Ultra-thin steel structure fire-resistant coating material with multi-core structure

A steel structure, ultra-thin technology, applied in fireproof coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of unsightly appearance and frequent painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Fireproof antirust primer:

[0050] Potassium silicate resin: 12

[0055] Bismuth oxide: 1

[0056] Sodium oxide: 0.2

[0057] Silica: 10

[0058] Alumina: 2

[0059] Dispersant: 0.8

[0060] Water: up to 100

[0061] Fireproof middle coat paint:

[0062] Melamine formaldehyde resin: 50

[0063] Expandable graphite composite phosphorus nitrogen flame retardant: 15

[0064] Titanium dioxide: 10

[0065] Talc: 8

[0066] Dispersant: 5

[0067] Thickener: 3

[0068] Water: add water to 100

[0069] Fireproof finish:

[0070] Hydroxy Acrylic: 15

[0071] Polyammonium phosphate: 20

[0072] Titanium dioxide: 20

[0075] Coalescent: 2

[0076] Water: Appropriate amount to 100

experiment example

[0077] Experimental example: actual construction example, the coating used for coating is the coating prepared in Example 1.

[0078] Primer layer: Brush the fireproof and antirust primer once, and the dry film thickness is 0.15mm.

[0079] Intermediate coat: Apply fireproof intermediate coat paint 3-4 times, with a total dry film thickness of 1.6mm.

[0080] Topcoat layer: apply fireproof topcoat 2 times, total dry film thickness 0.20mm

[0081] Total dry film thickness: 1.95mm

[0082] Fire resistance time limit: 2 hours (GB14907-2002)

[0083] Experimental results show that: the ultra-thin steel structure fire-resistant coating with multi-core structure of the present invention can form a fire-resistant coating with thinner coating thickness, higher fire-resistant time limit and good decorative effect on the steel structure, and It fully complies with the fire resistance standard of GB14907-2002.

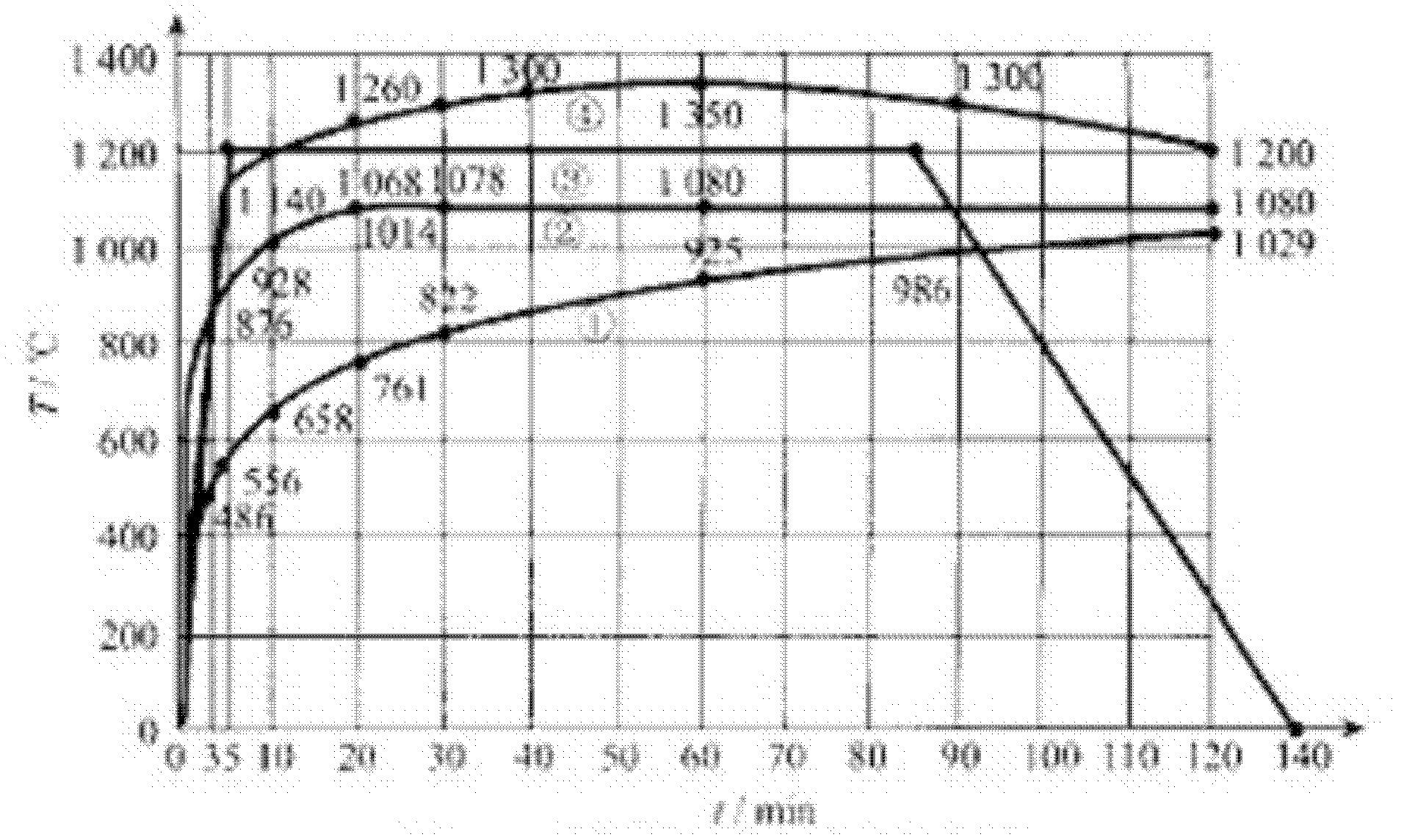

[0084] The primer layer of this example swells at 580°C. The middle coa...

Embodiment 2

[0086] Fireproof antirust primer:

[0087] Sodium silicate resin: 15

[0088] Zinc Dust: 20

[0089] Zinc Oxide: 3

[0090] Titanium oxide: 10

[0092] Bismuth oxide: 5

[0093] Sodium oxide: 0.5

[0094] Silica: 8

[0095] Alumina: 8

[0096] Dispersant: 0.4

[0097] Thickening and leveling agent: 0.6

[0098] Water: up to 100

[0099] Fireproof middle coat paint:

[0100] Urea-formaldehyde resin: 10

[0101] Expandable graphite composite phosphorus nitrogen flame retardant: 35

[0102] Titanium dioxide: 20

[0103] Talc: 5

[0104] Water: up to 100

[0105] Fireproof finish:

[0106] Epoxy: 30

[0107] Polyammonium phosphate: 10

[0108] Titanium dioxide: 10

[0109] Zinc oxide: 10

[0111] Dispersant: 2

[0112] Wetting agent: 2

[0113] Coalescing aid: 0.5

[0114] Thickener: 2.5

[0115] Fungicide: 1

[0116] Water: Add appropriate amount to 100

[0117] The coating prepared in Example 2 wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com