Electrolytic in-process dressing device of concave spherical surface of spherical coupling

A technology for dressing devices and concave spherical surfaces, which is applied in the direction of spherical grinding machines, grinding drive devices, and parts of grinding machine tools, can solve the problems of difficult spraying of grinding fluid for grinding wheel dressing, complex shape of dressing electrodes, etc., and achieves simple structure and easy Uniform operation and spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

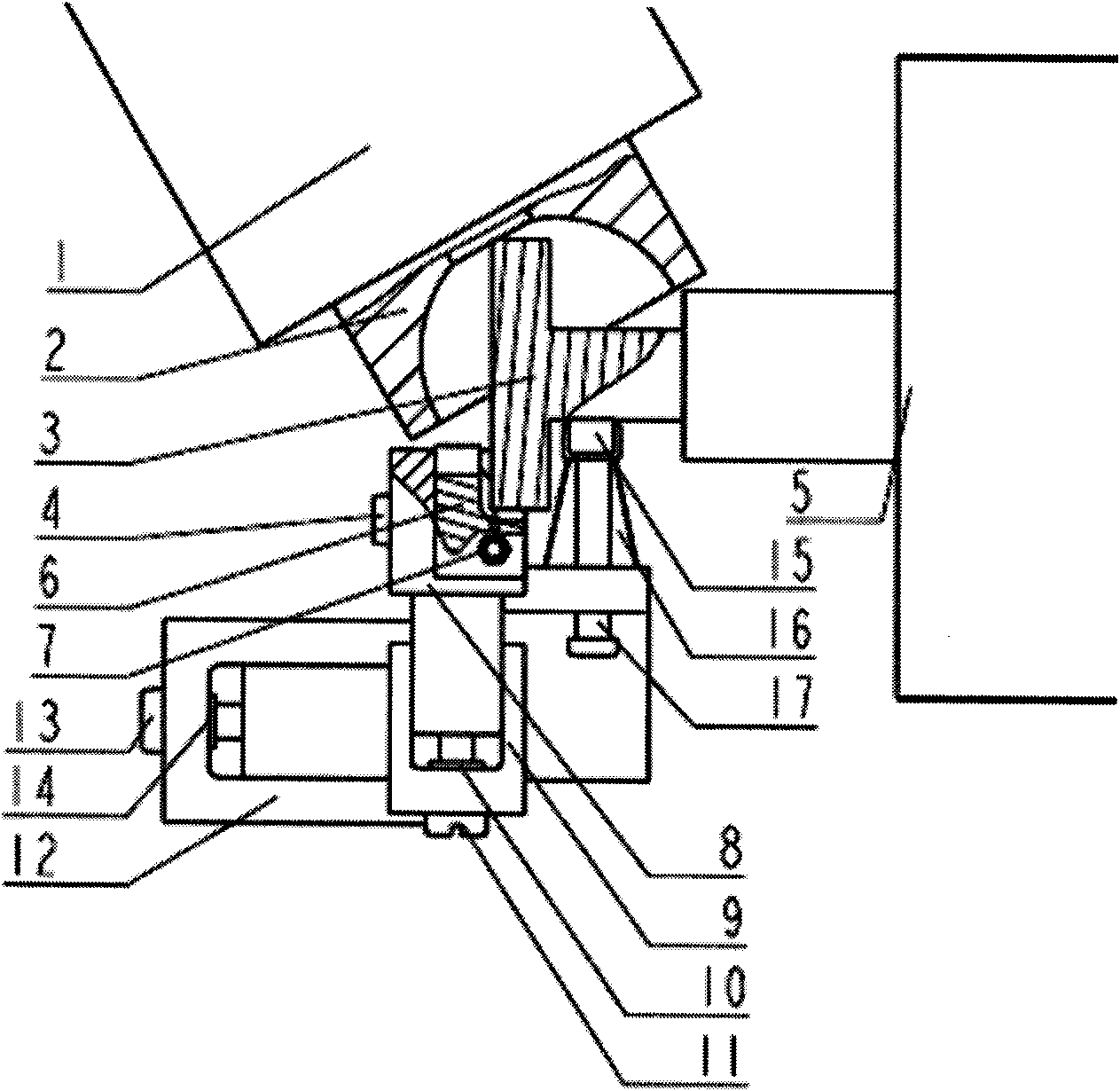

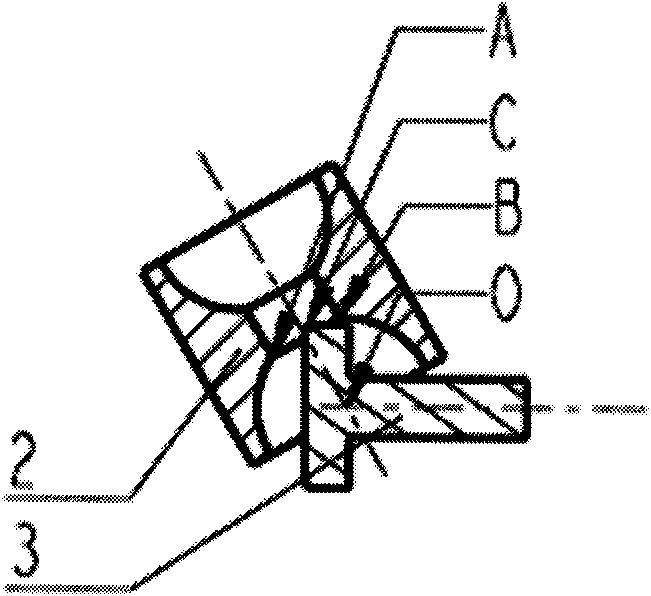

[0014] Such as figure 1 As shown, the on-line electrolytic trimming device for the concave spherical surface of the spherical couple of the present invention is composed of a workpiece spindle 1, a grinding wheel 3, a trimming