Method for finishing V-shaped sharp angle of metal-base diamond grinding wheel by electrical discharge grinding in gas

A diamond grinding wheel and metal technology, which is applied to metal processing equipment, parts of grinding machine tools, grinding/polishing equipment, etc., can solve the problems of low efficiency of grinding stone dressing methods and difficulty of high precision for metal-based diamond grinding wheel tools. Achieve the effect of being beneficial to environmental protection, improving dressing efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

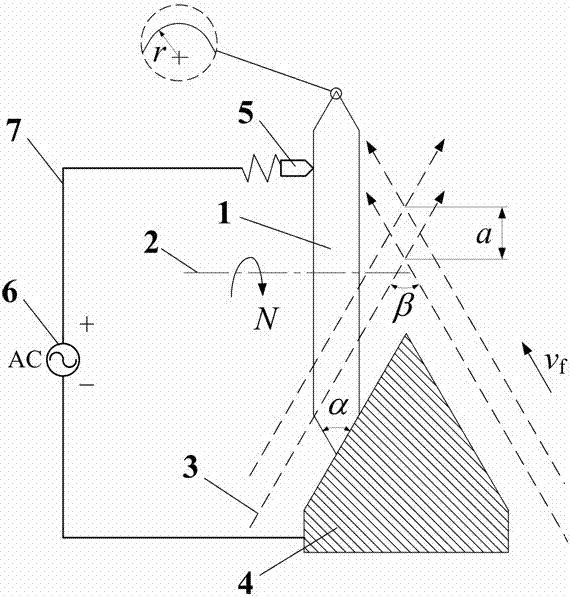

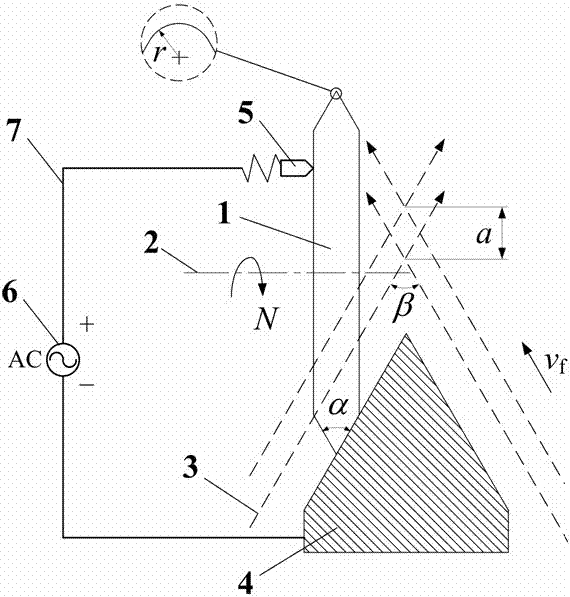

[0022] A diamond grinding wheel tool 1 with a diameter of 150mm is installed on a CNC precision grinder (SMRART B818). The rectangular electrode 4 is consistent with the axis of the grinding wheel along the electrode thickness on the worktable, and is consistent with the diamond grinding wheel tool 1, graphite brush 5, SMC-5S / J double pulse power supply 6 and wire 7 form a discharge circuit. The size of the diamond grinding wheel is 600 mesh, the bonding agent is bronze, and the concentration is 100, which is 4.4 carats / cm. 3 . The electrode 4 is a mixture of bronze and silicon carbide abrasive, and the silicon carbide abrasive has a particle size of 600 mesh.

[0023] Such as figure 1 As shown, the V-shaped walking path angle β of the grinding wheel is designed to be 60 degrees, the grinding wheel speed N=3826 rpm, and the grinding wheel feed speed v f It is 200 mm / min, the cross V-shaped walking path is fed for 3 minutes and 50 times, the feed depth a is 3 microns, the pulse n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com