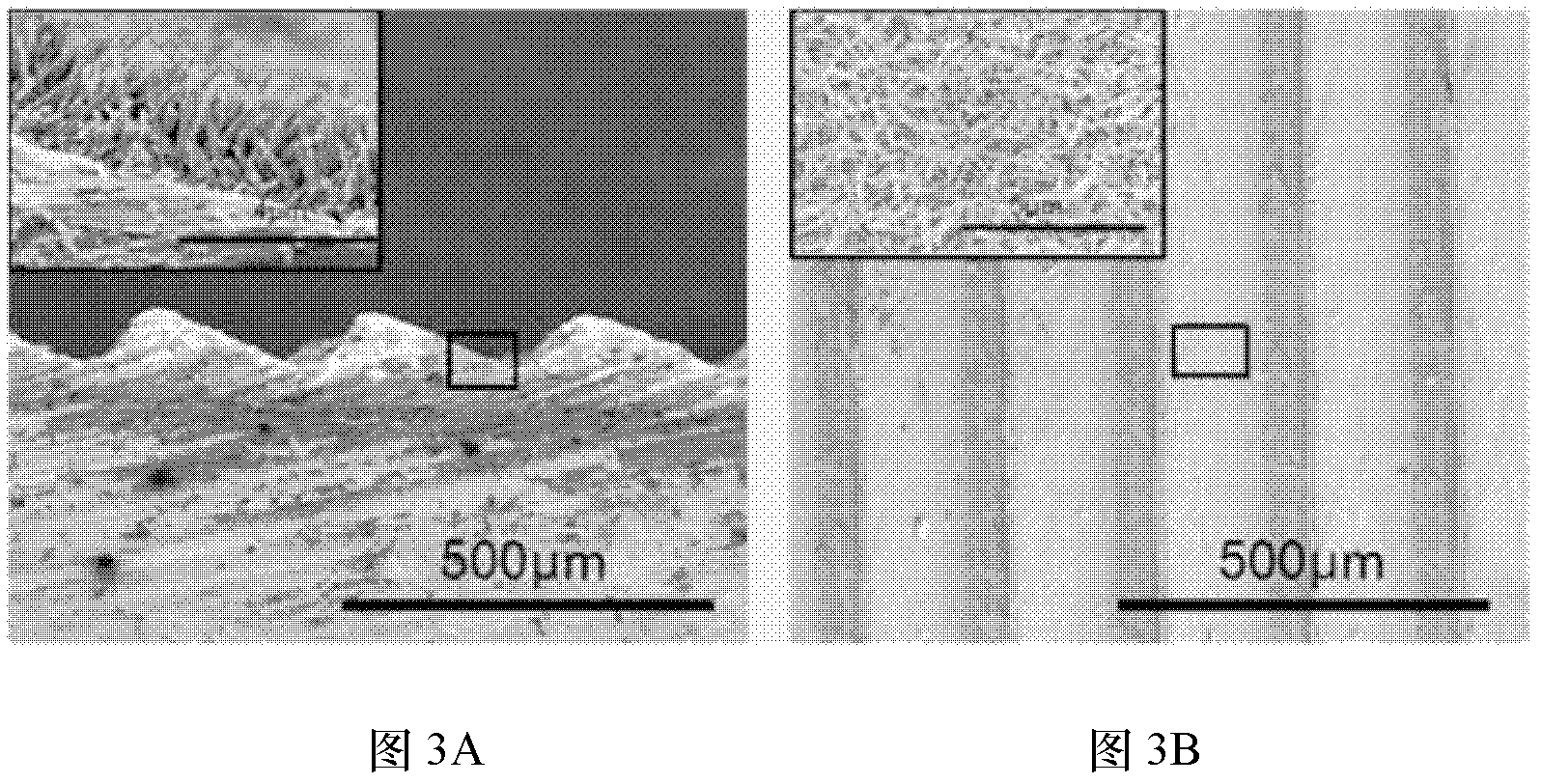

[0050] The strip-shaped helical tooth structure is processed on the surface of the stainless steel substrate by means of mechanical processing. Such as figure 1 As shown, wherein A is the main view, B is the left view, and C is the top view. The length of the base is 30.0mm, the width is 10.0mm, and the height is 1.5mm; The strip-shaped helical tooth structure is parallel to the width direction, the tooth spacing of the strip-shaped helical tooth structure is 200-400 μm, the height is 70-80 μm, and the inclination angle of the strip-shaped helical teeth is 25-30°. The scanning electron microscope picture of the surface micron structure is as follows Figure 2A , 2B , Figure 2A ...

Embodiment 2

[0065] The first step is the topography processing of the substrate surface:

[0066] The matrix helical tooth structure is processed on the surface of the base, and the base is made of pig iron material, such as Figure 5 As shown, the length of the base is 21.5mm, the width is 11.5mm, and the height is 3.0mm. The angle is 40-45°; the helical tooth period in the width direction is 0.4-1.0mm, and the inclination angle is 30-40°. The optical picture of the matrix helical tooth structure is as follows Figure 6A , 6B as shown, Figure 6A is the front view, Figure 6B It is a top view, and it can be seen from the figure that the surface of the substrate forms a matrix helical tooth structure surface with a micron structure.

[0067] In the second step, nanostructures are grown on the surface microstructures:

[0068] The same method as in Example 1 is used to plant ZnO nanowires on the surface microstructure surface, and the scanning electron microscope picture and planting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com