electrode fixing screw 4, an electric spindle 5, a trimming electrode 6, a pipe joint 7, a trimming electrode seat 8, a gap adjustment device, and an electric motor. The composition of the brush device. The workpiece spindle 1 and the electric spindle 5 are placed on the corresponding slide plate of the grinding machine, the ball bowl workpiece 2 is placed in the workpiece spindle 1, and the grinding wheel 3 is placed in the electric spindle 5. The trimming electrode 6 is fixed on the trimming electrode holder 8 by the trimming electrode fixing screw 4, and the pipe joint 7 is connected with the trimming electrode 6 through threads.

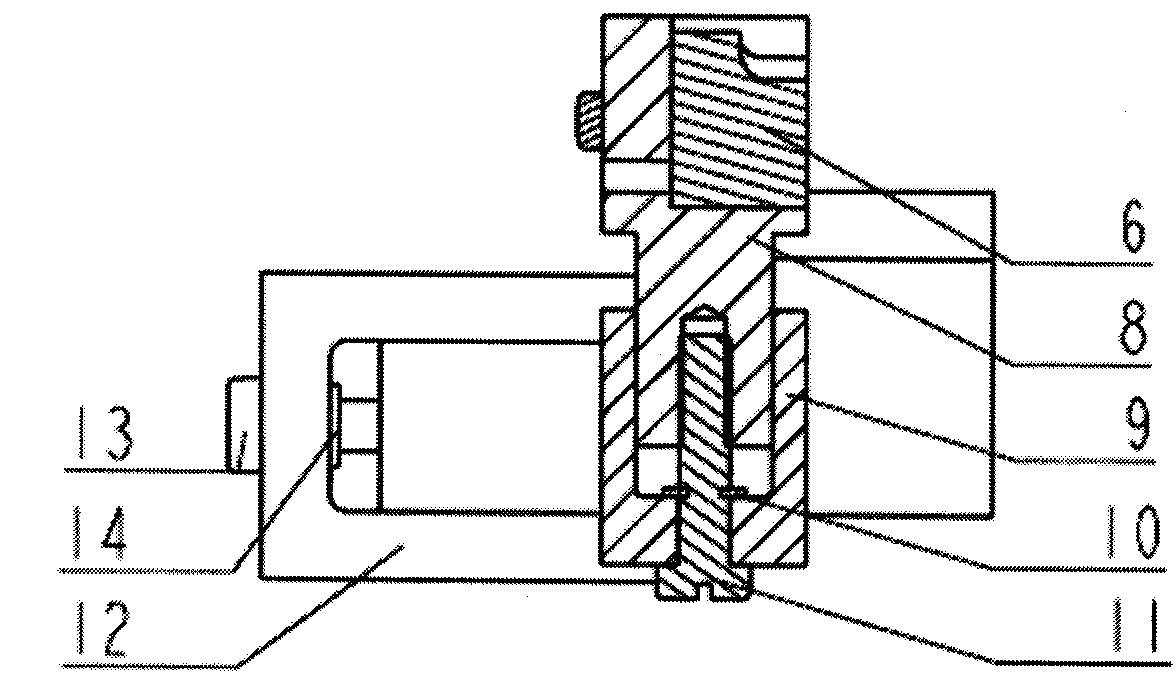

[0015] Such as figure 2 As shown, the clearance adjustment device is composed of a radial clearance adjustment member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com